A flame retardant extruded plastic wallboard

A wallboard, plastic technology, applied in building components, layered products, buildings, etc., can solve the problems of polluted environment, poor bonding performance, easy to fall off, etc. strong effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

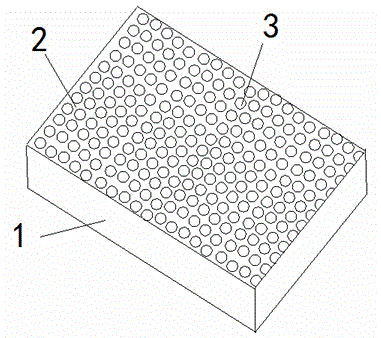

[0013] as shown in the picture 1 As shown, a flame-retardant extruded wallboard according to an embodiment of the present invention includes a thermal insulation matrix 1 , non-combustible layer 2 , foaming 3 , the insulation matrix 1 Located inside the insulation board, the non-combustible layer 2 Wrapped in insulation matrix 1 externally, the foaming 3 with non-combustible layer 2 connect.

[0014] As a preference, the insulation matrix 1 The material is polyethylene.

[0015] As a preference, the foam 3 The internal structure is completely closed and has a honeycomb structure, which is evenly and flatly connected to the surface of the non-stained layer.

[0016] Preferably, the compressive strength of the insulation board is as high as 336Kpa , the thermal conductivity is 0.028W / mk ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Compressive strength | aaaaa | aaaaa |

| Thermal conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com