A kind of preparation method of high-entropy alloy powder and high-hardness high-entropy alloy coating

A high-entropy alloy and high-hardness technology, which is applied in the coating process and coating of metal materials, can solve the problems of poor surface forming quality, failure to meet the requirements of special industry applications, and failure to improve the forming quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

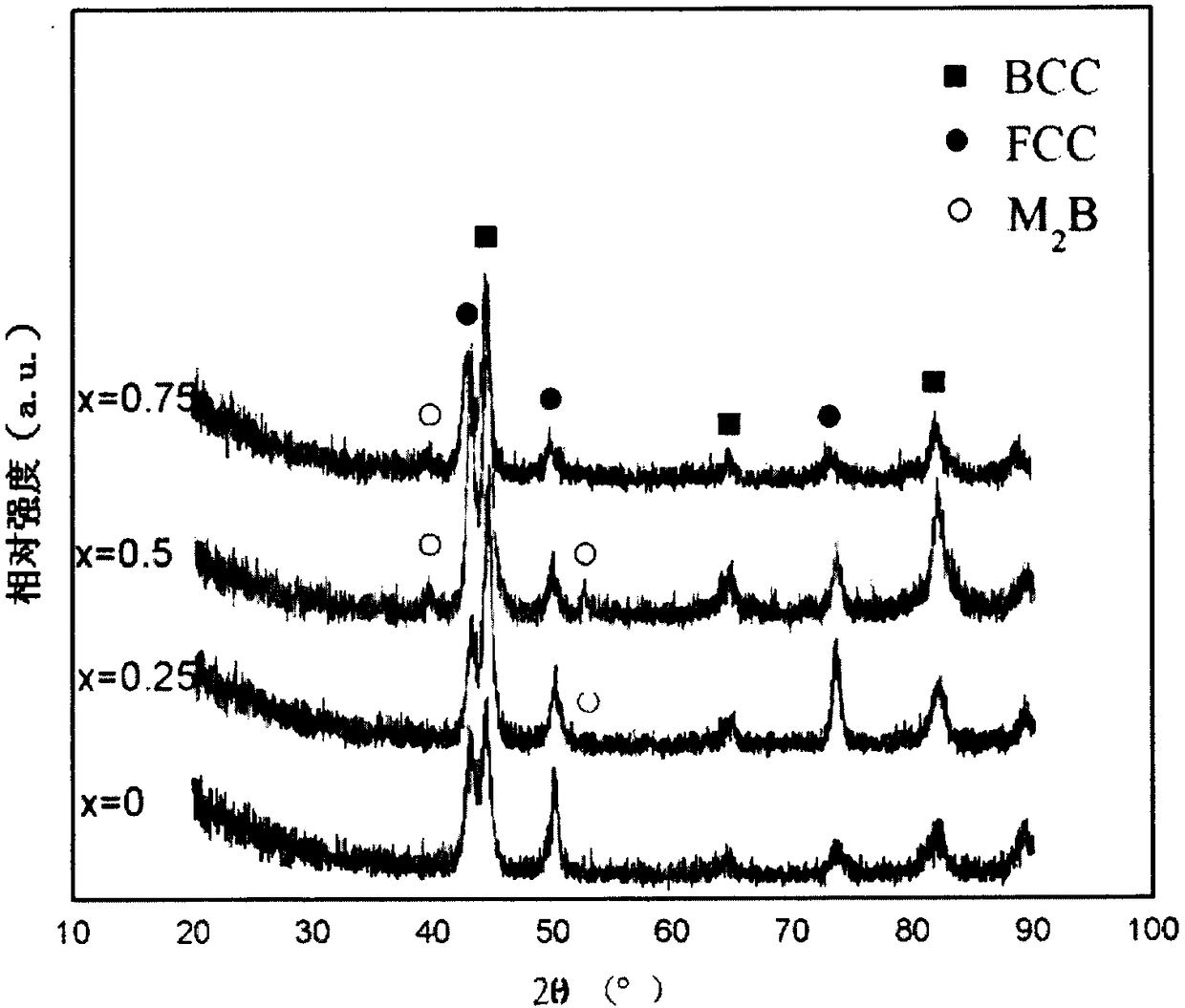

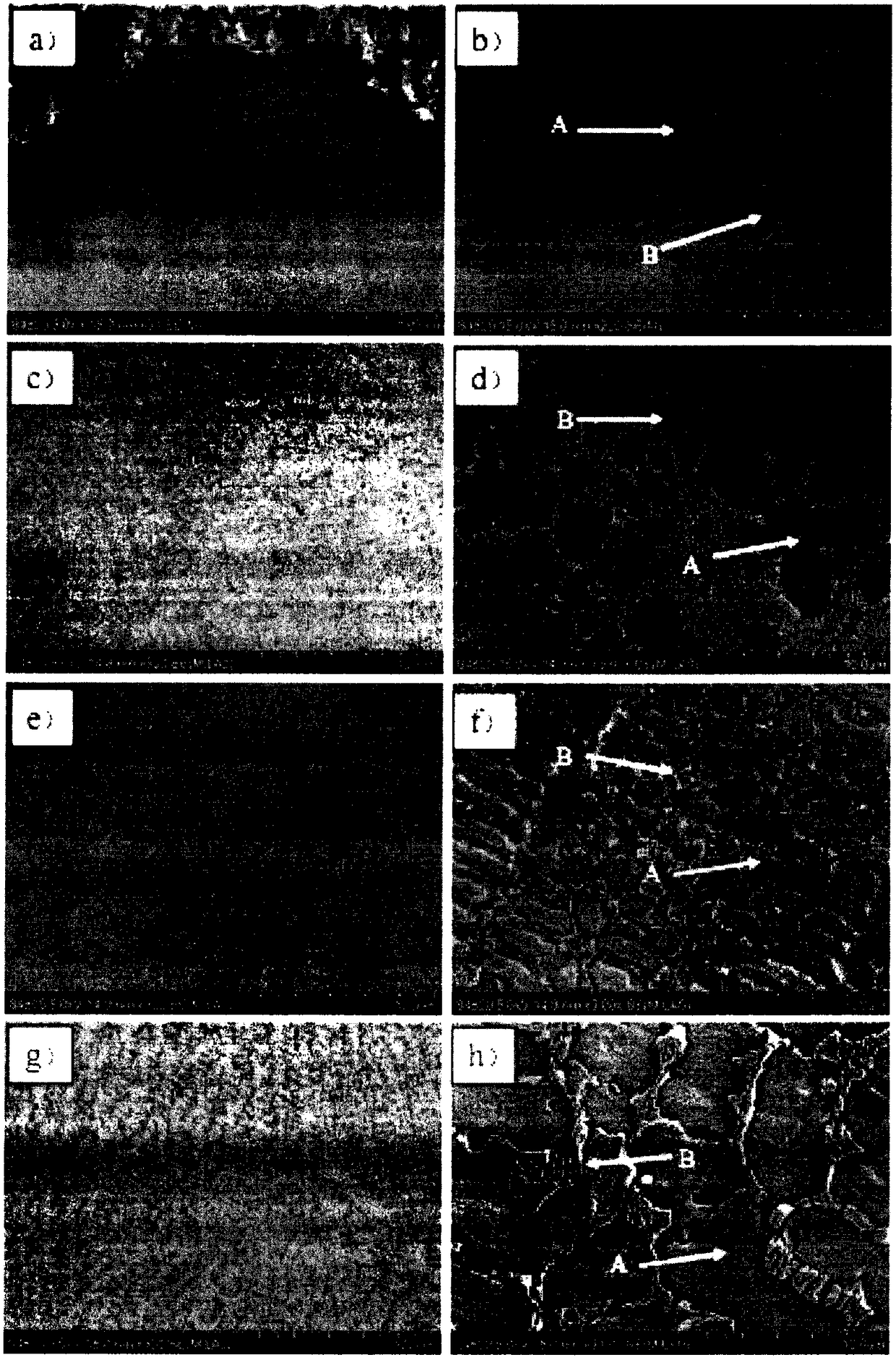

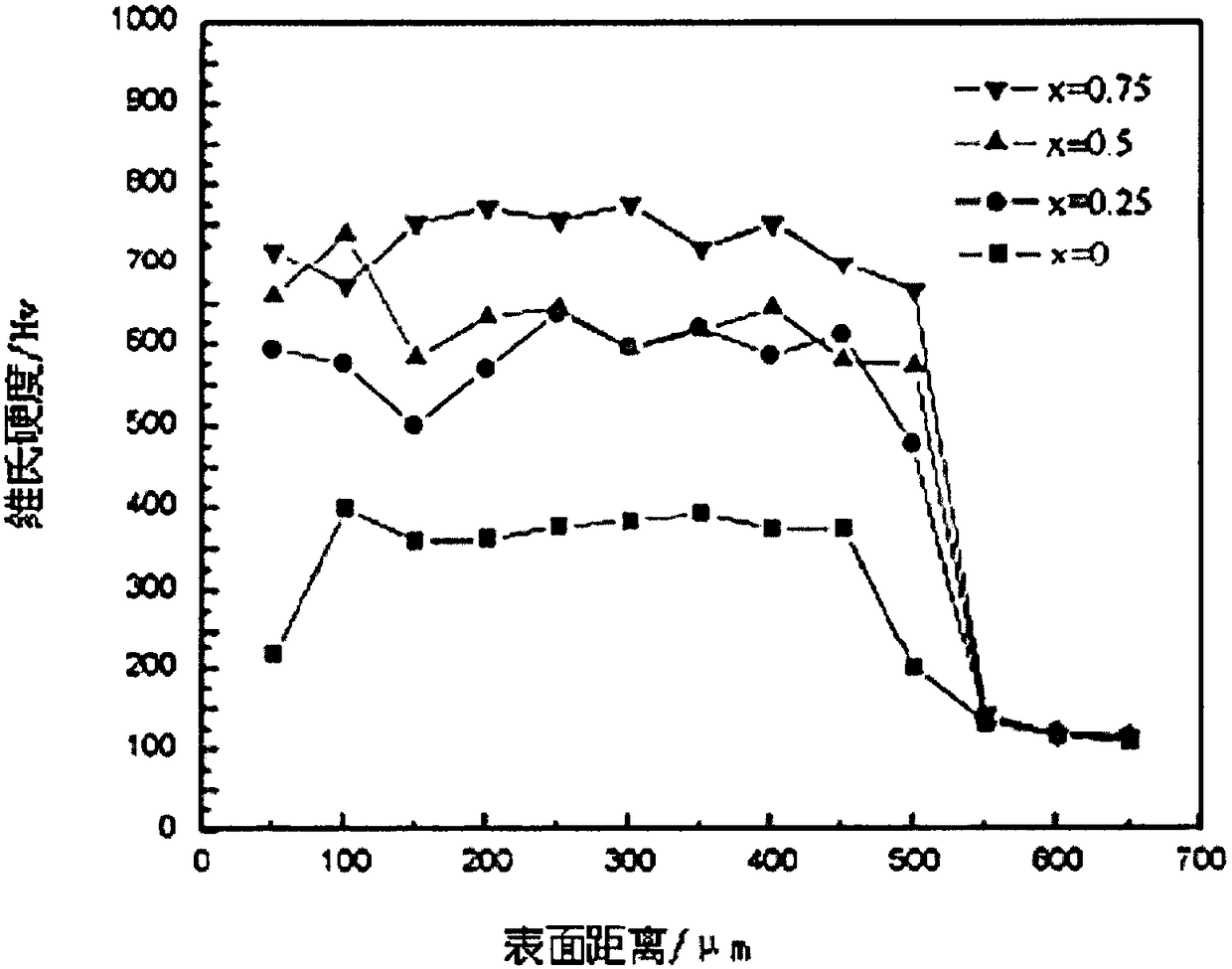

[0021] A method for preparing a high-hardness high-entropy alloy coating, comprising the following steps: mixing Fe, Ni, Al, Cr, Co, and B element powders with a purity higher than 99.9%, and performing ball milling at room temperature using a planetary ball mill, The ball-milled powder is pre-placed on the substrate with a pre-set thickness of 1.5mm. After the pre-coating is dried, multi-pass cladding is performed on a carbon dioxide high-power laser. The laser power used is 500W and the scanning speed is 3mm / s. The spot diameter is 4mm, and the inert gas argon is used for protection during cladding;

[0022] The Fe, Ni, Al, Cr, and Co element powders in the step A are equimolar mixing, and the molar amount of the B element powder added is 75% of other elements, that is, the expression of the alloy is FeNiAlCrCoBx, x=0.75;

[0023] The milling time of the ball mill is 8 hours, the ball-to-material ratio (mass ratio) is 10:1, and the milling speed is 200 r / min.

Embodiment 2

[0025] A method for preparing a high-hardness high-entropy alloy coating, comprising the following steps: mixing Fe, Ni, Al, Cr, Co, and B element powders with a purity higher than 99.9%, and performing ball milling at room temperature using a planetary ball mill, The ball-milled powder is pre-placed on the substrate with a pre-set thickness of 1.5mm. After the pre-coating is dried, multi-pass cladding is performed on a carbon dioxide high-power laser. The laser power used is 500W and the scanning speed is 3mm / s. The spot diameter is 4mm, and the inert gas argon is used for protection during cladding;

[0026] The Fe, Ni, Al, Cr, and Co element powders in the step A are equimolar mixing, and the molar amount of the B element powder added is 50% of other elements, that is, the expression of the alloy is FeNiAlCrCoBx, x=0.5;

[0027] The milling time of the ball mill is 8 hours, the ball-to-material ratio (mass ratio) is 10:1, and the milling speed is 200 r / min.

Embodiment 3

[0029] A method for preparing a high-hardness high-entropy alloy coating, comprising the following steps: mixing Fe, Ni, Al, Cr, Co, and B element powders with a purity higher than 99.9%, and performing ball milling at room temperature using a planetary ball mill, The ball-milled powder is pre-placed on the substrate with a pre-set thickness of 1.5mm. After the pre-coating is dried, multi-pass cladding is performed on a carbon dioxide high-power laser. The laser power used is 500W and the scanning speed is 3mm / s. The spot diameter is 4mm, and the inert gas argon is used for protection during cladding;

[0030] The Fe, Ni, Al, Cr, and Co element powders in the step A are equimolar mixing, and the molar amount of the B element powder added is 25% of other elements, that is, the expression of the alloy is FeNiAlCrCoBx, x=0.25;

[0031] The milling time of the ball mill is 8 hours, the ball-to-material ratio (mass ratio) is 10:1, and the milling speed is 200 r / min.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Vickers hardness | aaaaa | aaaaa |

| Vickers hardness | aaaaa | aaaaa |

| Vickers hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com