Locking mechanism and method for an electro-pneumatic controller

一种气动控制器、锁定机构的技术,应用在非电动变量控制、电动方式的流体压力控制、发动机元件等方向,能够解决损坏、安装麻烦、增加无效锁定的概率等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

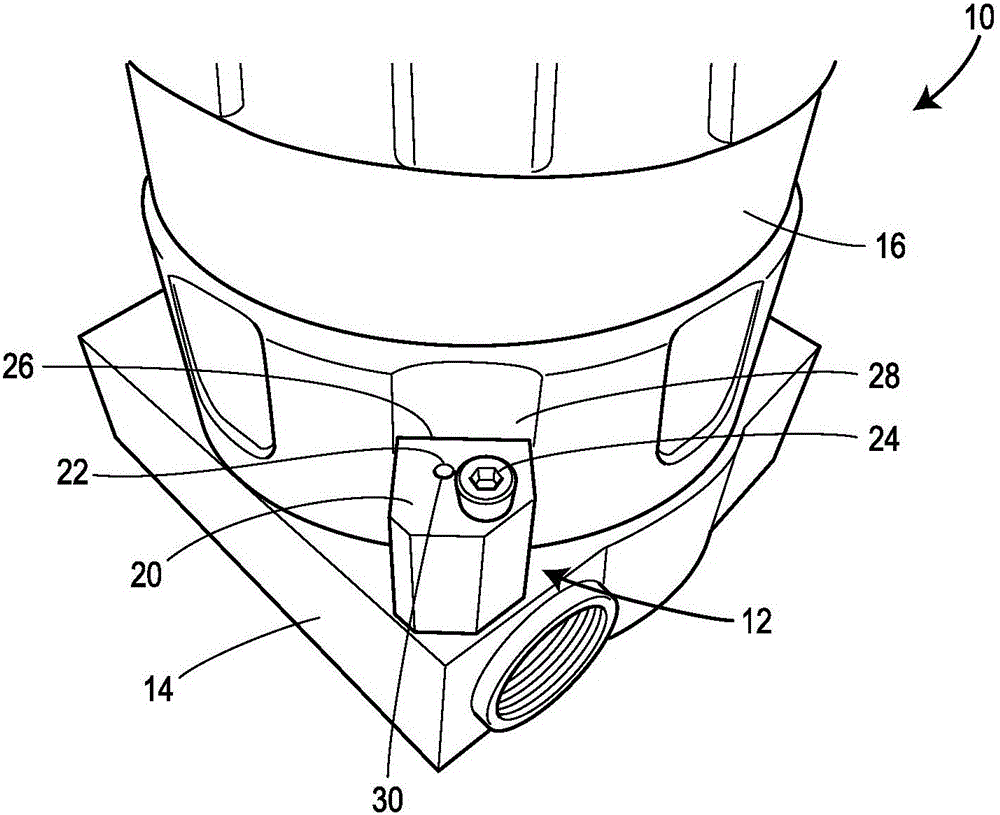

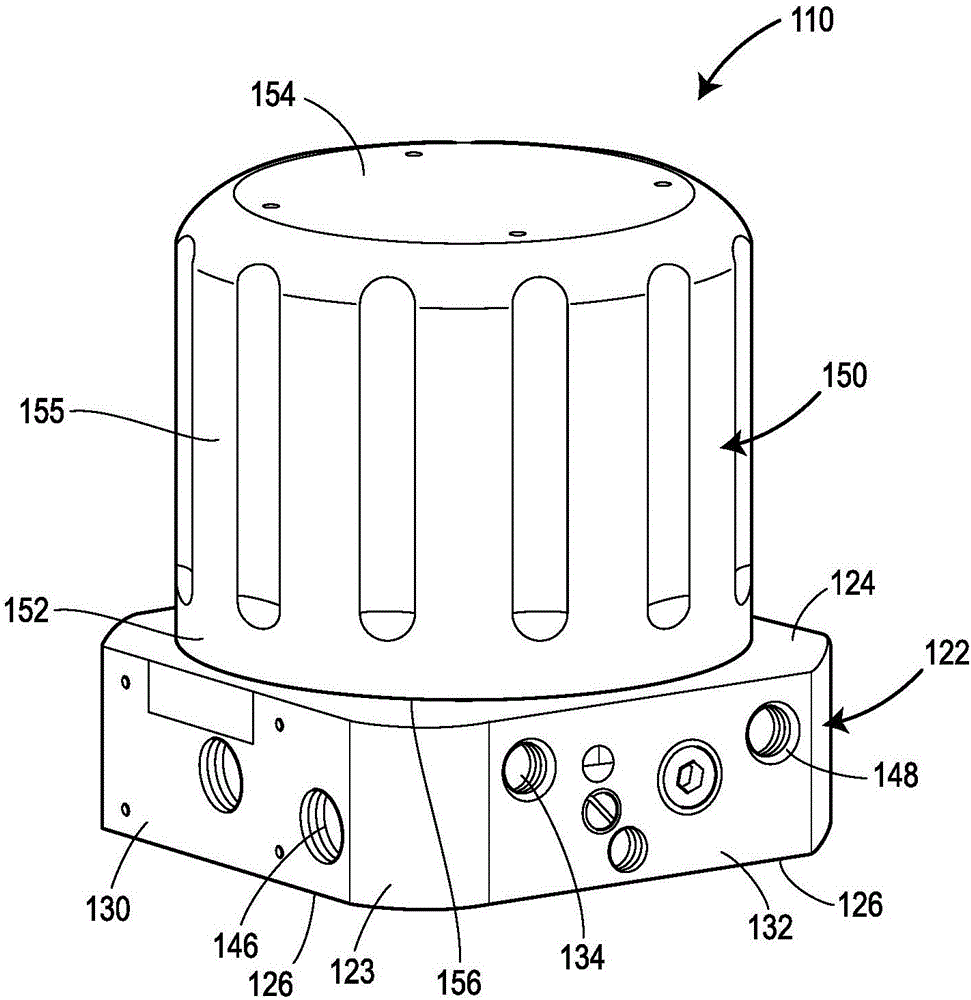

[0025] In summary, a one-piece or one-piece locking mechanism for a cover of an electro-pneumatic controller for use with a regulator is disclosed. The electro-pneumatic controller includes a base having a body, a top surface, and an aperture formed in the body. The one-piece locking mechanism is disposed within the bore of the base and includes a top surface that is flush with the top surface of the base. A cover is coupled to the base and includes an open end having a rim. The edge contacts a portion of the top surface of the locking mechanism and the top surface of the base. With a single tool such as an Allen wrench (Allen wrench), the locking mechanism is turned upwards in a counterclockwise direction to lock the cover to the base.

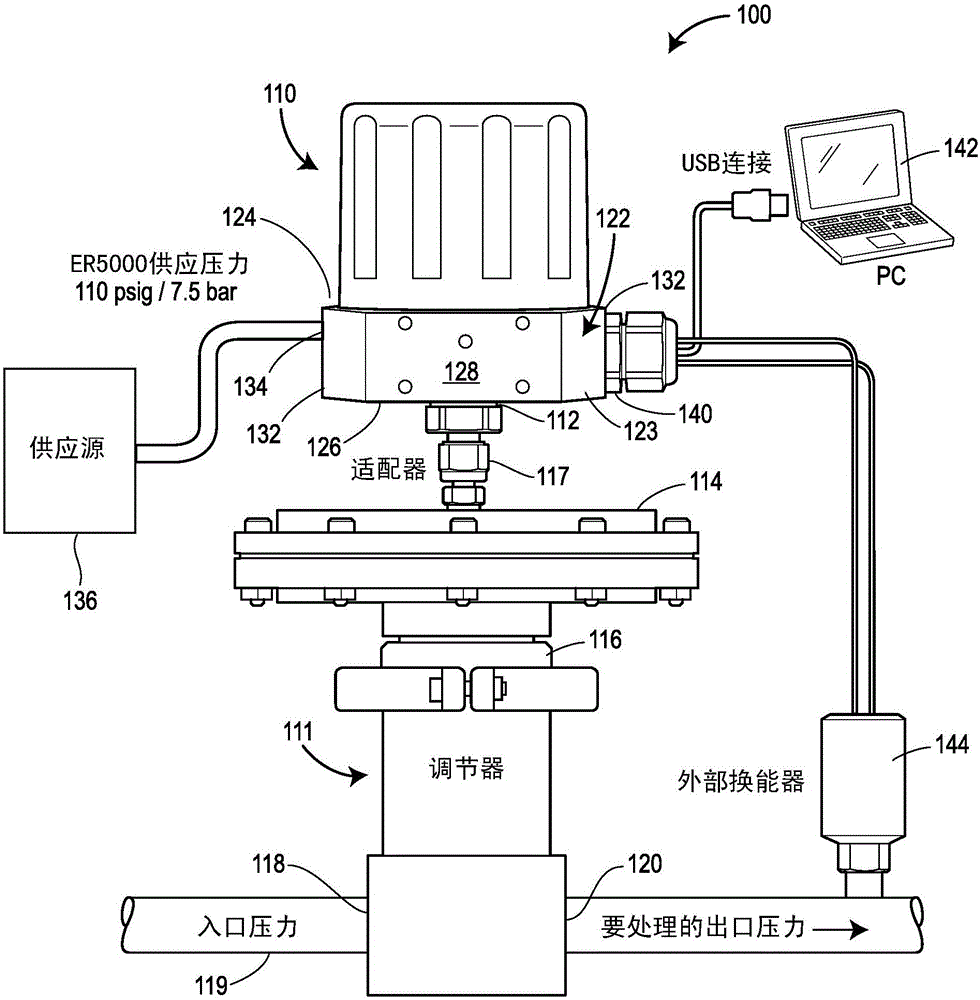

[0026] see now figure 2 , the process control system 100 includes an electro-pneumatic controller 110 operatively coupled to a regulator 111 . In particular, outlet port 112 of electro-pneumatic controller 110 is operatively coupled to t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com