Accurate oil distribution hydraulic steering device

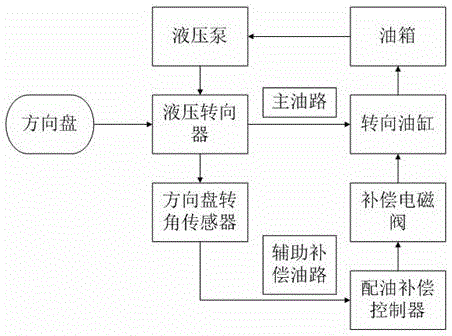

A hydraulic steering gear and precise technology, applied in the direction of the fluid steering mechanism, etc., can solve the problems of affecting the control accuracy of the steering system, the inability to correspond to the position of the steering wheel in the steering wheel rotation state, and potential safety hazards, and achieve precise control, steering sensitivity, and precise matching. oil effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be described in further detail below in conjunction with the accompanying drawings.

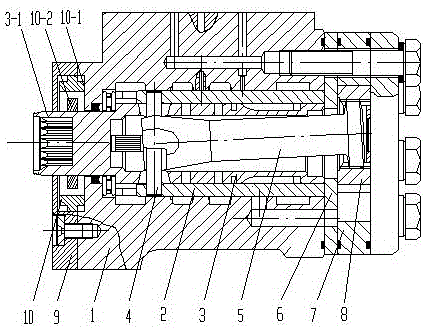

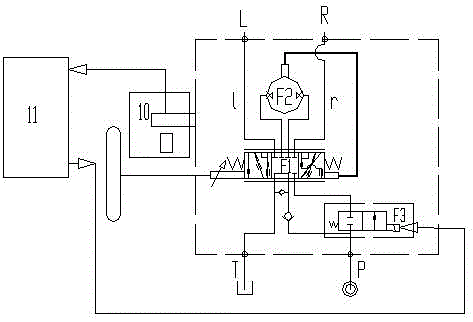

[0016] The basic structure of the precise oil distribution hydraulic steering gear of this embodiment is as follows: figure 1 and figure 2 As shown, the housing 1 has an oil inlet P and left and right oil delivery ports L and R respectively connected to both ends of the steering hydraulic cylinder (not shown in the figure). There is a valve sleeve 2, and the valve sleeve 2 is equipped with a valve core 3 extending out of the steering input shaft 3-1 to form a distribution valve assembly F1. The end of steering input shaft 3-1 is connected with steering wheel by spline. One end of the inner hole of the valve core 3 is fitted with a linkage shaft 5 that forms a circumferential constraint with the valve sleeve 2 through a radial pin 4, and the other end of the housing 1 is fixedly connected with the stator 7 of the cycloidal pinwheel pair F2 through a spacer ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com