Air-conditioning system for weaving workshop and control method of air-conditioning system

A technology for air conditioning systems and workshops, which is applied in air conditioning systems, heating and ventilation control systems, heating and ventilation safety systems, etc., and can solve the problems of large economic burden and high energy consumption of equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

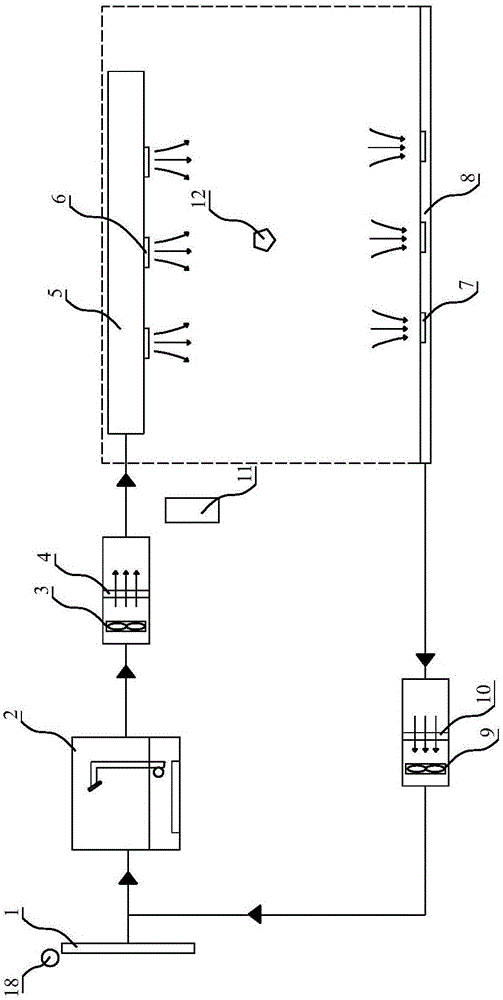

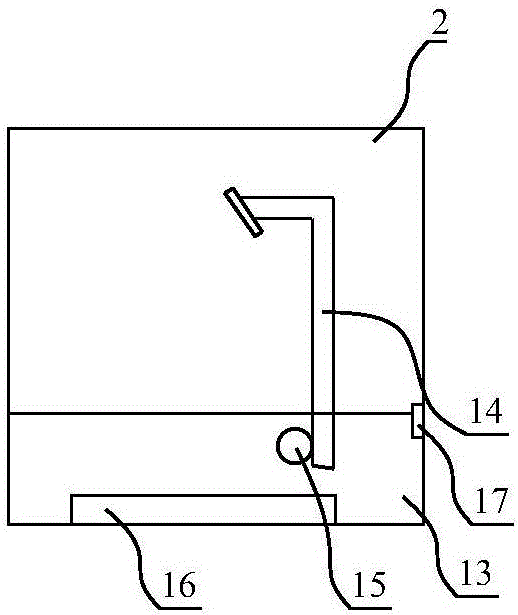

[0026] Attached below Figure 1-3 The present invention is further described:

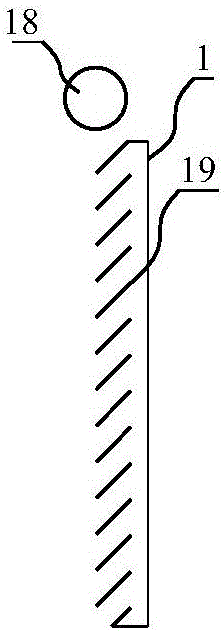

[0027] Please refer to figure 1 , an air conditioning system for a textile workshop, comprising an air inlet 1, a first fan 3, an air supply duct 5, a return air trench 8, a central control system 11, a temperature and humidity sensor 12 arranged in the workshop, and a pipeline connecting the above components The air supply duct 5 is provided with a number of air supply ports 6, and the air return trench 8 is provided with a number of air return ports 7; A first filter screen 4 is arranged between the channel 5 and the inlet fan 3; the spray chamber 2 includes a water collection tank 13, a spray device 14 for taking water from the water collection tank 13, and the water spray direction of the spray device 14 is the same as that of the water collection tank 13. The direction of air entering the spray chamber 2 is opposite; the temperature and humidity sensor 12 is connected to the central control ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com