Rack connection part installation structure

A technology for connecting parts and mounting structures, applied in the direction of fixing devices, storage devices, mechanical equipment, etc., can solve the problem of low compressive stress intensity and achieve the effect of reduced buckling strength and high compressive strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

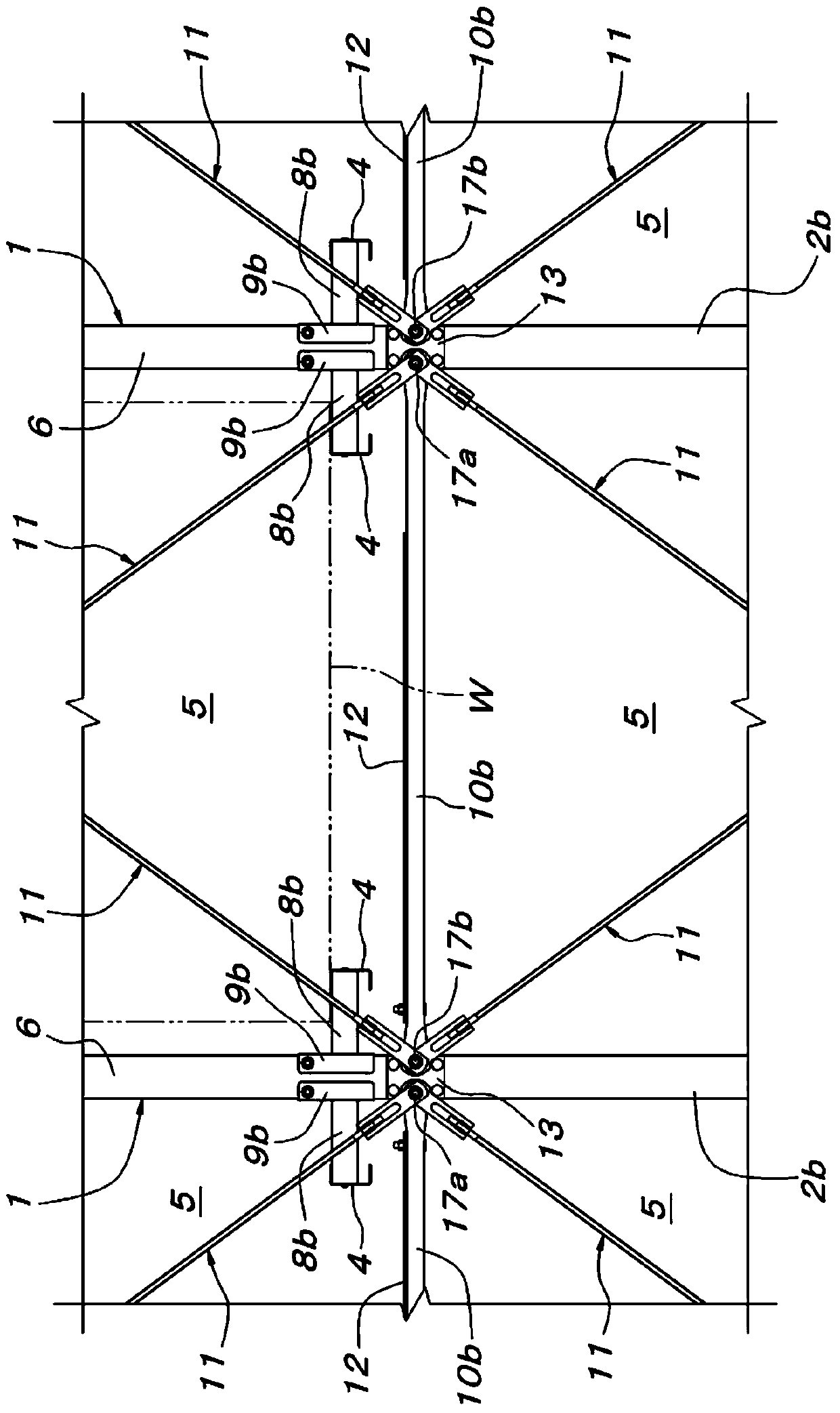

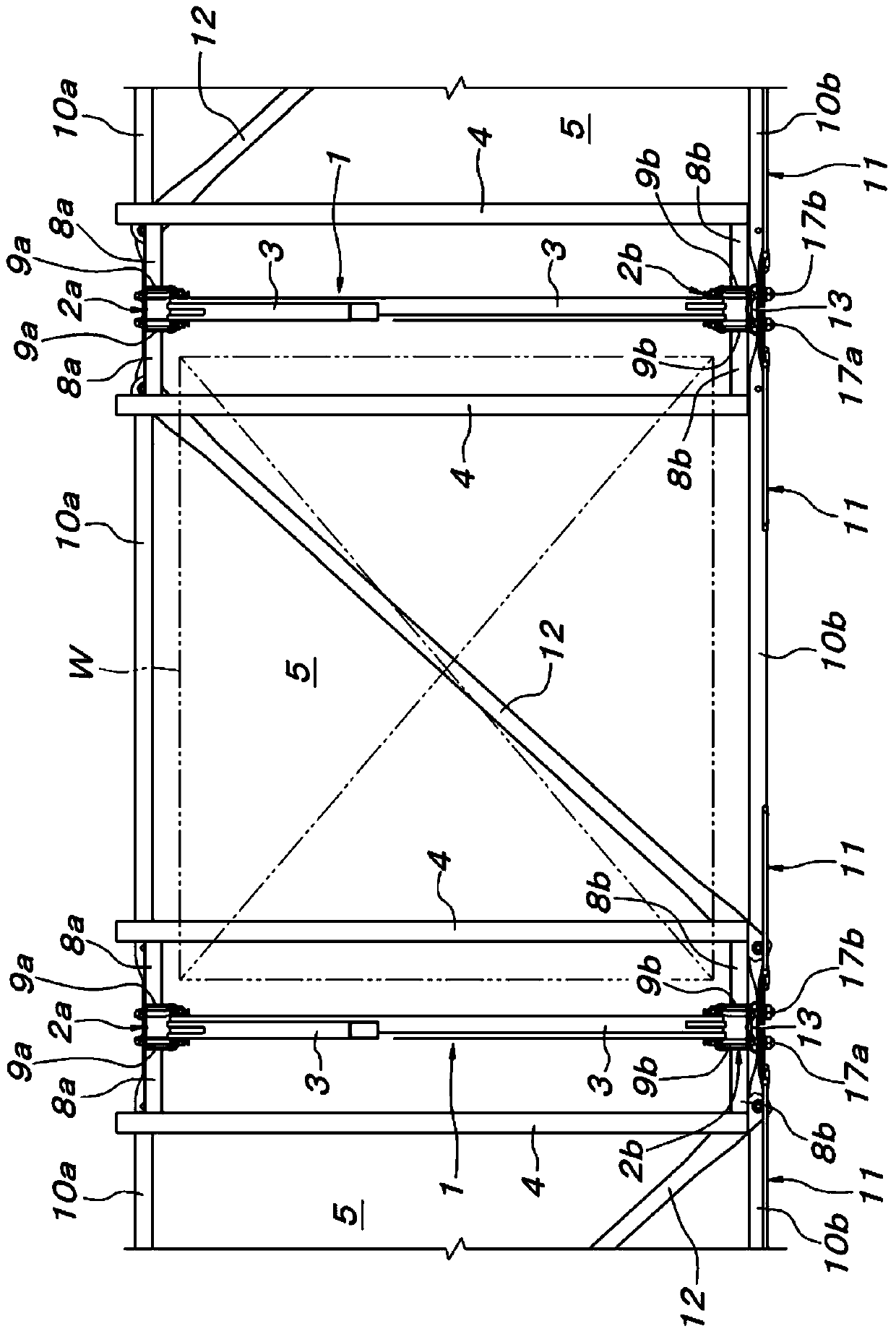

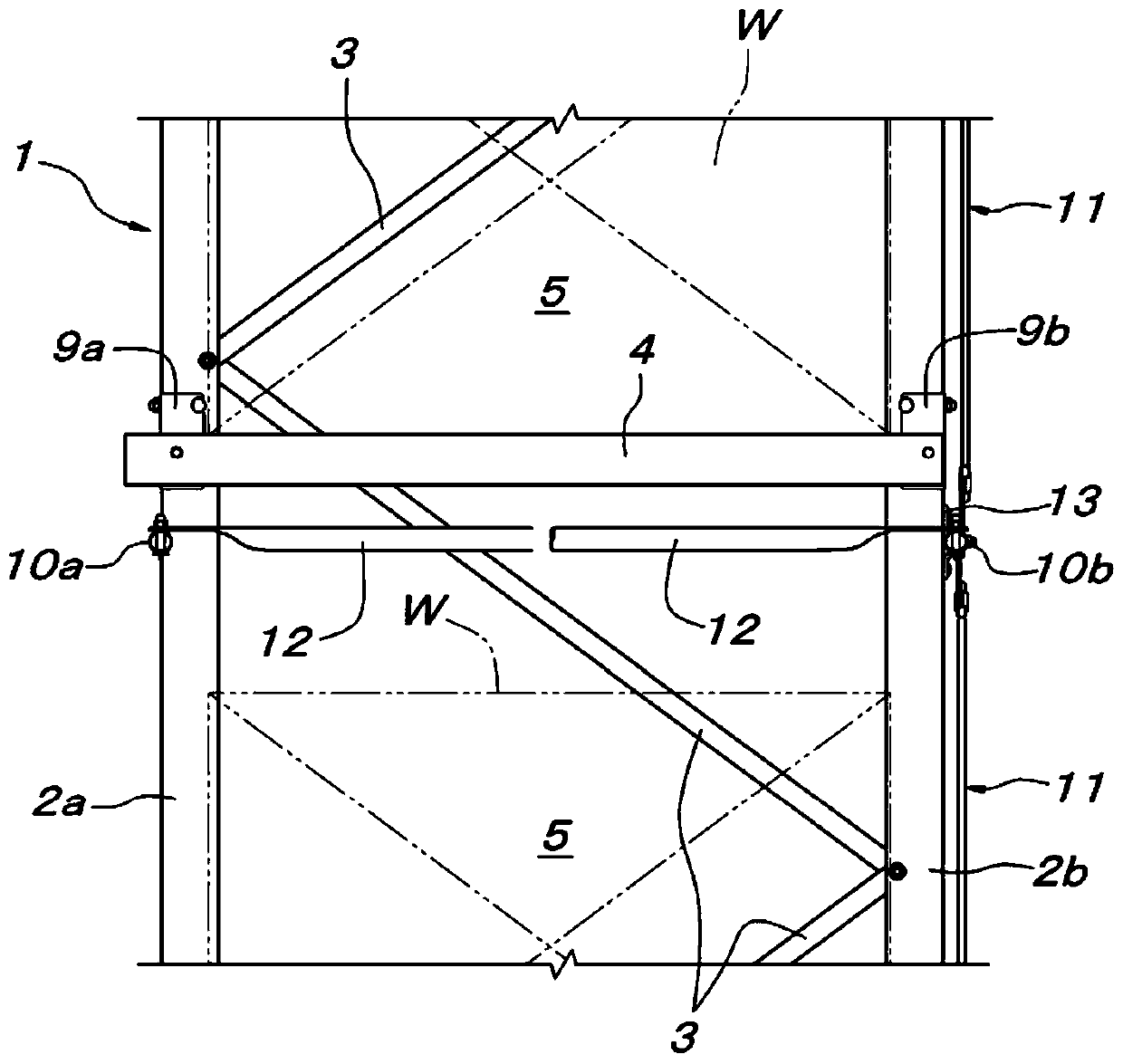

[0052] exist Figure 1 ~ Figure 3 Among them, 1 is a vertical frame structure for partition, which is erected at predetermined intervals in the lateral width direction of the rack. Each partition vertical frame structure 1 is a lattice structure constituted by a pair of front and rear pillars 2a, 2b and a lattice portion 3 that integrally connects the pair of front and rear pillars 2a, 2b. Between the vertical frame structures 1 for separation adjacent to each other in the width direction of the rack, a multi-stage article support section 5 up and down is formed. A pair of left and right article support members 4 for side support. The front and rear pairs of pillars 2a and 2b are formed in a front-rear symmetrical orientation with the front panel 6 and the left and right side panels 7 made of steel. The front and rear ends of each article supporting member 4 are attached to a pair of front and rear columns 2a, 2b via arm portions 8a, 8b parallel to the frame width direction ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com