Heavy-load carrying manipulator for forging

A technology for manipulators and forgings. It is applied in the field of heavy-duty handling manipulators for forging. It can solve the problems that cannot meet the requirements of control accuracy and rapidity, and achieve the effect of increasing the overall structural strength and satisfying the accuracy and rapidity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

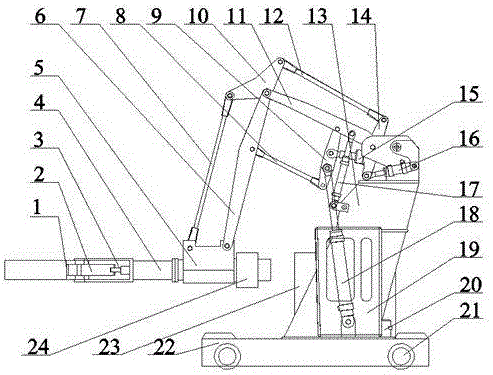

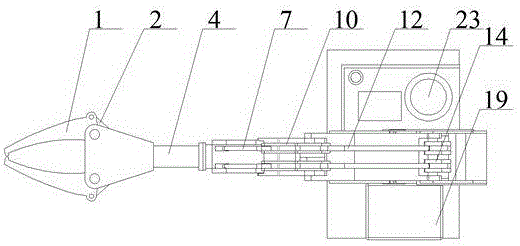

[0016] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0017] As shown in the figure, a heavy-duty handling manipulator for forging includes a traveling mechanism, a displacement adjustment mechanism, a clamping mechanism, and a power mechanism 24 for driving the clamping mechanism. The clamping mechanism is set on the traveling mechanism through the displacement adjustment mechanism and walks with it. The mechanism moves synchronously, and the clamping mechanism is driven by the displacement adjustment mechanism to realize the movement in the horizontal direction and the vertical direction. , the support frame 5 is provided with a sleeve, and the clamping cylinder 3 is located in the sleeve, and its cylinder rod is connected to the clamp 1 through the pull rod 2, and the end of the sleeve away from the clamp 1 is connected to the power mechanism for driving the clamp 1. twenty four.

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com