Air suction valve and compressor

A suction valve and reed technology, applied in the field of refrigeration compressor accessories, can solve the problems of reducing the suction efficiency of the suction valve 001, reducing the structural strength of the reed 110, and the unbalanced force of the reed 110, etc., to achieve Effects of reducing force deformation, improving ventilation efficiency, and increasing gap length

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

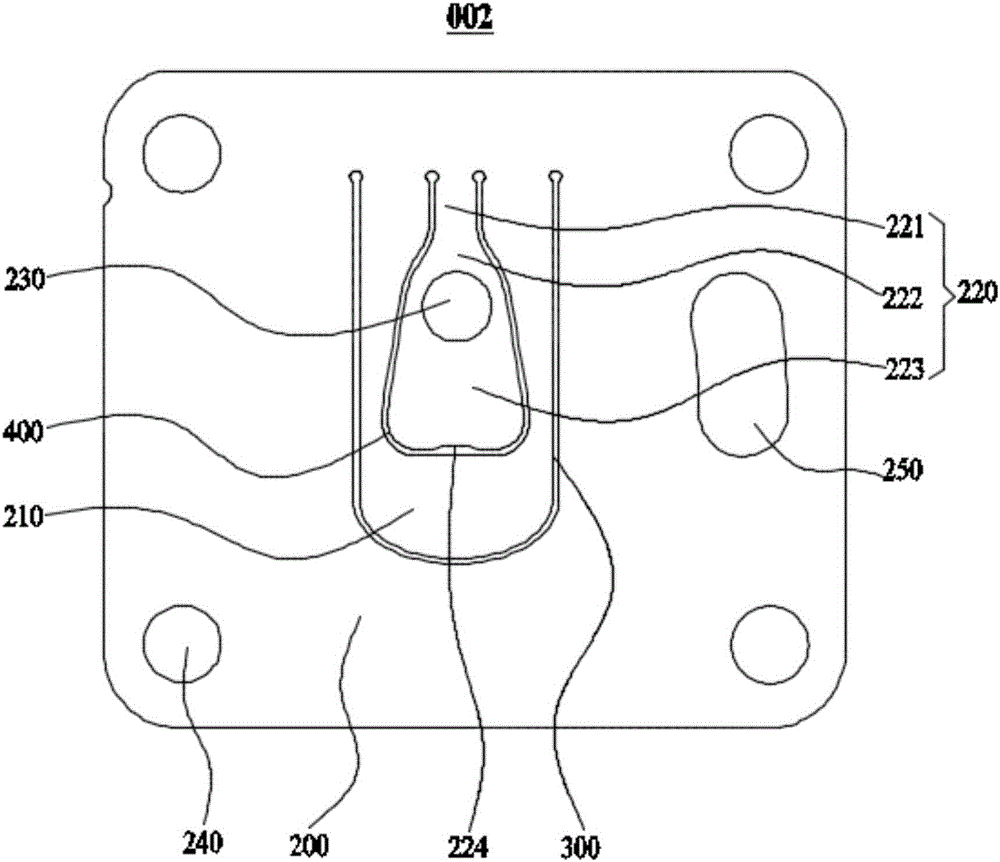

[0032] Such as figure 2 As shown, the present embodiment provides a suction valve plate 002, which includes a valve plate 200, on which a first reed 210 is provided, and a U-shaped first reed 210 is formed between the first reed 210 and the valve plate 200. A ventilation gap 300, the first reed 210 is provided with a second reed 220, a second ventilation gap 400 is formed between the second reed 220 and the first reed 210, and a ventilation hole 230 is opened on the second reed 220 ; The valve plate 200 is provided with a plurality of fixing holes 240 for fixing the valve plate 200 . The length of the first reed 210 is 2-2.2 times of its width, and a positioning hole 250 is opened on the valve plate 200 . Specifically, both the first reed 210 and the second reed 220 are made by stamping, the four corners of the valve plate 200 are respectively provided with a fixing hole 240, and the positioning hole 250 is a bar-shaped hole and is located on one side of the first ventilatio...

Embodiment 2

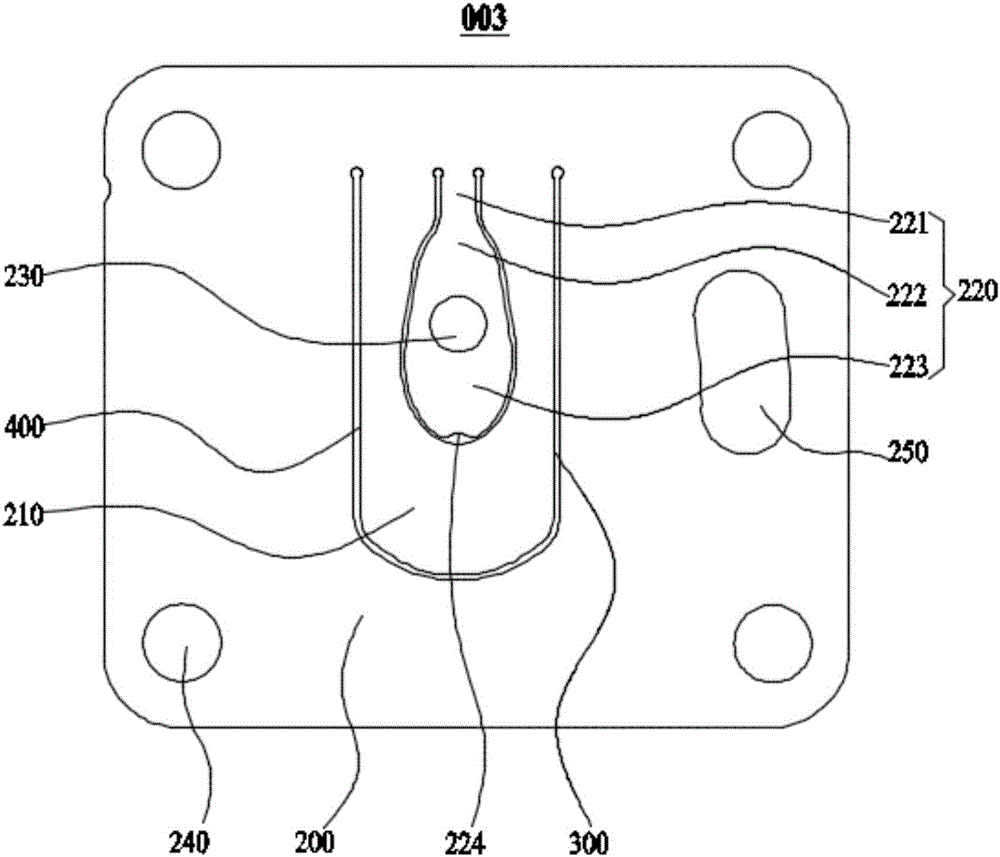

[0042] Such as image 3 As shown, this embodiment provides a suction valve plate 003, which includes a valve plate 200, on which a first reed 210 is provided, and there is a U-shaped first reed between the first reed 210 and the valve plate 200. The ventilation gap 300, the first reed 210 is provided with the second reed 220, the second reed 220 and the first reed 210 have a second ventilation gap 400, and the second reed 220 is provided with a ventilation hole 230; The valve plate 200 is provided with four fixing holes 240 for fixing the valve plate 200 , and the valve plate 200 is provided with a positioning hole 250 . The length of the first reed 210 is 2.2 times its width.

[0043] The second reed 220 includes a fixed part 221, a transition part 222 and a terminal part 223 arranged in sequence, the fixed part 221 is connected with the valve plate 200, and the end edge of the terminal part 223 away from the transition part 222 is provided with a recessed part 224, and the ...

Embodiment 3

[0047] Such as Figure 4 As shown, this embodiment provides a compressor 004 for refrigeration, which is installed with the suction valve plate 002 provided in the first embodiment above.

[0048] The compressor 004 for refrigeration installed with the above-mentioned suction valve plate 002 has high suction efficiency, long service life, low failure rate, and can better meet the use requirements.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com