A kind of oil pumping unit using power assembly for counterweight

A technology of power assembly and counterweight, which is applied in the direction of machines/engines, mechanical equipment, liquid variable displacement machinery, etc., can solve the problems of increasing the manufacturing cost of pumping units, transportation, installation and maintenance difficulties, and beam pumping units Problems such as heavy weight, achieve significant beneficial effects, save raw materials, and be suitable for application and promotion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

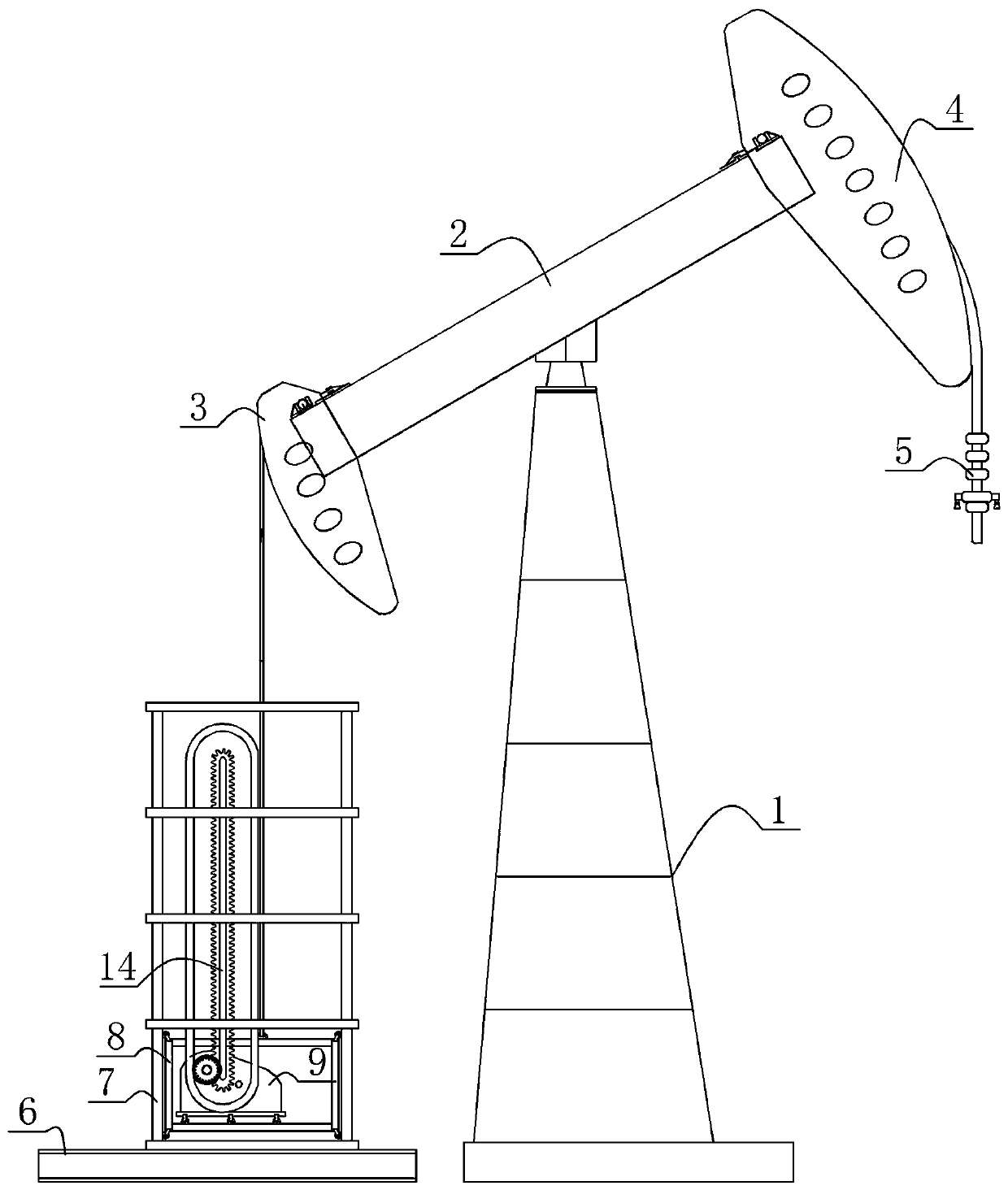

[0018] Such as figure 1 As shown, the structure schematic diagram of the oil pumping unit utilizing the power assembly to carry out the counterweight of the present invention is provided, which consists of a support 1, a beam 2, a counterweight donkey head 3, a fixing member 4 and a mechanism for driving the beam to reciprocate up and down. The driving mechanism consists of the middle part of the beam 2 shown hinged on the top of the bracket 1, the counterweight donkey head 3 fixed on the left end of the beam 2, and the fixing part 4 fixed on the right end of the beam 2. The sucker rod 5 is arranged on the fixing member 4 for realizing the oil pumping operation, and the driving mechanism is arranged at one end of the counterweight donkey head.

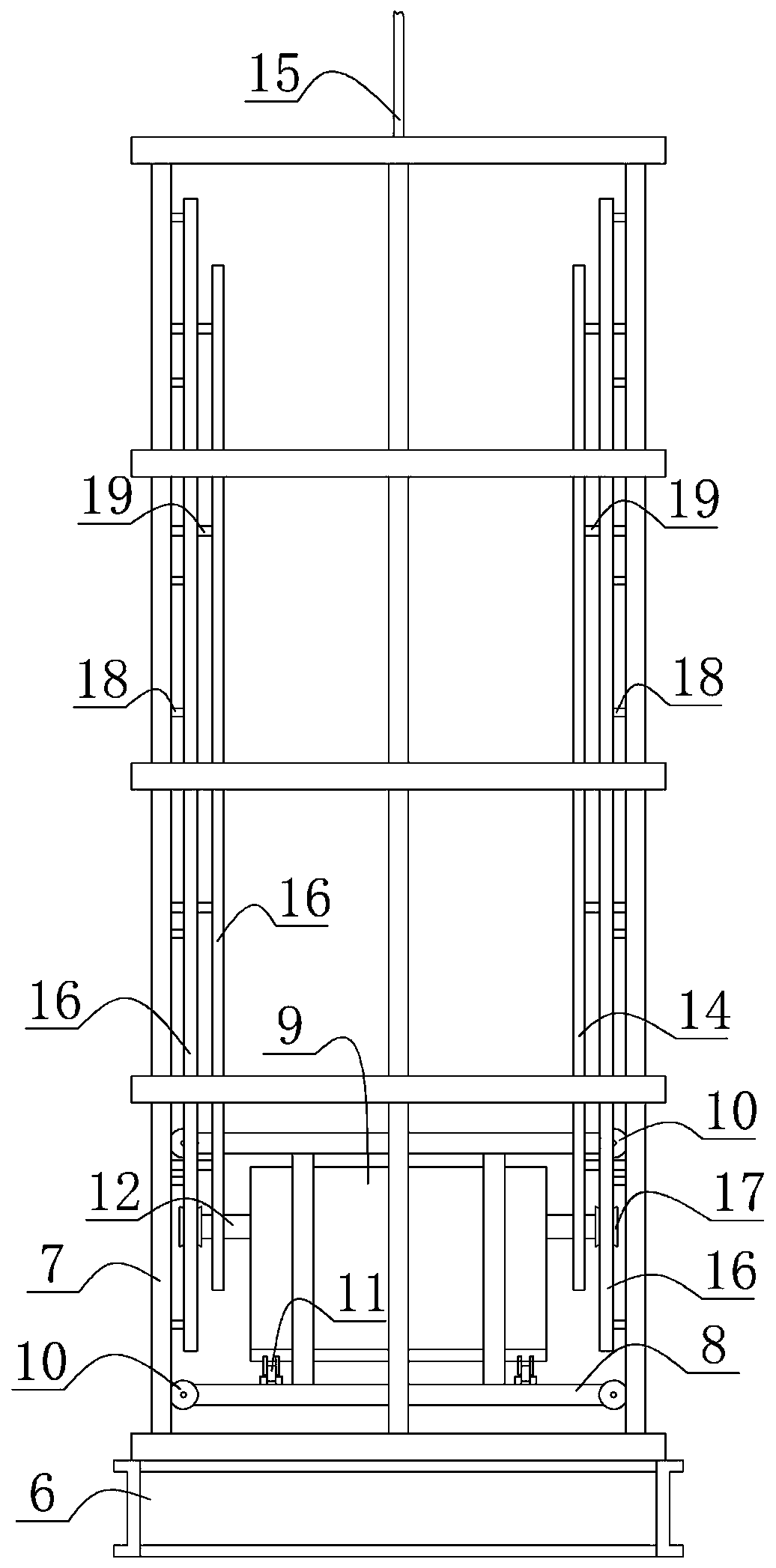

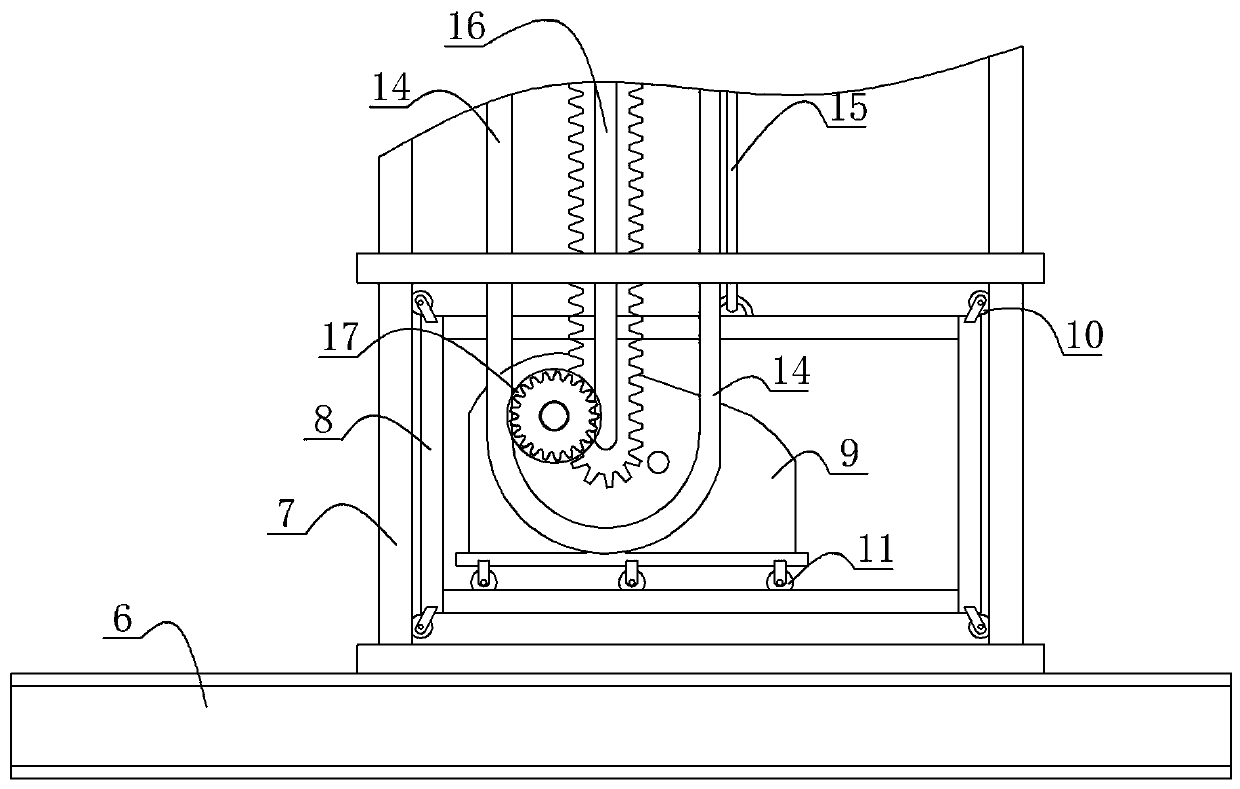

[0019] The driving mechanism shown is composed of an outer frame 7, an inner frame 8 and a power assembly 9,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com