Unblocked long roller claw lathe center rest

A column claw frame and center frame technology, applied in the field of smooth long roller claw lathe center frame, can solve the problems of unbalanced force application, low production efficiency, and continuous turning processing, etc., to improve turning quality, High working efficiency and increased rigidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] It should be noted that, in the case of no conflict, the embodiments of the present invention and the features in the embodiments can be combined with each other.

[0015] The present invention will be described in detail below with reference to the accompanying drawings and examples.

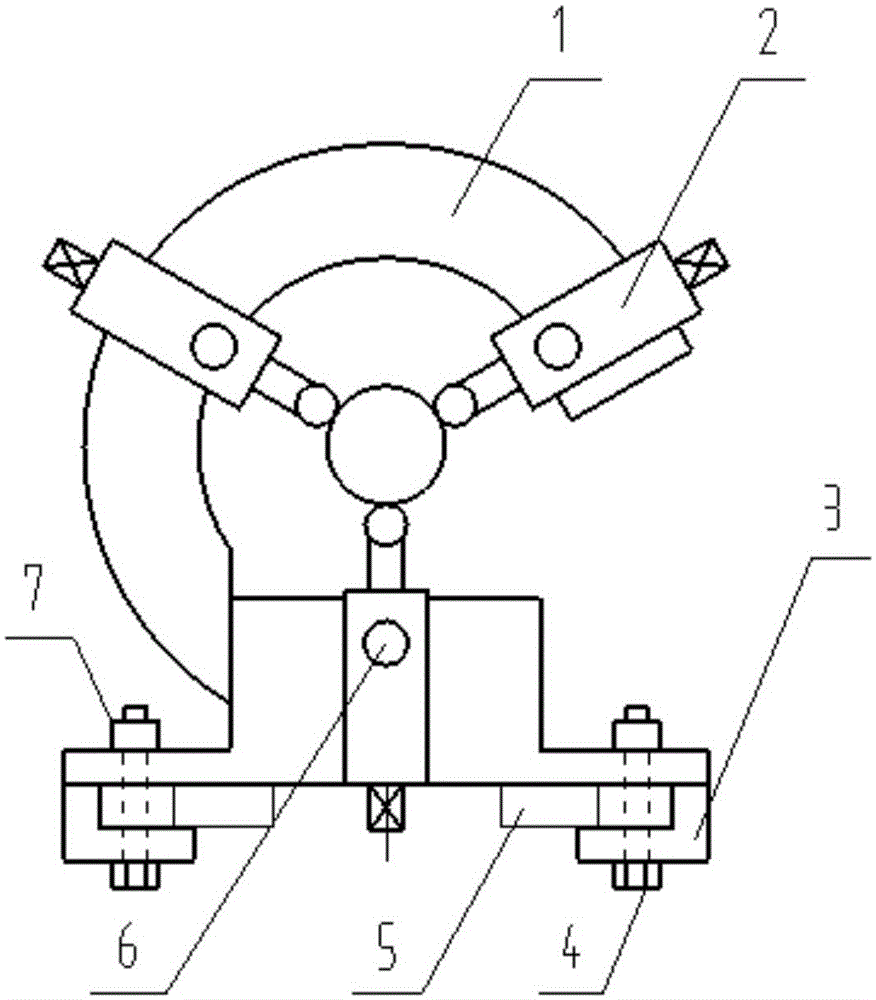

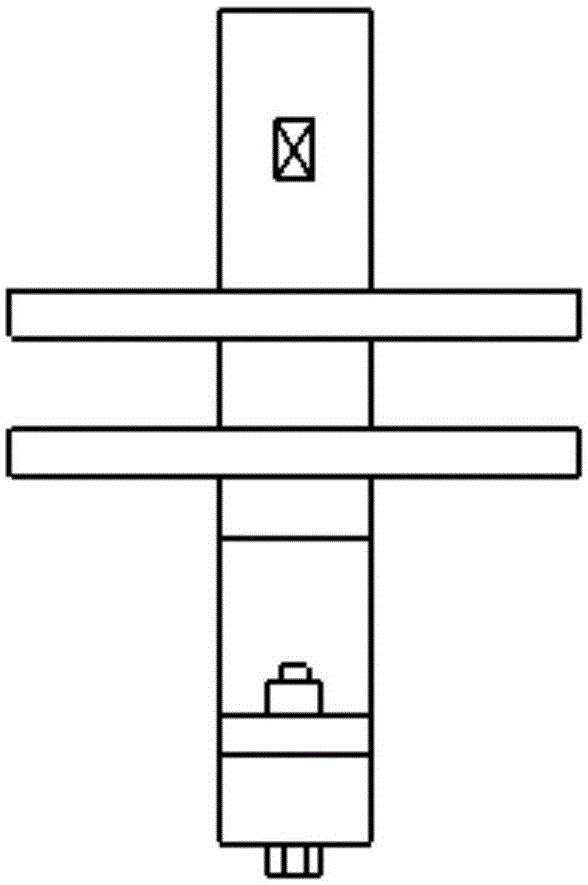

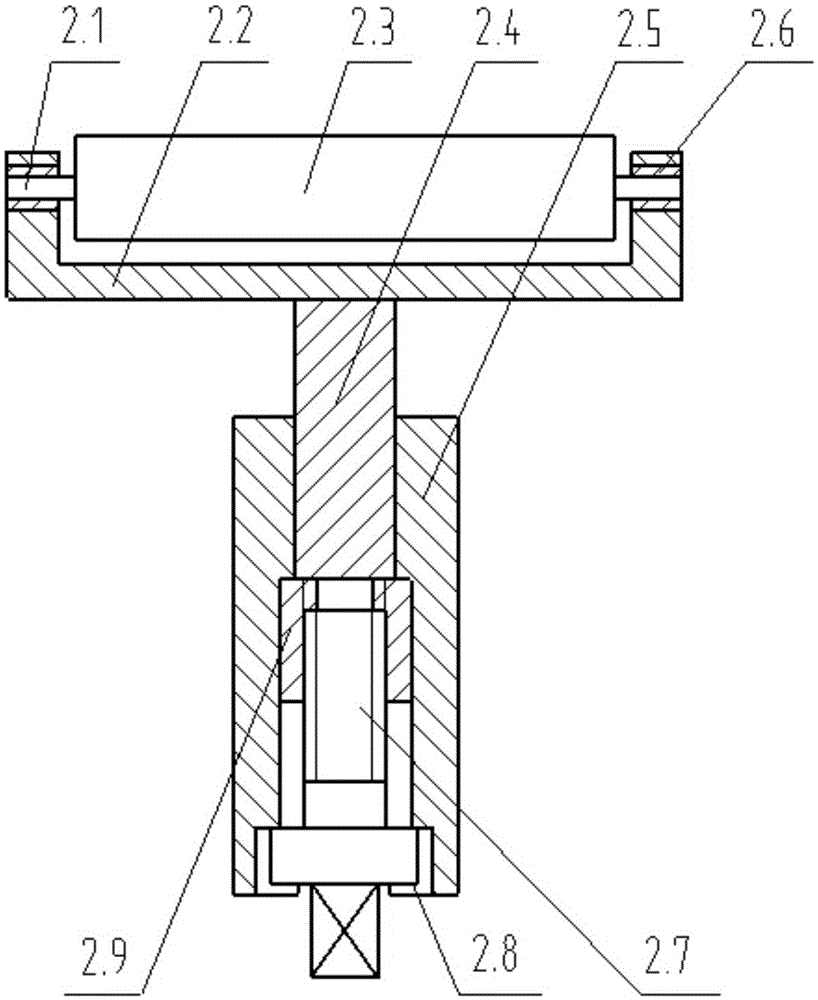

[0016] According to the present invention, a smooth type long roller claw lathe center frame, as shown in the accompanying drawings, it consists of a center frame body 1, a long roller claw mechanism 2, a long roller claw shaft 2.1, a long roller Jaw frame 2.2, long roller jaw 2.3, long roller jaw frame body 2.4, long roller jaw frame body cover 2.5, long roller jaw bearing 2.6, adjustment screw 2.7, pressure ring 2.8, adjustment block 2.9 , Press plate 3, press plate screw 4, lathe guide rail 5, claw locking screw 6, press plate nut 7. The center frame frame body 1 is an open frame body that ensures sufficient rigidity and opens to the direction of the lathe tool rest, and is connected...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com