Rice cooker and cover body assembly applied to rice cooker

A technology for cooking utensils and lids, which is applied to cooking utensil lids, applications, cooking utensils, etc., which can solve the problems of low assembly efficiency, inconvenient use, and easy loss, and achieve the effect of high assembly efficiency and not easy to lose

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

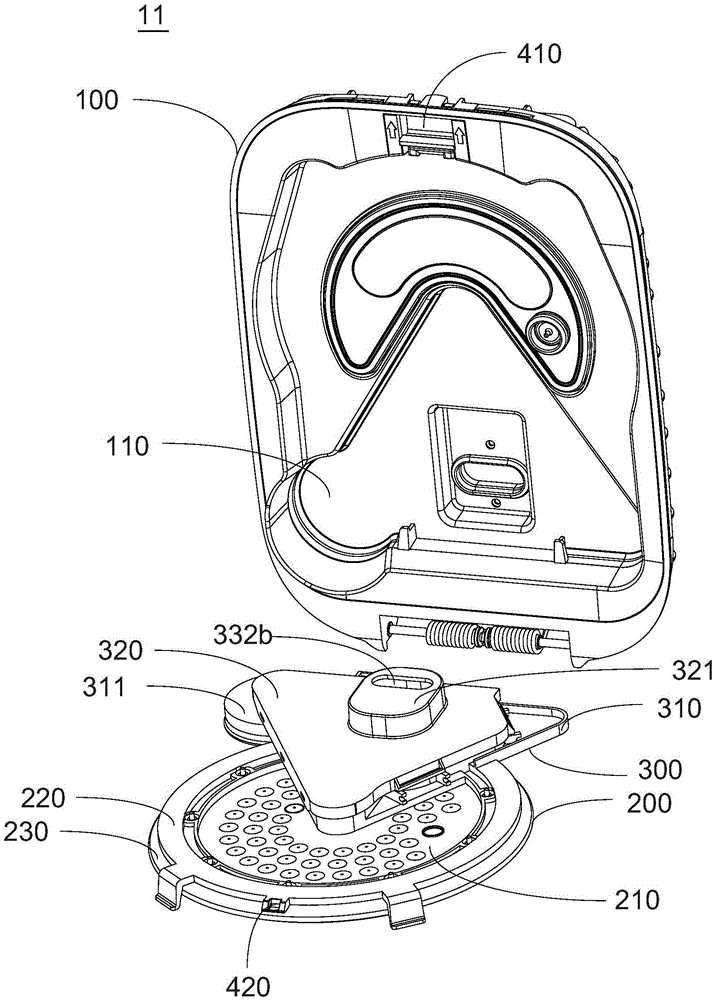

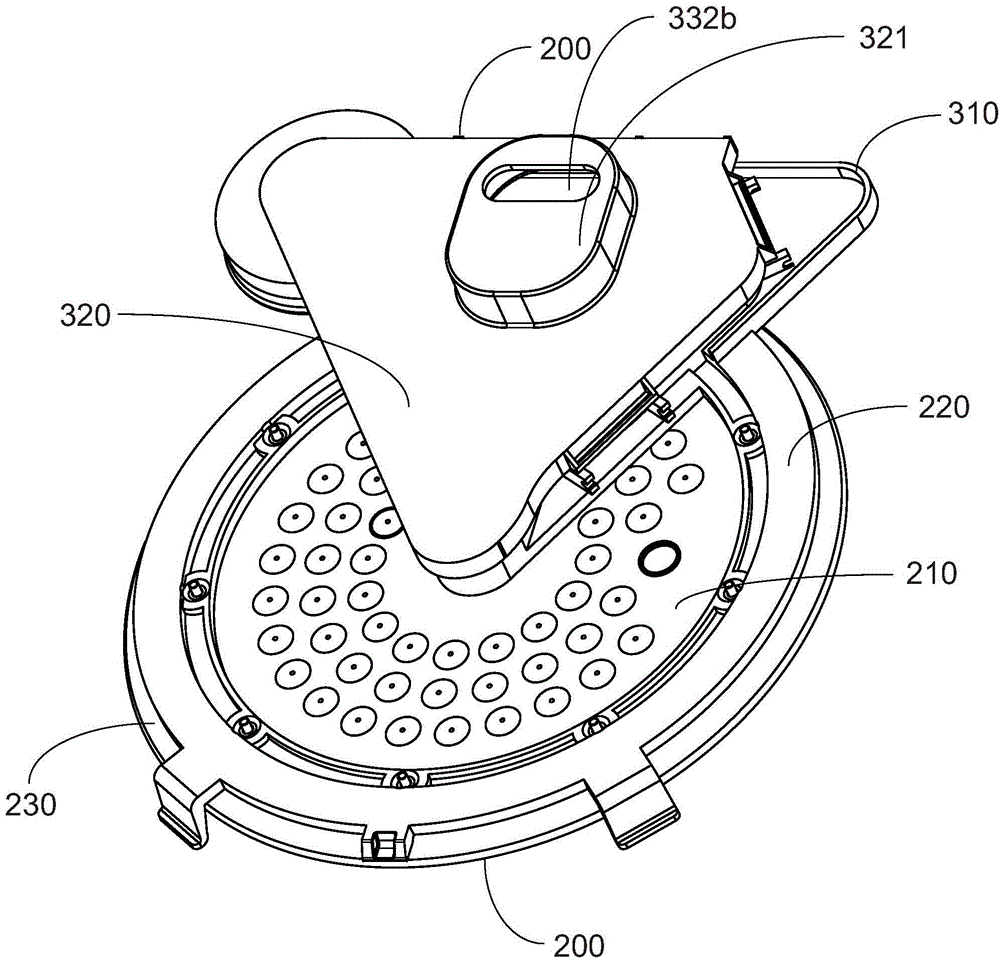

[0049] Below, refer to Figure 1 to Figure 4 A preferred embodiment of the present invention will be described. It can be understood that the rice cooker according to the present invention can be an electric rice cooker, an electric pressure cooker or other cooking utensils, and the rice cooker according to the present invention can also have various functions such as porridge cooking in addition to the function of cooking rice.

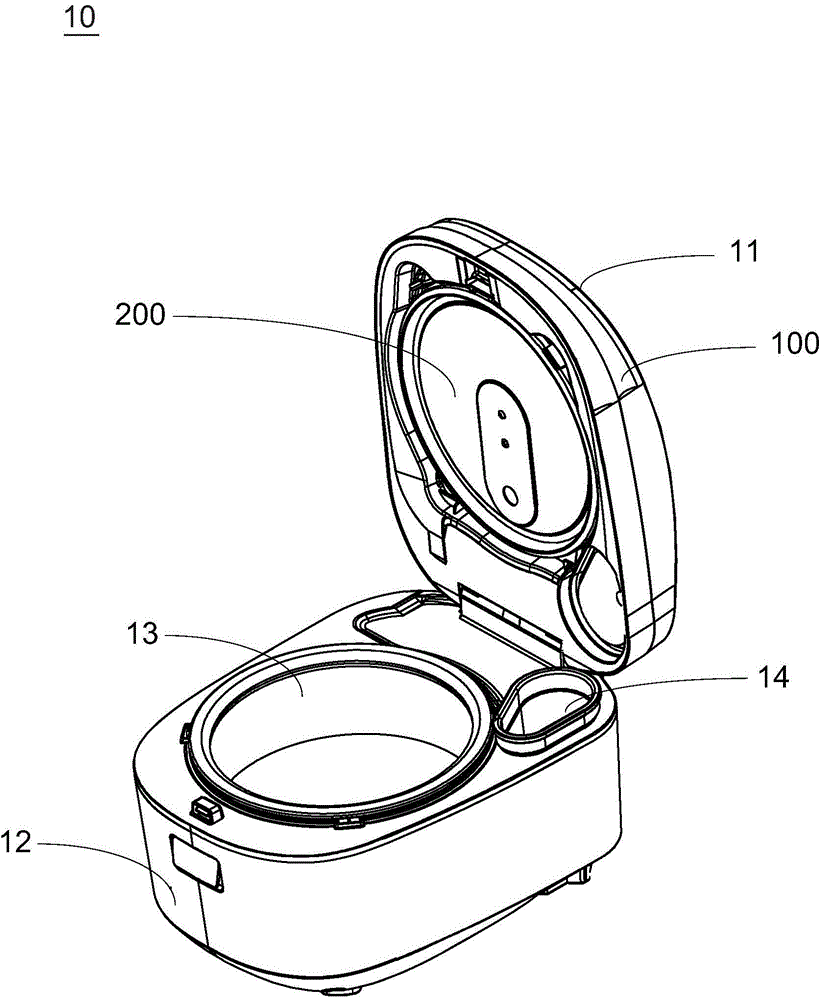

[0050] Such as figure 1 As shown, the rice cooker 10 includes a lid body assembly 11 (which will be described in detail below) and a pot body 12 . The pot body 12 is basically in the shape of a rectangular parallelepiped with rounded corners, and has a cylindrical inner pot accommodating cavity. The inner pot 13 can be freely put into the inner pot accommodating cavity or taken out from the inner pot accommodating cavity to facilitate the cleaning of the inner pot 13 . The inner pot 13 is generally made of metal material and has a circular opening...

Embodiment approach 2

[0086] Refer to the following Figure 5 Another preferred embodiment of the present invention will be described. For the purpose of simplification, when describing the second embodiment, the description of the same parts as those of the first embodiment is omitted.

[0087] Figure 5 is a schematic diagram according to the second preferred embodiment of the present invention. Such as Figure 5 As shown, the difference between Embodiment 2 and Embodiment 1 is that the steam channel member does not include a separate upper case, and the bottom surface 8320 of the recessed portion 8110 of the cover 8100 actually forms a part of the steam channel member (equivalent to the upper case Body), together with the lower casing 8310, forms a steam channel. In this embodiment, the part corresponding to the upper casing of the steam channel member is arranged on the cover body 8100, and the lower casing 8310 is arranged on the detachable cover part 8200 (as described above), so that onl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com