Self-priming centrifugal pump with automatic closing of return hole

A technology of automatic closing and return hole, which is applied in the direction of driving pumps, components of pumping devices for elastic fluids, pumps, etc., can solve the problems of low pump efficiency, short self-priming time, large leakage, etc., and achieve improvement Efficiency, the effect of shortening the self-priming time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

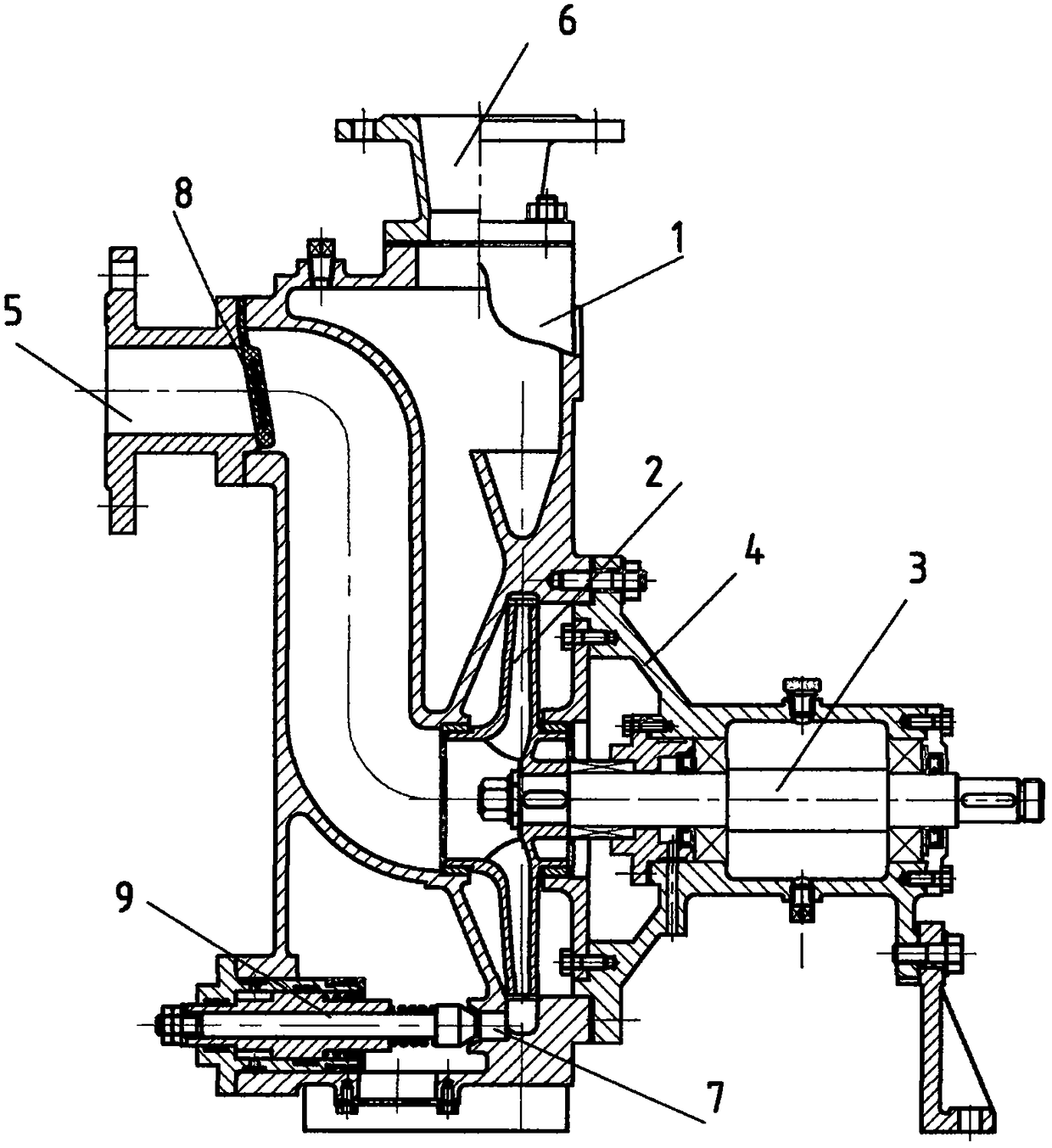

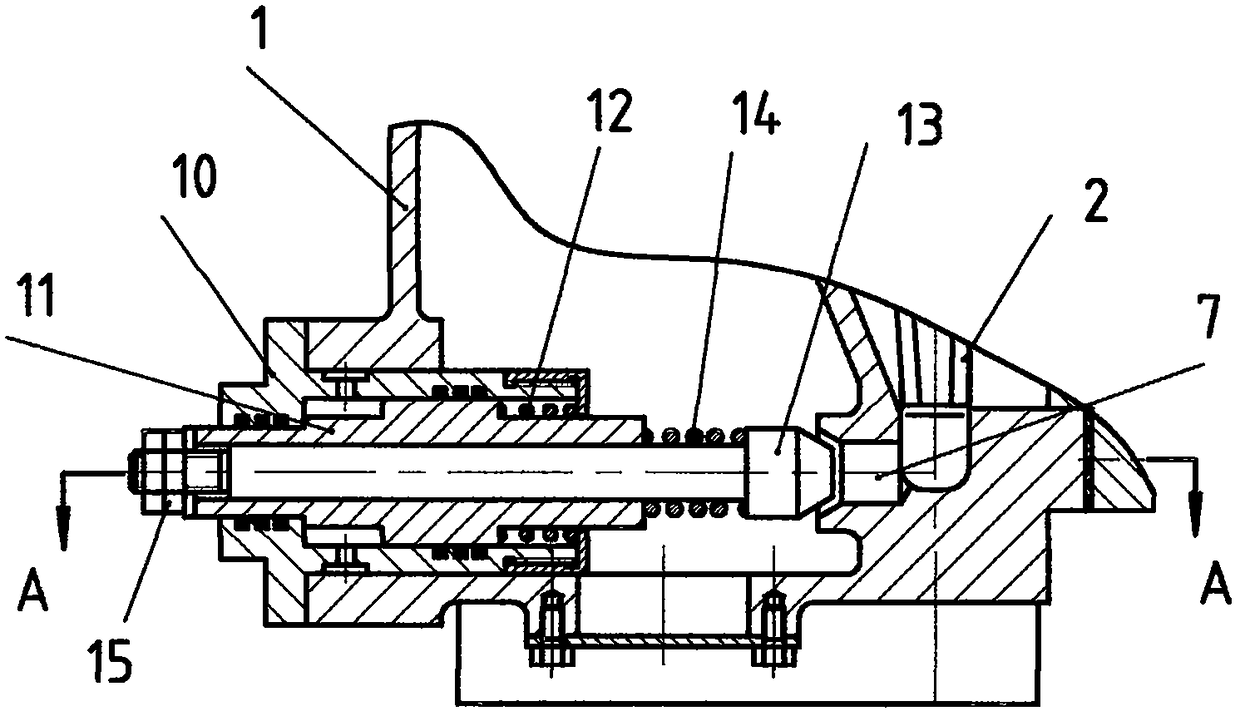

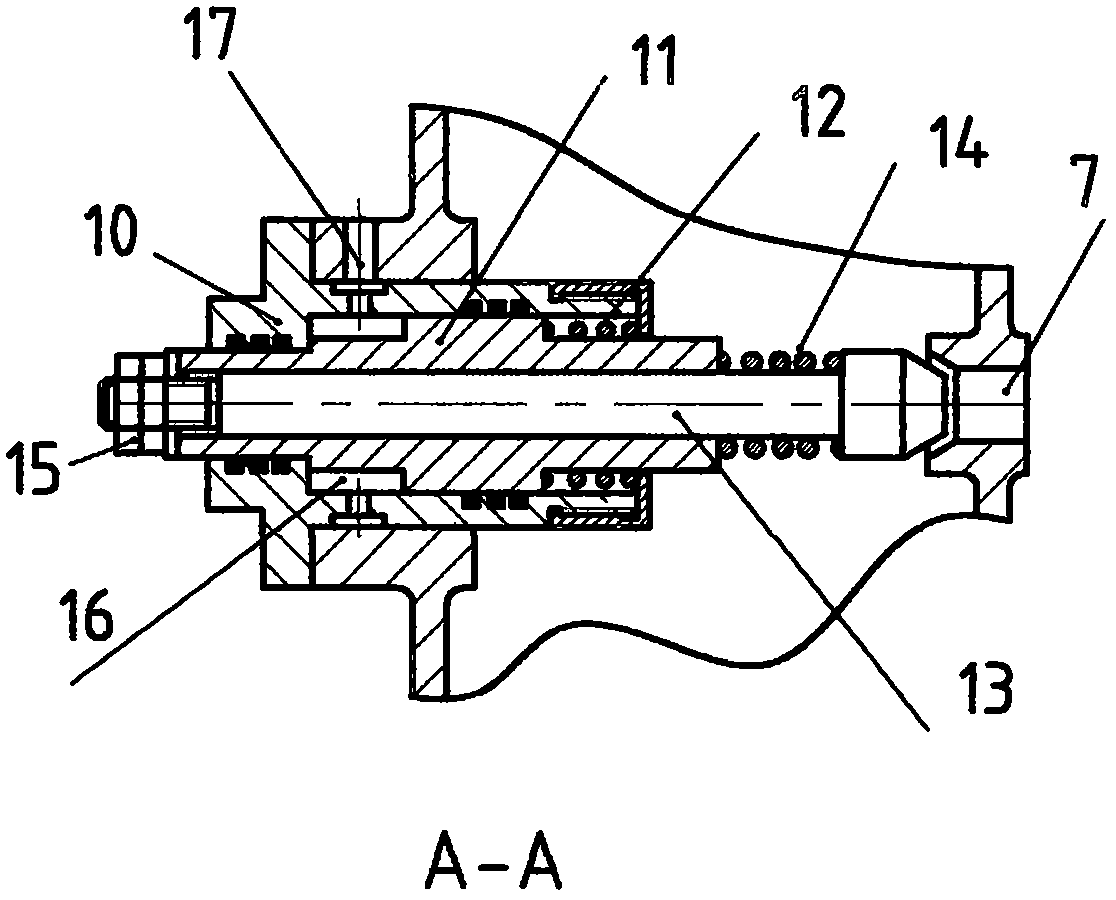

[0016] figure 1 It is a structural diagram of an embodiment of a self-priming centrifugal pump that can automatically close the return hole, figure 2 yes figure 1 The enlarged view of the automatic closing device 9 of the middle backwater hole, image 3 yes figure 2 A-A cutaway view.

[0017] As shown in the figure, the self-priming centrifugal pump whose return hole can be automatically closed includes a pump body 1, an impeller 2 installed in the vortex chamber of the pump body 1, a pump shaft 3 fixedly connected to the impeller 2, and a suspension 4 supporting the pump shaft 3. The pump body 1 is also provided with a suction port 5, a suction channel, a discharge port 6, an air-water separation chamber and a return hole 7. The suction port is provided with a suction check valve 8, and the inlet of the return hole 7 is arranged in an enlarged shape. Cone hole, and a coaxial backwater hole automatic closing device 9 is set directly in front of the backwater hole 7. The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com