A heat dissipation architecture applied to storage 2u models

A technology of machine type and air guide frame, which is used in instruments, computing, electrical and digital data processing, etc., can solve the problem of high temperature of the rear hard disk, and achieve the effects of reducing processing accuracy, reducing air intake, and good reliability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

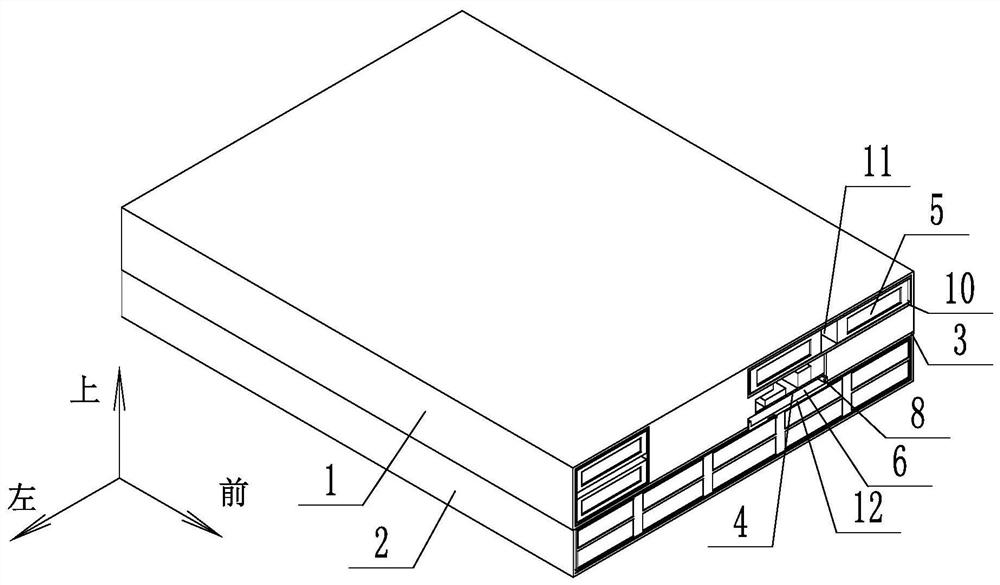

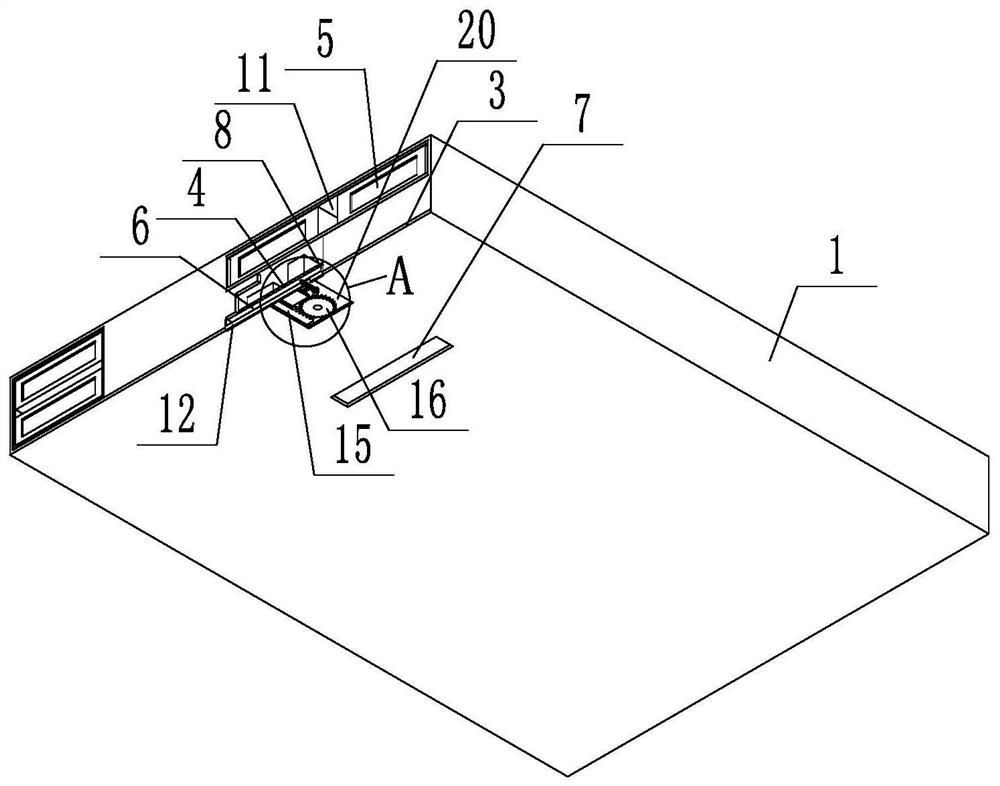

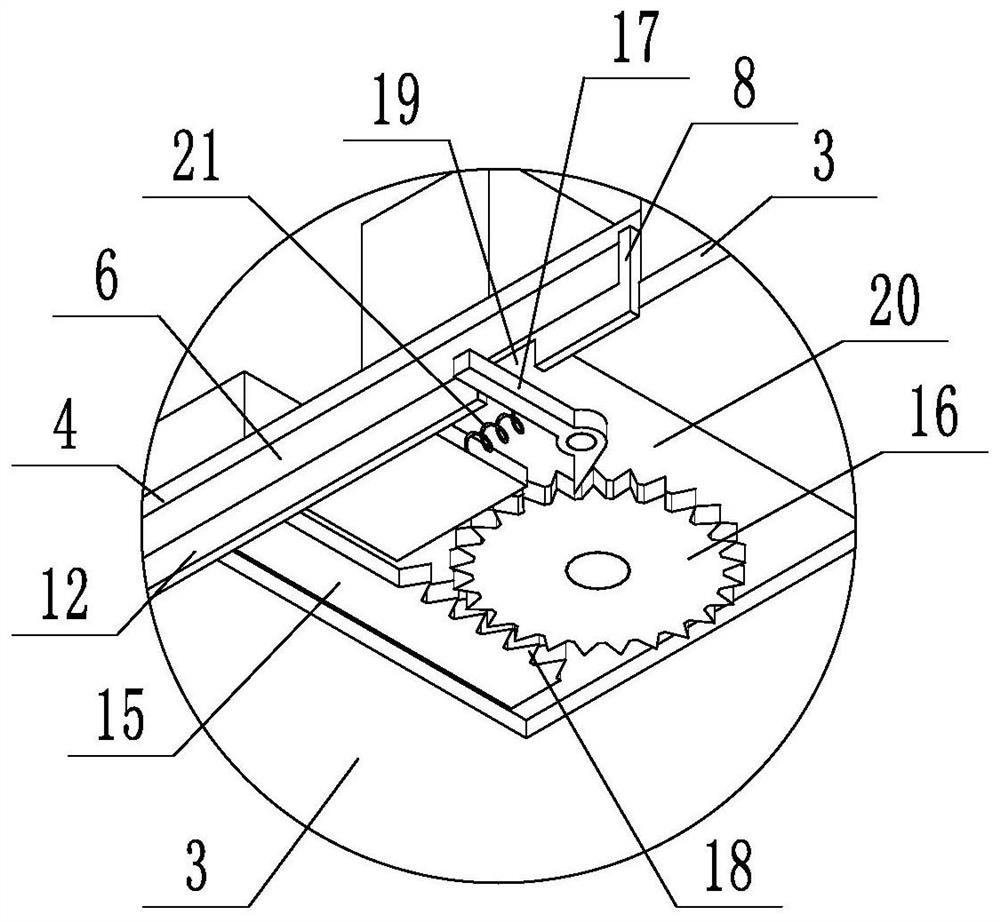

[0038] Such as figure 1 As shown, a heat dissipation architecture applied to a storage 2U model, the storage 2U model includes an upper node 1 and a lower node 2, the upper node 1 is provided with a tray 3, a motherboard 4 and a hard disk 5, and the lower node 2 is provided with multiple The hard disk 5 is arranged in the server through the hard disk bracket 10. It is characterized in that an air duct 6 is provided between the tray 3 and the main board 4, and an opening 7 is provided at the lower end of the tray 3. Corresponding to the hard disk 5, the opening 7 communicates with the air duct 6, the air duct 6 is provided with an air guide frame 8, and the front end of the air guide frame 8 is provided with an arc portion 9, and the arc portion 9 corresponds to the opening 7, and the upper node 1 A gap 11 is provided between the two hard disks 5 in the hard disk bracket 10 . The hard disk bracket 10 is installed in the case, and its installation method is the prior art, so it...

Embodiment 2

[0052] Such as Figure 10 and Figure 11 As shown, the lower end of the air duct 6 is fully open, so that the air flow in the air duct 6 can blow to the three rows of hard disks in the lower node. The air guide frame 8 and the slideway 28 are locked by the second locking screw 29, the front end of the air guide frame 8 is provided with a second positioning block 30, the rear end of the air duct 6 is provided with a positioning groove 31, and the second positioning block 30 and the positioning groove 31 fits. When installing the air guide frame 8, the air guide frame 8 is inserted deep into the air duct 6 along the positioning groove 31 until the second positioning block 30 matches the positioning groove 31, and then the second locking screw 29 locks the air guide frame 8 and the slide Road 28, the wind guide frame 8 is fixed.

[0053] Such as Figure 12 and Figure 13 As shown, the lower end of the wind guide frame 8 is provided with a third groove 32 , and the second foa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com