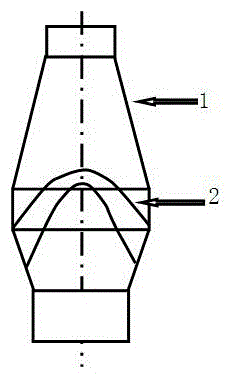

Method for reducing material surface smog through stock level lowering and spraying in blast furnace

A technology of reducing material line and material surface, applied in blast furnace, blast furnace details, furnace and other directions, to achieve the effect of being conducive to construction, clear vision and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0012] Example 1 : a method for spraying and reducing the smog on the material surface of a blast furnace lowering line. The wind material is loaded into the blast furnace strictly according to the off-air material plan, which is not only beneficial to the construction, but also conducive to the resumption of production of the blast furnace. Dolomite is a compound salt of calcium carbonate and magnesium carbonate with the molecular formula CaMg(CO 3 ) 2 , the decomposition equations of pure calcium carbonate and magnesium carbonate are:

[0013] CaCO 3 = CaO + CO 2

[0014] MgCO 3 =MgO+ CO 2

[0015] The decomposition boiling temperature of pure calcium carbonate is 910°C, and the decomposition boiling temperature of pure magnesium carbonate is 640°C. And dolomite is a composite carbonate, MgCO with low decomposition temperature in the composite salt when heated 3 compared to CaCO 3 Decomposes first, MgCO between 700°C and 900°C 3 and CaCO 3 All disassembled. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com