Air filter of compressor

An air filter and compressor technology, applied in the direction of machine/engine, mechanical equipment, liquid variable capacity machinery, etc., can solve the problems of poor filtering effect, interrupted contact time, small contact area, etc., to improve the filtering effect , the effect of increasing the filtration time and increasing the contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] Embodiments of the present invention are described in further detail below in conjunction with the accompanying drawings:

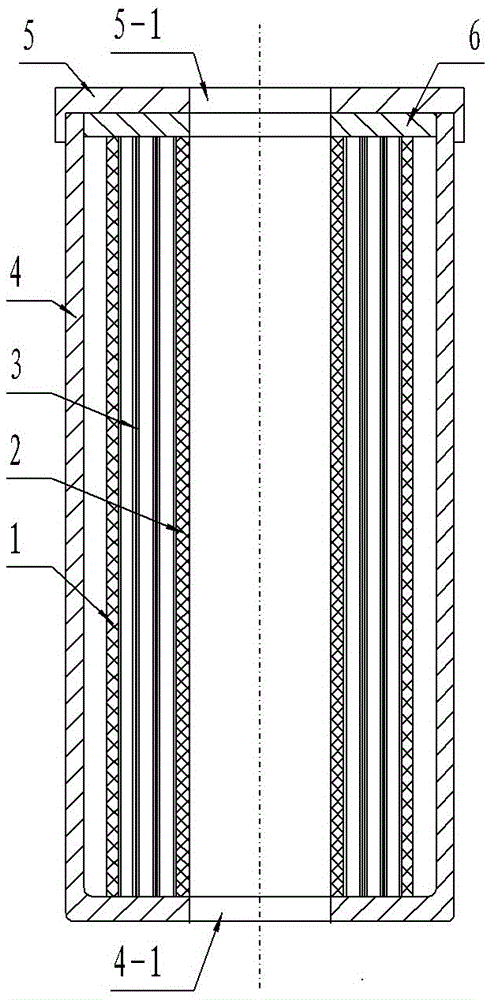

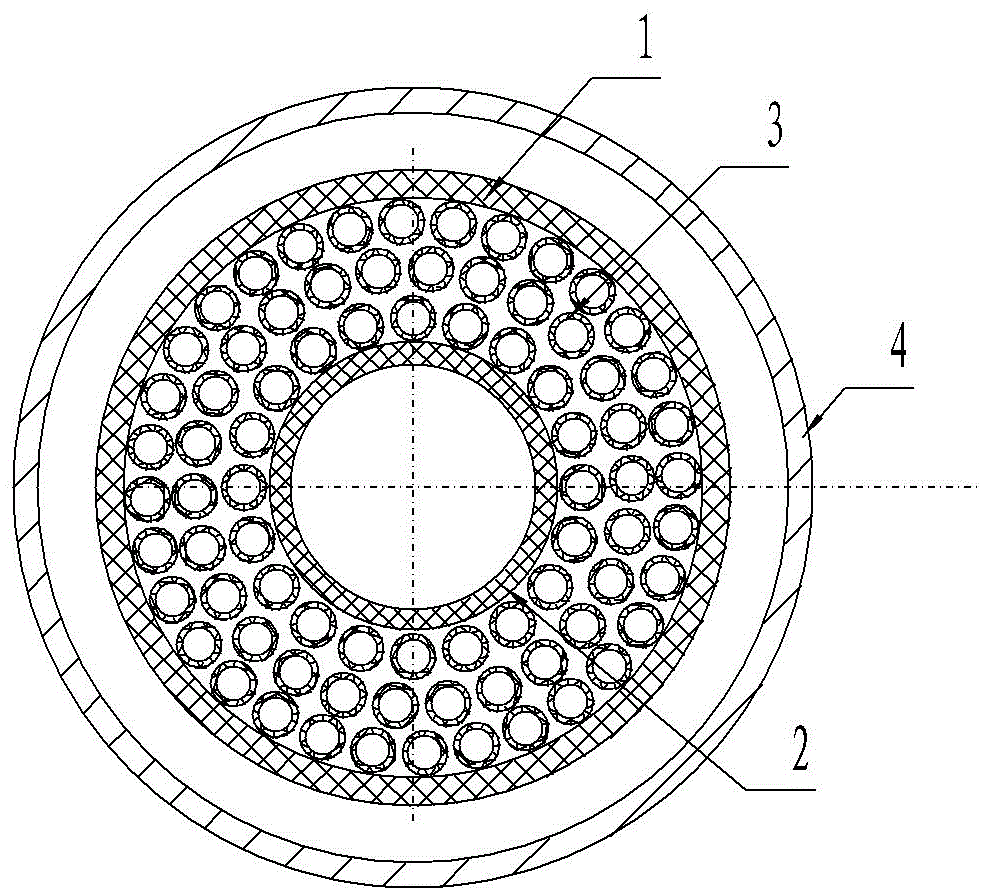

[0011] Such as figure 1 , figure 2 The compressor air filter shown includes a casing 4 with a cover 5, the cover 5 is provided with an air inlet 5-1, the bottom of the casing 4 is provided with an air outlet 4-1, and the casing 4 is provided with an air filter element , the air filter includes two inner and outer cylinders 2 with mesh holes and an outer cylinder 1, the top between the inner cylinder 2 and the outer cylinder 1 is provided with a top cover 6, the inner cylinder 2 and the outer cylinder 1 There are a plurality of cylindrical filter elements vertically arranged in a staggered arrangement. The cylindrical filter element is a carbon fiber cylinder 3, so that the air flow does not directly pass through, but passes through the cylindrical filter element. By bypassing between them, the filtration time is increased. At the same time, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com