An adjustable anchor bolt pre-embedded nut structure

A technology of pre-embedding nuts and anchor bolts, applied in the direction of nuts, connecting components, threaded fasteners, etc., can solve the problems of time-consuming and labor-intensive, affecting the production progress of equipment, and not having the processing capacity of large-scale equipment, etc. good contact effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

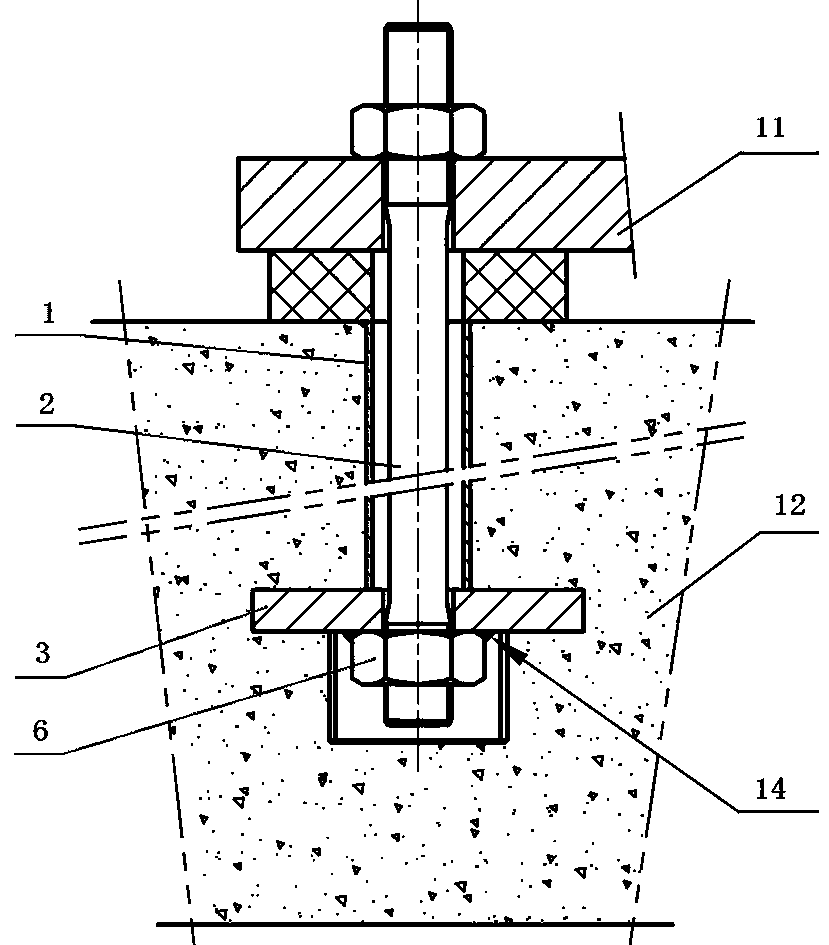

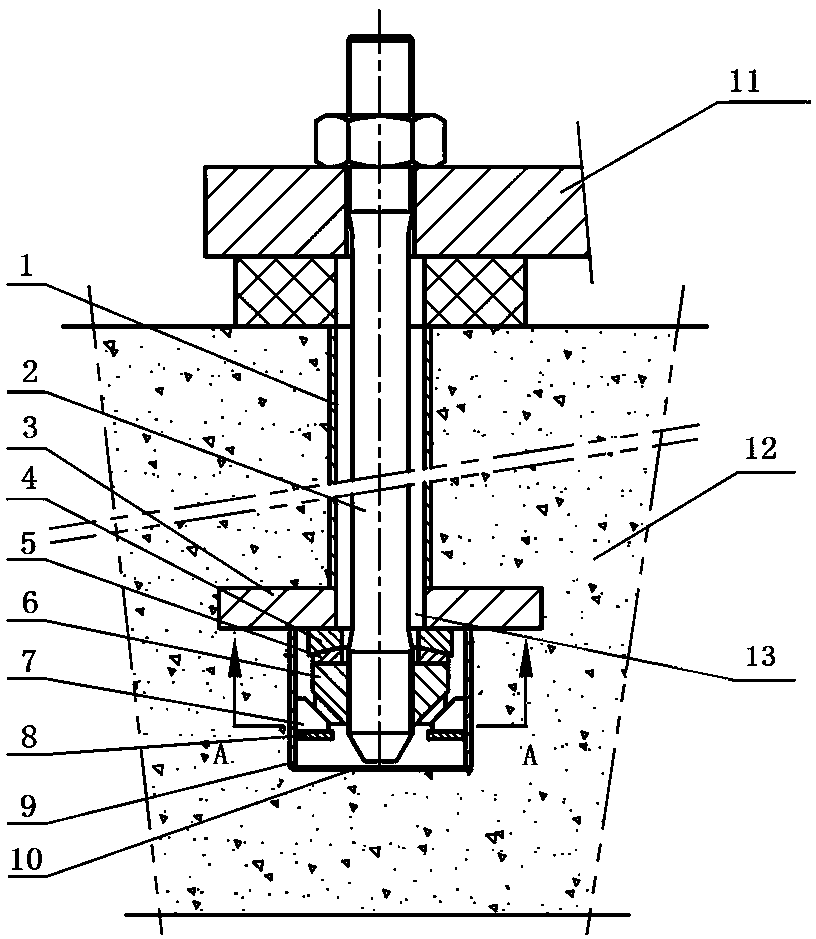

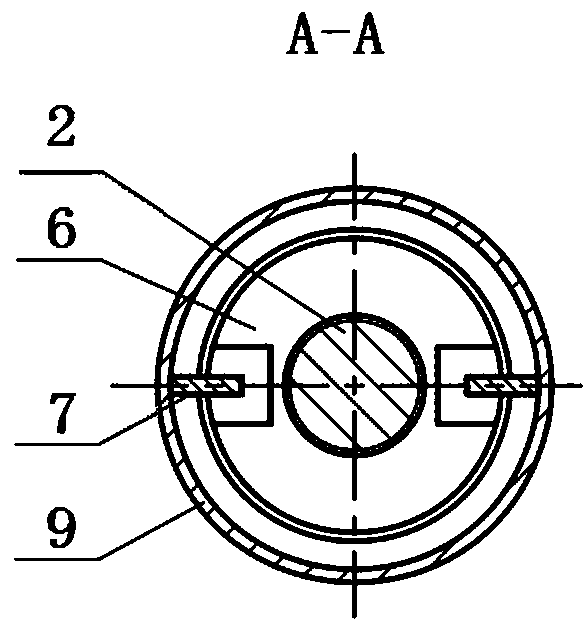

[0022] Such as figure 2 , image 3 Shown: an adjustable anchor bolt embedded nut structure, including sleeve 1, anchor bolt 2, embedded plate 3, concave ring 4, convex ring 5 and embedded nut 6; the sleeve 1 and embedded plate 3 Weld and embed concrete 12 as a whole; the anchor bolts 2 penetrate into the sleeve 1, and the concave ring 4, the convex ring 5 and the embedded nut 6 are respectively put on the position below the buried plate 3; the inner diameter of the sleeve 1 is larger than The outer diameter of the anchor bolt 2 makes the anchor bolt 2 have a horizontal displacement space 13 in the sleeve 1, thereby correcting the position of the movable anchor bolt 2 in the horizontal direction. There is also a stop plate 7, a support ring 8, a sealing ring 9, and a sealing plate 10 welded together with the buried plate 3 below the buried plate 3; the sealed ring 9 is welded with the buried plate 3; the support ring 8 is installed on The middle and lower part of the sealing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com