A Method for Shutdown of a Once-through Boiler with Sliding Parameters

A once-through boiler and sliding parameter technology, applied in steam generation, control systems, lighting and heating equipment, etc., can solve problems affecting normal production, wasting power resources, and taking a long time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to enable those skilled in the art to better understand the technical solutions of the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

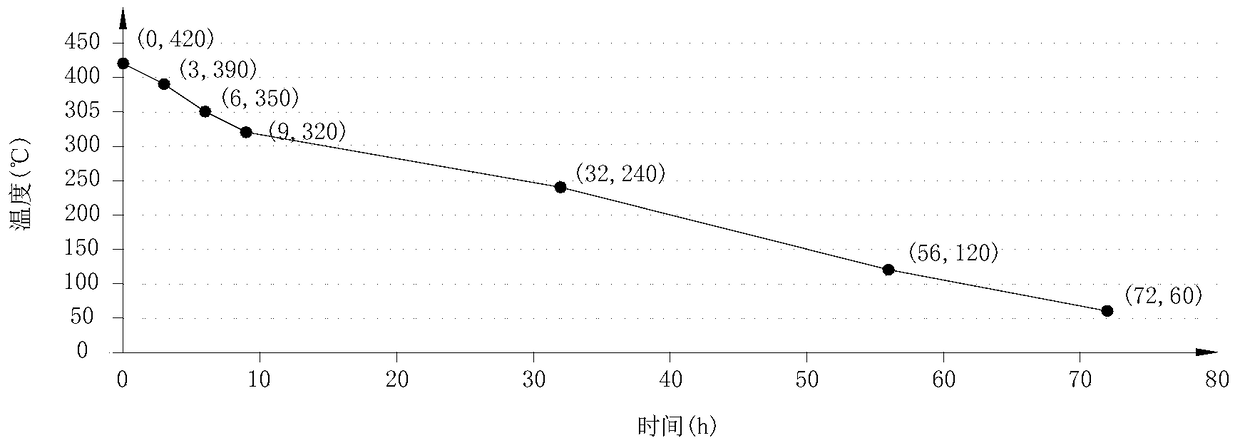

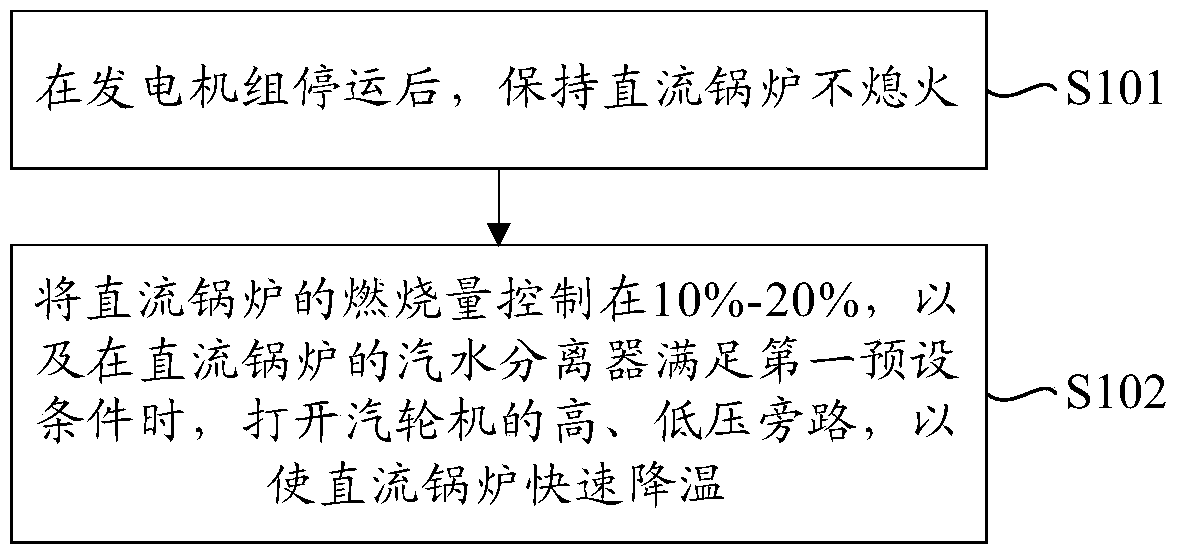

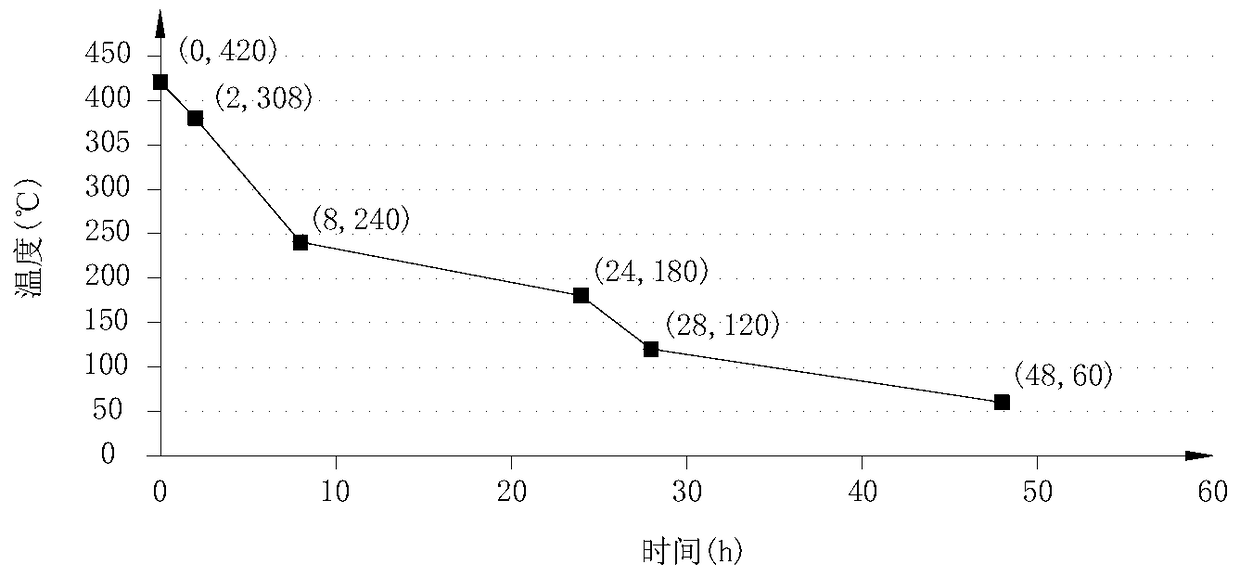

[0028] Such as figure 2 As shown, the embodiment of the present invention provides a method for shutting down a once-through boiler with sliding parameters. The method is applied to a generator set using a once-through boiler. Specifically, the generator set includes a once-through boiler, a steam turbine, a generator and related bypasses. Among them, the once-through boiler includes a steam-water separator, and the steam-water separator is an important part (accessory) of the once-through boiler. Its function is to effectively separate the water contained in the saturated steam and improve the dryness of the steam to ensure the reliable operation of the once-through boiler. , and meet the needs of users. Specifically, the steam...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com