Gas-liquid separation device for enhancing self-priming of self-priming multistage centrifugal pump

A technology of gas-liquid separation device and self-priming centrifugal pump, which is applied in the field of gas-liquid separation device and accelerated self-priming multi-stage centrifugal pump gas-liquid separation device, which can solve the problems of poor gas-liquid separation effect, poor self-priming stability, self-priming Slow suction speed and other problems, to achieve the effects of small loss of fluid kinetic energy, increased pressure, and increased air-carrying capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028]The present invention will be further described below with reference to the accompanying drawings and examples.

[0029]Next, a specific embodiment of the present invention is further described with reference to the accompanying drawings, but the present invention is not limited to these embodiments.

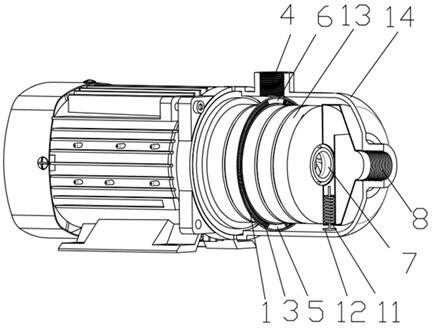

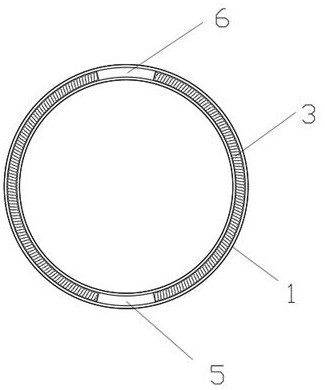

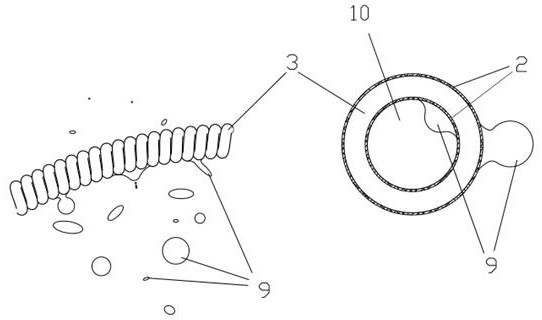

[0030]Such asfigure 1 As shown, the present invention is mounted between the self-suction centrifugal pump to promote the gas-liquid separation device between the pump casing cavity and the pump casing, which is an annular gas-liquid separation device that enhances gas-liquid separation and flow uniformity in the pump housing. . The gas-liquid separation device is composed of an annular spring 3 that is supported from the annular gas separation device and the annular spring 3 of the hydrophobic coating 2, and the annular spring bracket 1 is closely sticked together and is mounted at the centrifugal pump outlet 4.

[0031]Such asfigure 2 As shown, the bottom end of the gas-liquid separati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com