Automatic temperature control liquor brewing tank

An automatic temperature control and wine-making tank technology, which is applied in the preparation of wine, alcoholic beverages, biochemical equipment and methods, etc., can solve problems such as poor technical effect, uneven temperature rise, and difficulty in temperature adjustment of wine tank fermentation, and achieve Low cost, stable and uniform temperature rise, and flexible heating methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

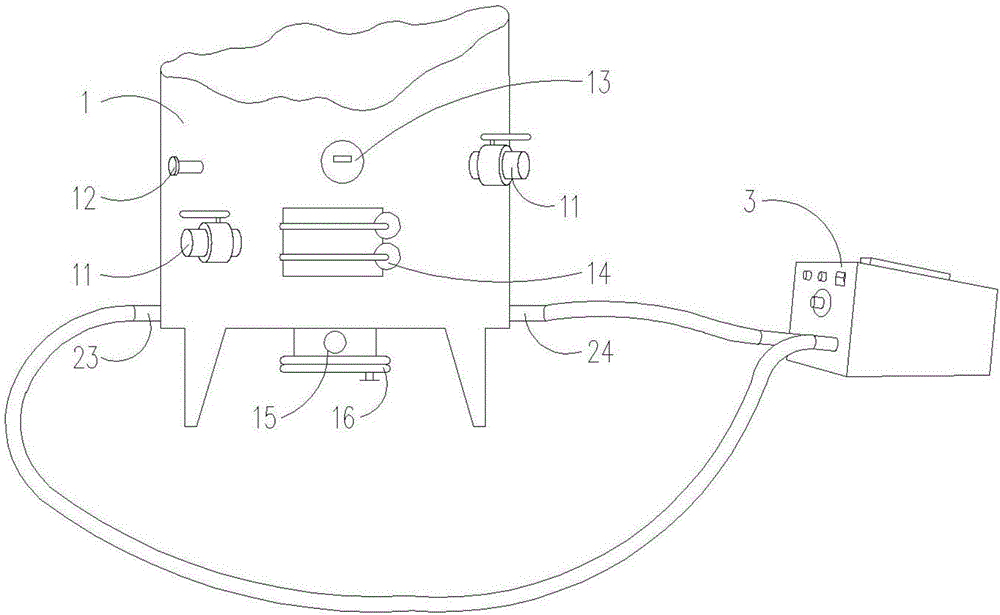

Image

Examples

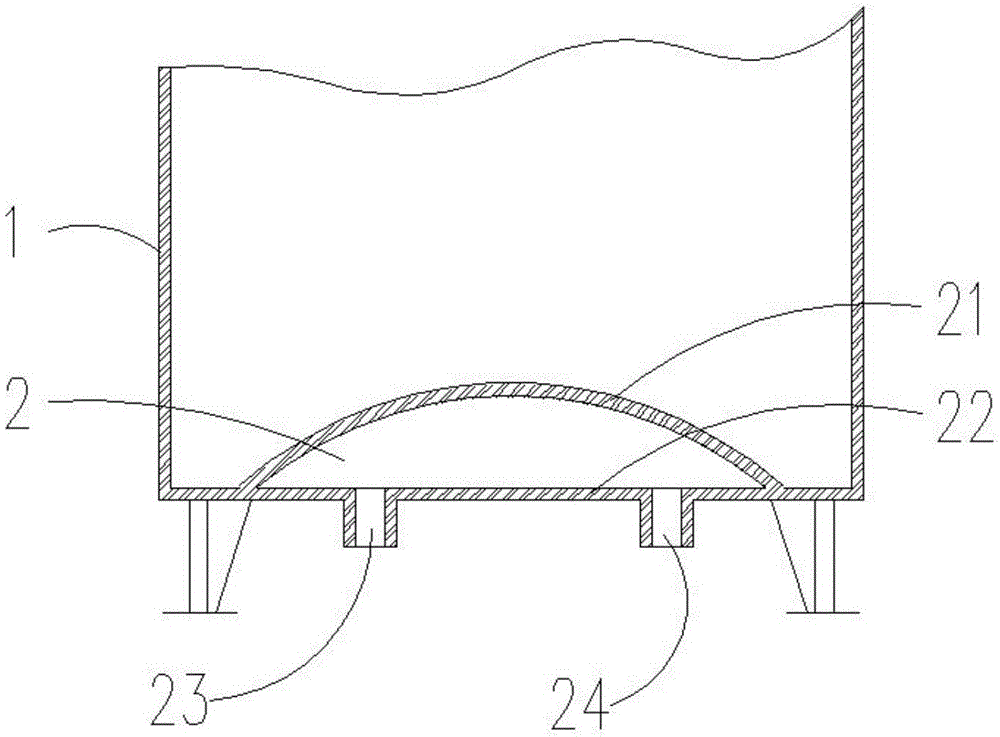

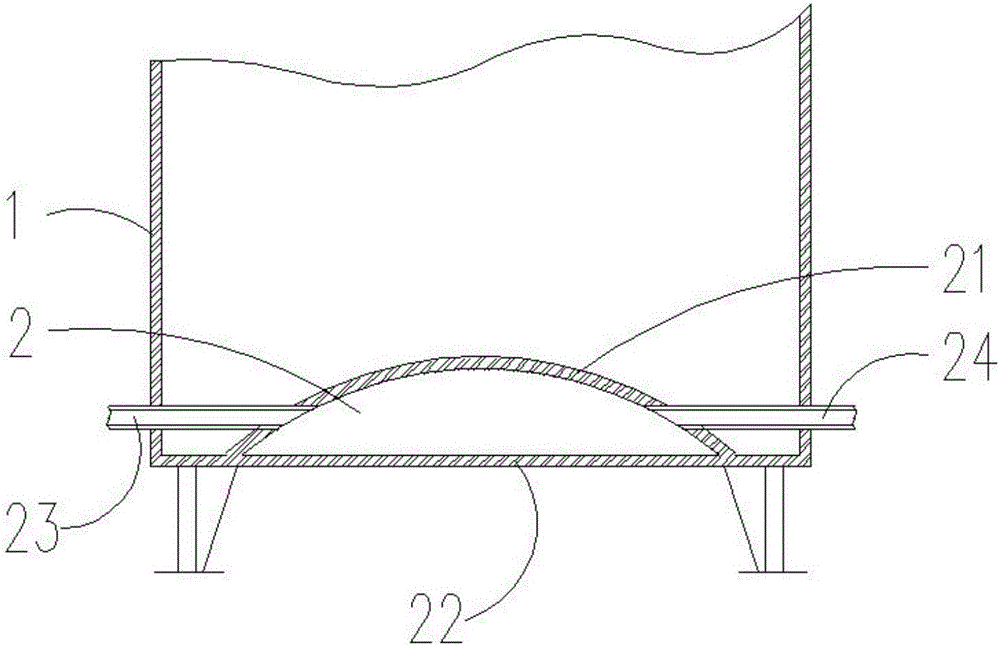

Embodiment 1

[0027] as attached Figure 4 As shown, a fully loaded 5-ton wine tank is separately connected to the intelligent heating device 3 to form a circulation pipeline, and the original temperature of the electronic thermometer 13 on the tank wall 1 is 4°C. Set the heating temperature of the intelligent heating device 3 to 20°C, start the cycle, the water in the heat medium chamber 2 is heated to 20° by the intelligent heating device 3, and then the constant temperature continues to circulate, and the wine tank is heated by the heat conduction of the sandwich plate 21 of the heat medium chamber 2. For internal fermented wine, the wine body in the 5-ton tank heats up at a heating rate of 1°C per hour, and the temperature in the tank can be raised to 15°C in 10 hours, and the temperature in the tank is basically the same up and down. When the electronic thermometer 13 shows that the temperature is 15°C, the heating temperature setting of the intelligent heating device 3 is automaticall...

Embodiment 2

[0029] as attached Figure 5 As shown, four fully loaded 1-ton wine tanks, the heat medium cavity 2 is connected in series with the intelligent heating device 3 through the heat medium inlet 23 and the heat medium outlet 24 in turn to form a circulation pipeline, and the tank walls of the four wine tanks are connected in series. The original temperature of the electronic thermometer 13 on 1 is about 6°C. Set the heating temperature of the intelligent heating device 3 to 20°C, start the cycle, the water in the heat medium chamber 2 is heated to 20° by the intelligent heating device 3, and then the constant temperature continues to circulate, and the wine tank is heated by the heat conduction of the sandwich plate 21 of the heat medium chamber 2. For internal fermented wine, the temperature in the tank can be raised to 15°C in 8 hours, and the temperature rise rate in the four wine tanks is basically the same. When the electronic thermometers 13 on the walls 1 of the four wine ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com