A self-priming pump without water

A self-priming pump and self-priming technology, applied in the direction of driving pumps, pumps, pump components, etc., can solve the problems of restricting the working efficiency of self-priming pumps, prolonging the start-up time, increasing energy consumption, etc., so as to shorten the self-priming time and improve the working efficiency. Efficiency, the effect of improving self-priming efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, but the protection scope of the present invention is not limited thereto.

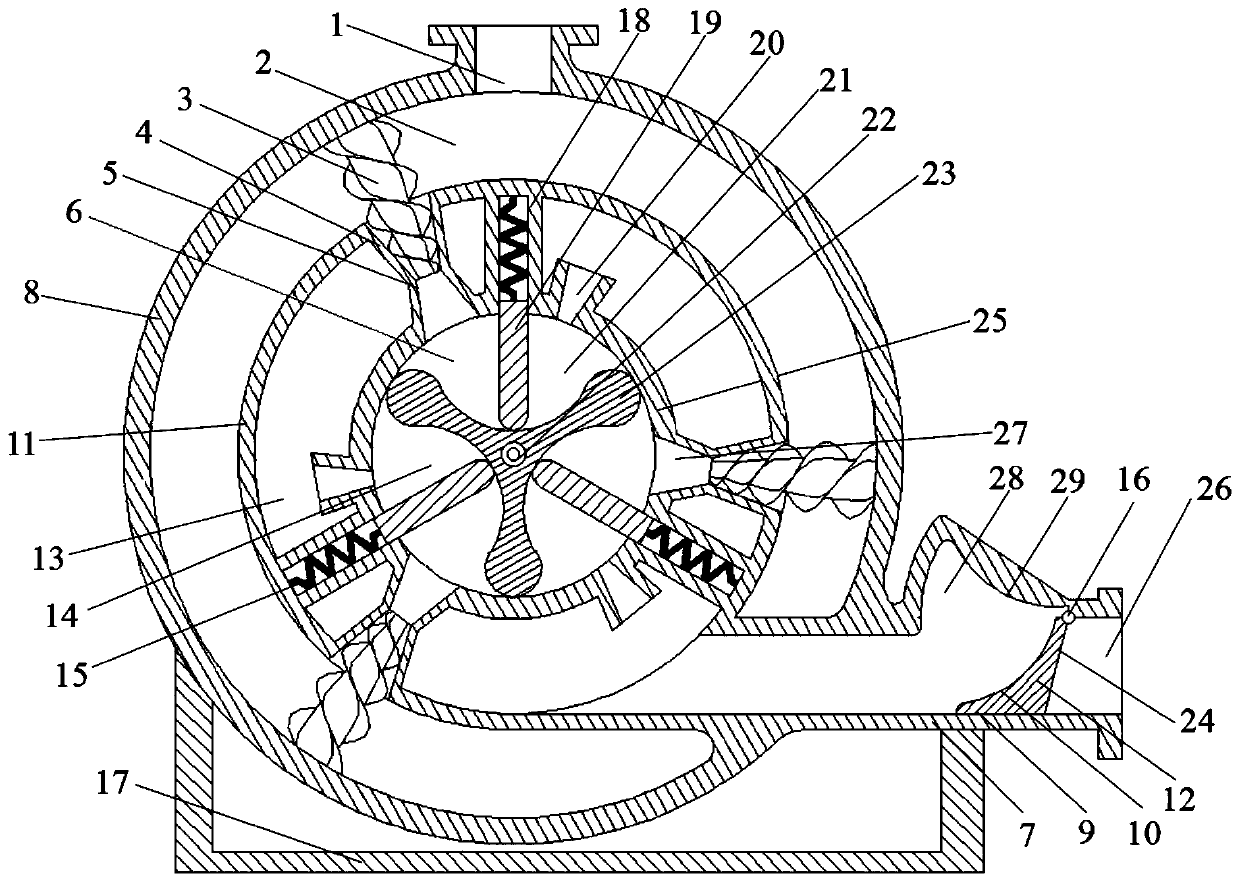

[0026] Such as figure 1 As shown, a kind of anhydrous starting self-priming pump according to the present invention comprises a liquid storage chamber 8, an external self-priming chamber 11 and an internal self-priming chamber 25 arranged in sequence from the outside to the inside, the liquid storage chamber 8, the external self-priming chamber Both the chamber 11 and the inner self-priming chamber 25 are hollow cylindrical, and the ratio of the inner wall diameter of the inner self-priming chamber 25, the inner wall diameter of the outer self-priming chamber 11 to the inner wall diameter of the liquid storage chamber 8 is 1:2:3. Liquid storage chamber 8 is installed on the base 17, and inner self-priming chamber 25 is provided with inner self-priming chamber 14, forms ou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com