An Image Measurement Method for Evaluating Pitting Corrosion Behavior of Tubing

A technology of image measurement and oil pipe, applied in the field of metal pitting corrosion evaluation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

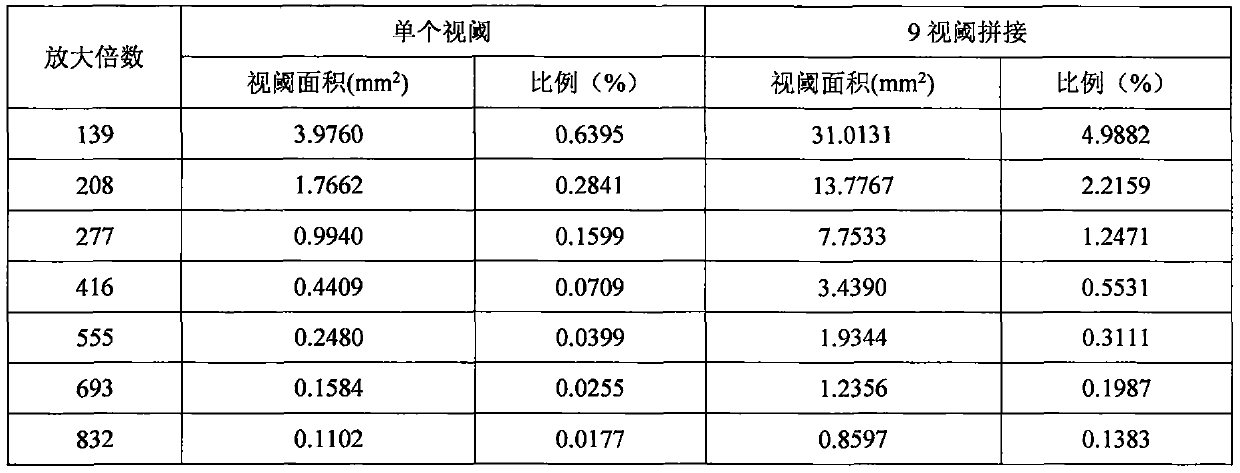

[0024] Measuring area corresponding to different magnifications

[0025] The material of the test piece used is J55 steel, the specification is 50×13×1.5mm, φ=6mm, and the surface area of the front and back of the test piece is 621.7265mm 2 , the microscope is an OLYMPUS DSX500 optical digital microscope, and the same area of the test piece is scanned with a single threshold of different magnifications and a 9-threshold mosaic scan (overlapping ratio of 10%). The results are shown in Table 1. Carry out splicing scanning of four points on one surface of the test piece with a magnification of 139 times and 9 visual thresholds, and the scanned area accounts for about 20% of the surface area, which is far beyond the research scope of other methods and can respond to the test more comprehensively and accurately. Pitting behavior on the chip surface.

[0026] Table 1 The scanning area corresponding to different magnifications and the proportion of the coupon surface

[0027] ...

Embodiment 2

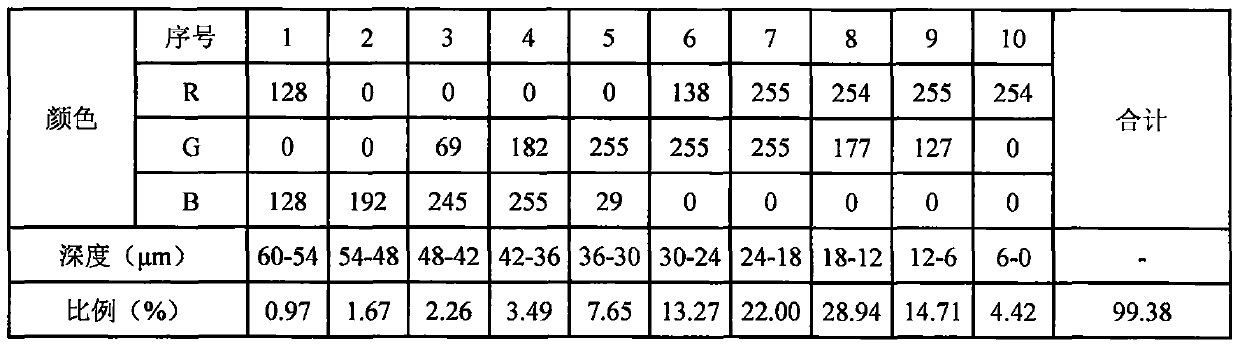

[0029] Test piece surface corrosion depth measurement

[0030] The material of the test piece used is J55 steel, the specification is 50×13×1.5mm, φ=6mm, the microscope is OLYMPUSDSX500 optical digital microscope, the magnification is 208 times, and the image is a single-vision threshold image. The 10 colors in the picture represent different corrosion depths. Set the ten colors to divide 0-60 μm into equal parts. From left to right, they represent the depths of 54-60 μm, 58-54 μm, and so on. The rightmost color represents the depth of 0-6 μm. . The maximum pitting depth in the picture was measured by a measuring microscope to be 59.32 μm, and the ratio of the area occupied by different colors to the visual threshold was analyzed by image analysis software to obtain the distribution of different corrosion depth ranges. The statistical results are shown in Table 2.

[0031] Table 2 Measurement results of corrosion depth on the surface of the test piece

[0032]

Embodiment 3

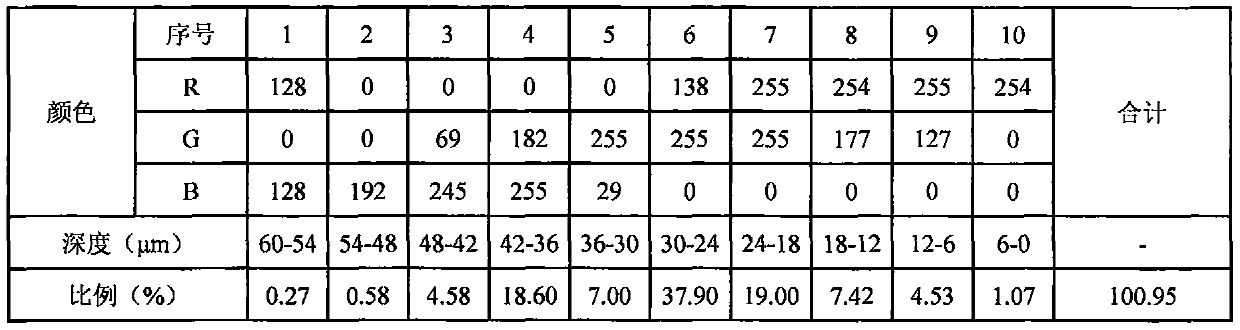

[0034] Pitting corrosion on the surface of the test piece

[0035] The material of the test piece used is J55 steel, the specification is 50×13×1.5mm, φ=6mm, corrosion conditions: 80g / L simulated formation water, 50°C, pressure 4MPa, corrosion time 5d. The microscope is an OLYMPUS DSX500 optical digital microscope with a magnification of 150 times. The image is a stitched image of 9 visual thresholds, and the depth represented by ten colors is 0-100 μm. The maximum pitting depth is 99.4μm, and the maximum pitting area is 64432μm 2 , see Table 3-Table 5 for the statistical results of corrosion information.

[0036] Table 3 Measurement results of corrosion depth on the surface of the test piece

[0037]

[0038] Table 4 Measurement results of area distribution of pitting pits on the surface of test pieces

[0039] Area (μm 2 )

0-50 50-100 100-150 150-200 200-250 250-300 300-350 350-400 400-450 450-500 >500 Proportion(%) 76.78 15.46 4.20 1.7...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com