Metallurgical cooling and air-drying mechanism

A technology of metallurgy and cooling section, which is applied in the field of metallurgical cooling and air-drying mechanism, which can solve the problems of blank influence, uneven cooling of blank, quality of blank and influence of follow-up process, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

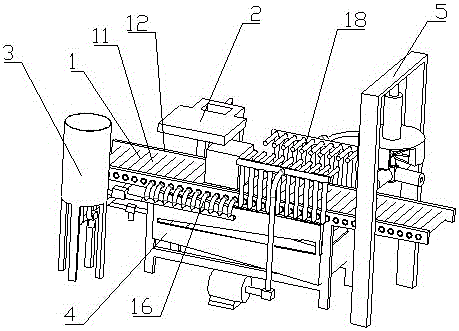

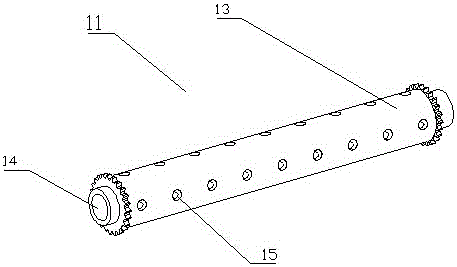

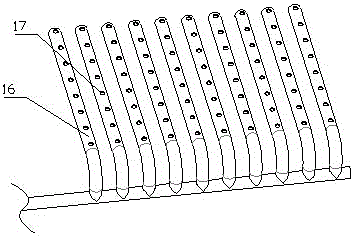

[0032] see Figure 1 to Figure 6, the present invention provides a metallurgical cooling air-drying mechanism, comprising a conveyor belt 1, and a cooling section and an air section arranged on the conveyor belt 1 in sequence. The conveying direction of the conveyor belt 1 is from the cooling section to the air section direction. Linkage of other metallurgical links, the conveyor belt 1 is a sprocket power roller conveyor belt, the conveyor belt 1 runs through the entire cooling mechanism; the conveyor belt 1 includes a roller 11 and a chain box 12, the two ends of the roller 11 and the chain box 12 are connected by bearings, and the roller 11 is connected by the chain box The chain in 12 drives to rotate; The sprocket wheel power roller type conveyer belt is to be driven chain by motor, has the conveyer belt of chain driven roller again, and this is prior art, repeats no more at this. The cooling unit includes a shower head 2 arranged above the conveyor belt 1, the shower hea...

Embodiment 2

[0048] see Figure 7 and Figure 8 , on the basis of Embodiment 1, the airflow nozzle 58 is vertically arranged on the lower side of the telescopic rod 51 of the water wiping mechanism 5, the airflow nozzle 58 is connected with the air pump through the air pipe, and the high pressure airflow is provided by the air pump, and the airflow nozzle 58 is sleeved on the rotating shaft 52 On the outside, the rotating shaft 52 is cylindrical, the air flow nozzle 58 is coaxial with the rotating shaft 52, and an annular ring gear 59 is arranged along its top; A driving wheel 61 is provided, the driving wheel 61 meshes with the driven wheel 62 , the driven wheel 62 is coaxial with the worm 63 , and the worm 63 meshes with the ring gear 59 . When the blank reaches the water-wiping structure 5, the airflow nozzle 58 sprays a high-pressure airflow to impact the upper surface of the blank, while the sponge roller 54 rotates under the drive of the rotating shaft 52, so as to better protect th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com