Novel vending machine delivery mechanism

A vending machine, a new type of technology, applied in the direction of instruments, coin-operated equipment for distributing discrete items, coin-operated equipment for distributing discrete items, etc., can solve the inconvenience of loading, high cost, slow delivery speed, etc. problems, to achieve the effect of compact structure, convenient loading and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

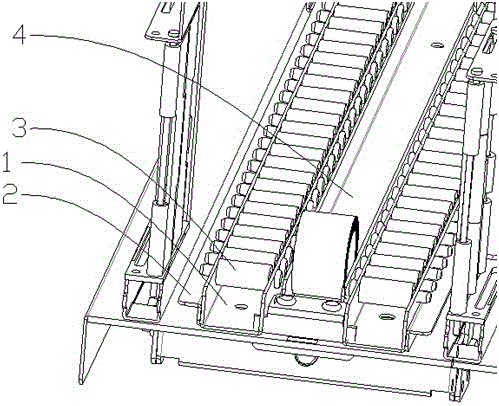

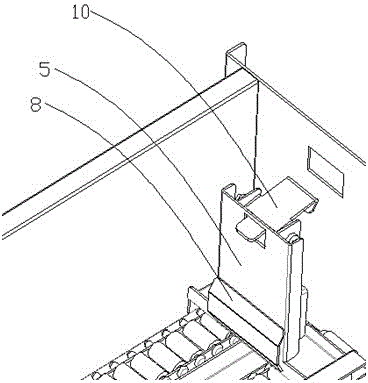

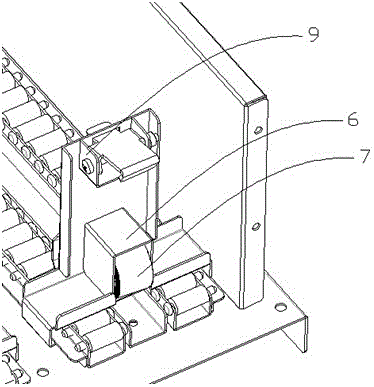

[0034] see figure 1 — Figure 8, a new type of automatic vending machine delivery mechanism of the present invention, including a tray, a push mechanism and a baffle mechanism, the tray is connected and fixed by a base, a rear seat and a partition, and the partition is installed on the base to divide the tray into several Cargo lane; the push mechanism includes a slideway part and a push plate part, the slideway in the slideway part adopts a U-shaped slideway, and a coil spring groove is arranged in the middle of the two U-shaped slideways; the push plate main body in the push plate part The front protrusion of the push plate, the coil spring box and the lock bracket are installed. A coil spring is installed in the coil spring box. One end of the coil spring stretches through the square hole at the bottom of the main body of the push plate, and is finally fixed on the front end of the coil spring slot through the coil spring slot. The lock is installed on the bracket, corresp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com