A paper feeding system for a printing machine

A printing machine and paper feeding technology, which is applied in the field of paper feeding system, can solve problems such as failure to achieve constant temperature and humidity, affect work efficiency, and printing machine failure, and achieve the effects of improving printing efficiency, eliminating static electricity, and saving costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The technical solutions of the present invention will be further described and illustrated through specific examples below.

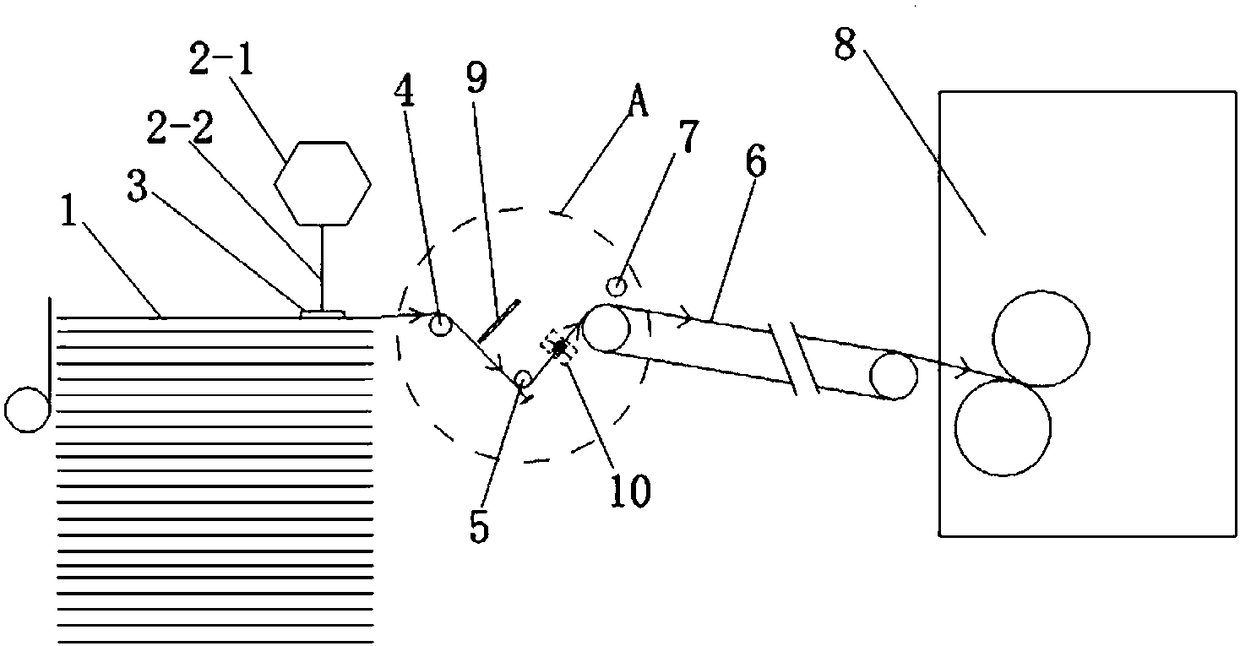

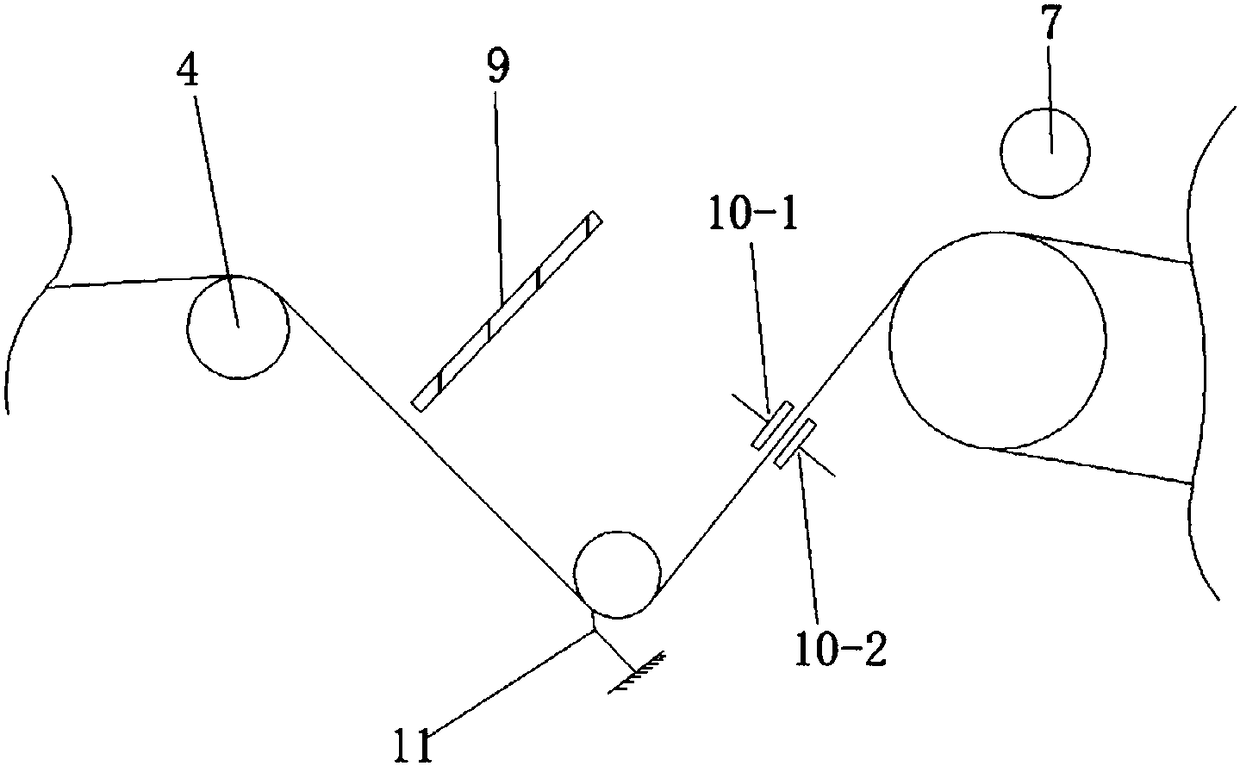

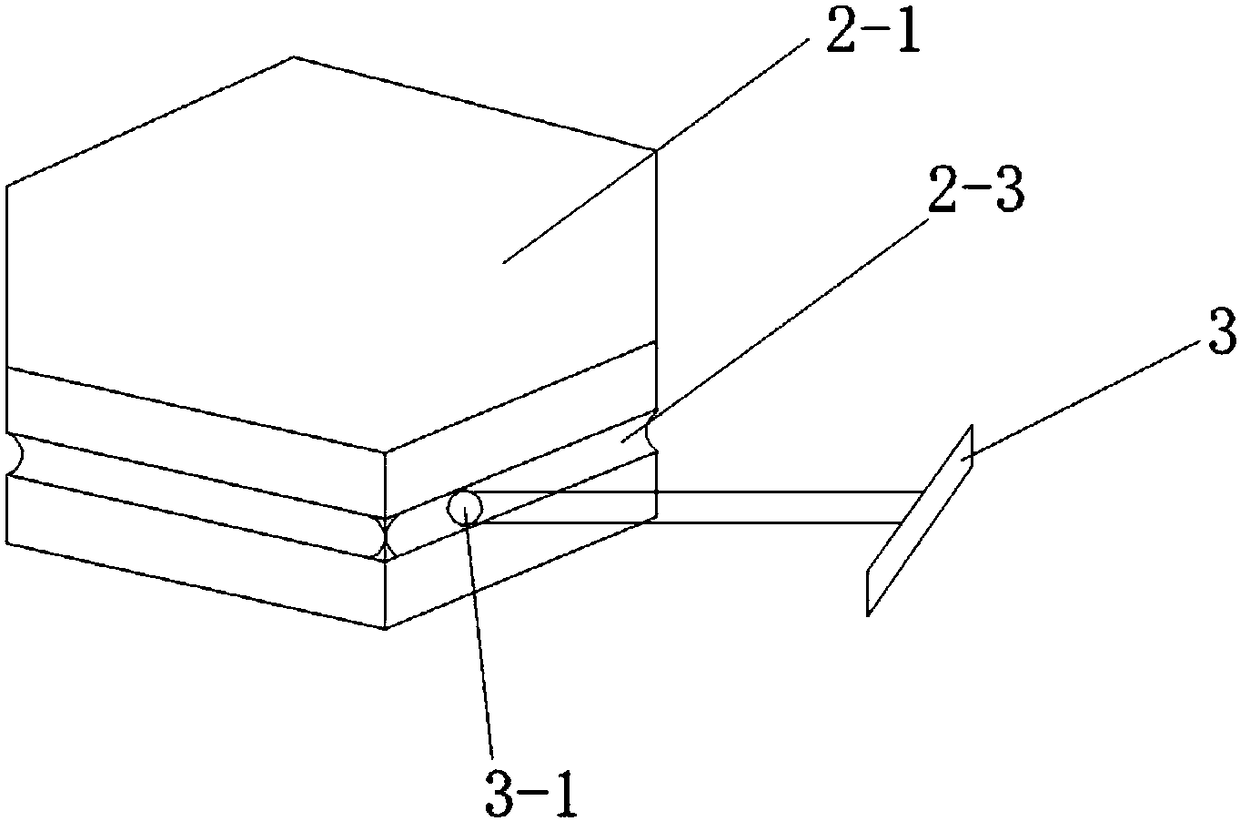

[0023] like Figure 1-3 As shown, the paper feeding system of the printing machine in this embodiment includes a paper separation assembly, a first guide roller 4 , a second guide roller 5 , an ultrasonic double sheet detection element 10 and a transmission assembly 6 . The paper separation assembly includes a suction nozzle 3, a driving mechanism 2 and a vacuum pump. The suction nozzle 3 is connected to the vacuum pump through the air flow channel. The vacuum pump works through the suction nozzle 3 to have suction on the paper; the paper separation assembly needs to drive the paper 1 to the first guide roller 4 With the cooperation of the mechanism 2, the driving structure 2 includes a driving roller 2-1 with a hexagonal cross section and a connecting rod 2-2. The driving roller 2-1 is provided with a track groove 2-3, and one end of the connect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com