Multi-track and multi-measurement-position parallel testing and sorting device for integrated circuit chips

A sorting device and integrated circuit technology, applied in sorting and other directions, can solve the problems of scattered IC chip packaging and low efficiency, and achieve the effects of compact structure, improved efficiency, and automatic control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

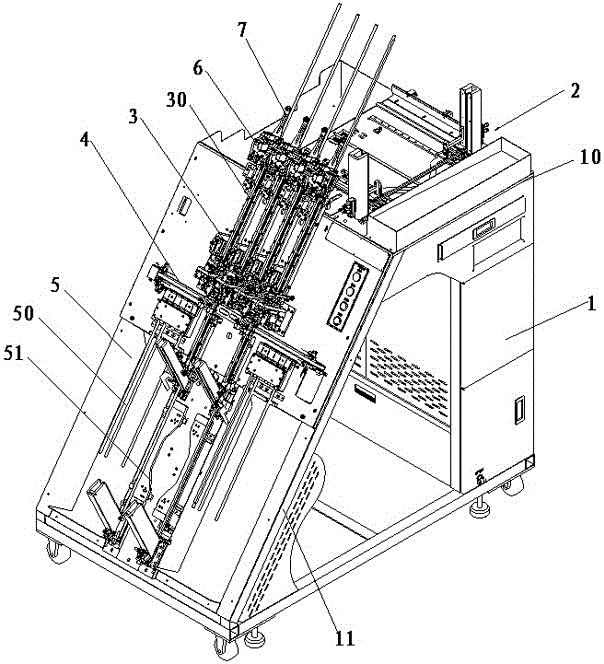

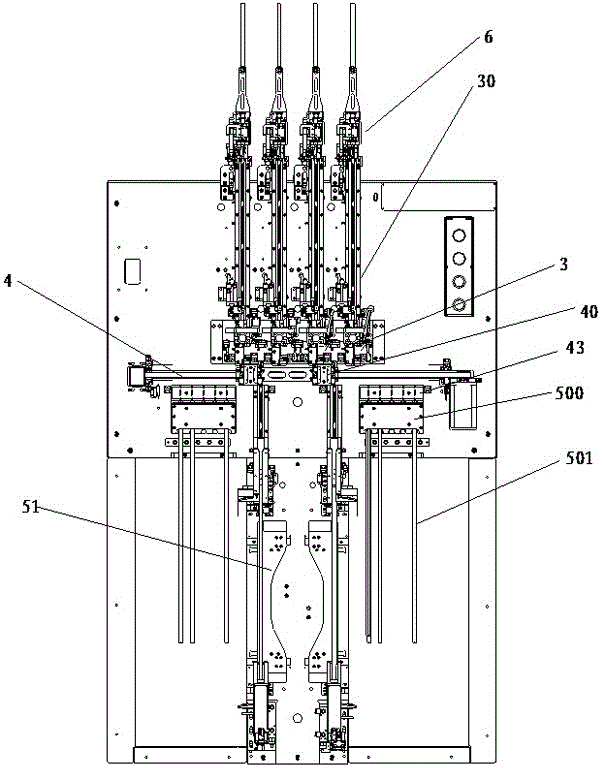

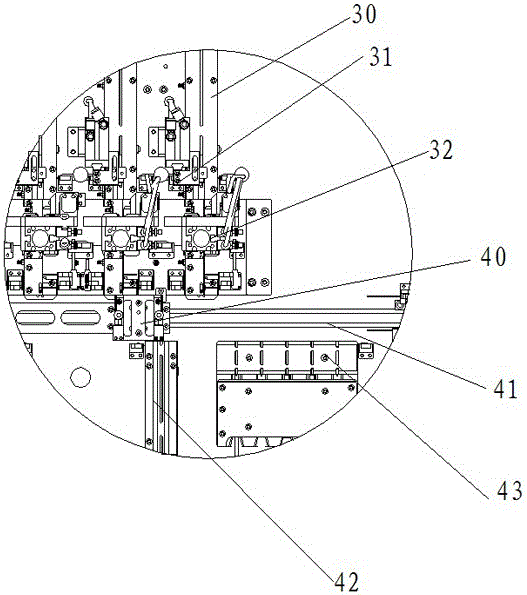

[0023] like Figure 1~6As shown, the embodiment of the present invention provides a multi-track multi-positioning parallel testing and sorting device for integrated circuit chips, including a frame 1, the upper surface of the frame 1 is provided with a flat plate for supporting the feeding mechanism 2, The front side of the frame 1 is provided with an inclined panel 11, and the inclined panel 11 is sequentially provided with a feeding test mechanism 3, a sorting buffer mechanism 4 and a receiving mechanism 5 from top to bottom; It includes 2N feeding track grooves 30 arranged at the upper end of the inclined plate 11 at uniform intervals along the lateral direction; each feeding track groove 30 entrance is respectively equipped with a lifting tube turning mechanism 6 that cooperates with the feeding mechanism 2, and the feeding A first infrare...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap