Forced circulation water heater of engine

A water heater and forced circulation technology, applied in engine components, engine starting, machine/engine, etc., can solve problems such as inability to perform automatic monitoring, filter disassembly and cleaning, uncontrollable temperature, etc., to achieve compact structure, sealing The effect is good, the effect of improving the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

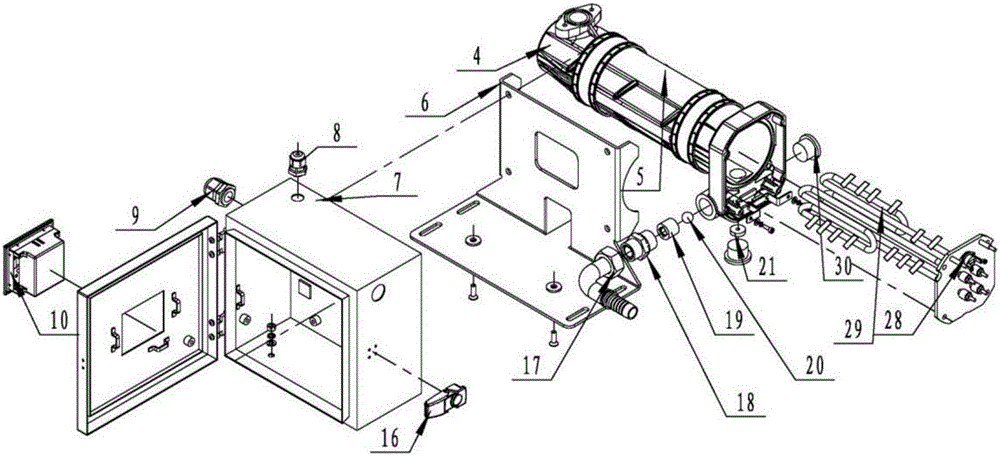

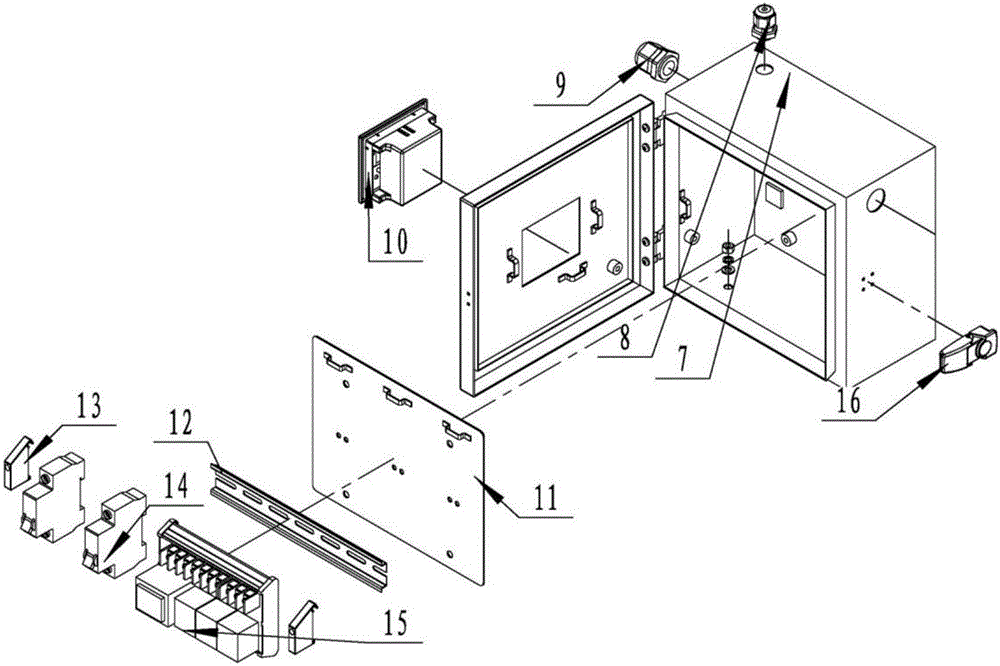

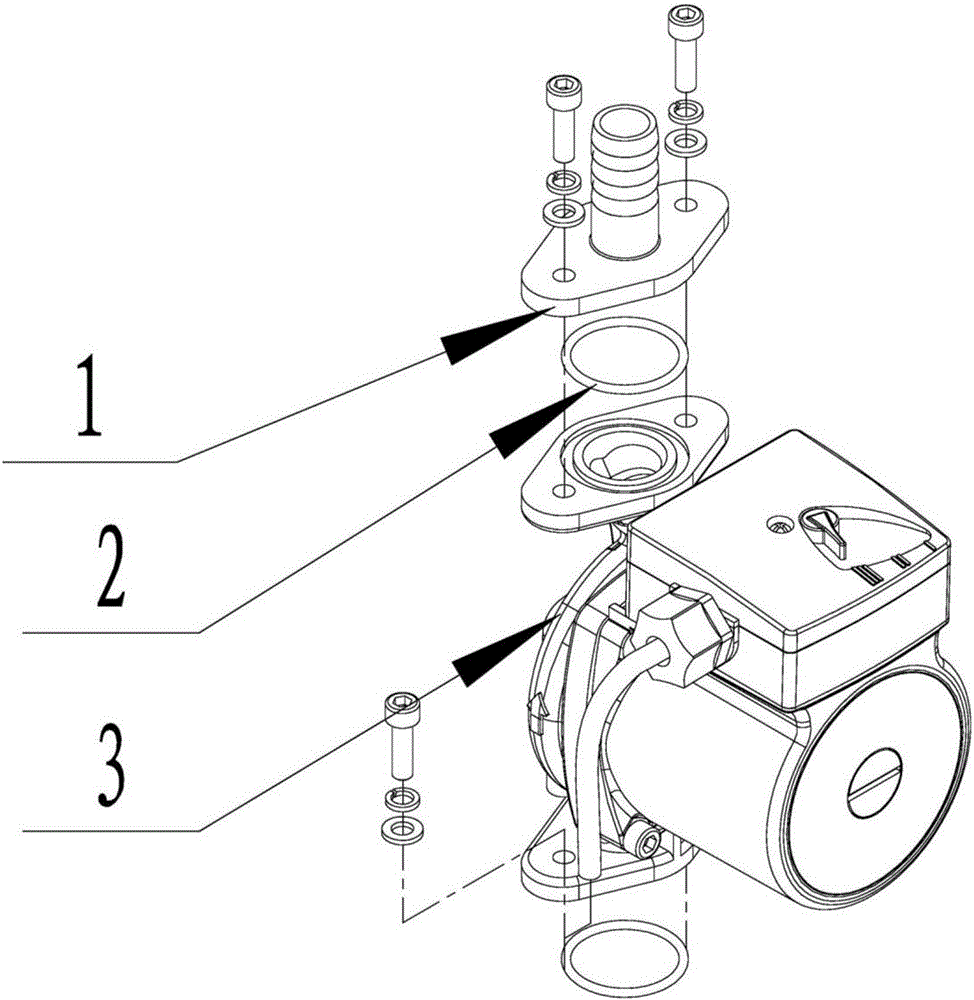

[0033] like Figure 1-6 As shown, the forced circulation engine water heater of the present embodiment includes a water pump main frame 3, a pagoda joint with flange 1 arranged at the upper end of the housing main body 5 of the main machine 3 of the water pump, a pagoda joint 1 with a flange at the lower end of the pagoda joint with a flange and the housing The O-ring 2 between the upper ports of the main body 5, the front housing 4 installed on the left side of the housing main body 5 through the hexagonal socket bolt, the rear housing 25 installed on the right end of the housing main body 5 through the hexagonal socket bolt, and the rear housing 25 installed on the rear shell The mask 24 at the right end of the body 25, the foamed silica gel sealing strip 26 arranged between the rear casing 25 and the right end surface of the casing main body 5, the L bracket 6, and the left side of the vertical plate of the L bracket 6 and the bottom of the L bracket 6 The cabinet body 7 on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com