Method for preparing LED chips with positive, inverted and inverted trapezoidal mesa substrates by stealth dicing

A technology of LED chips and stealth cutting, applied in semiconductor devices, electrical components, circuits, etc., can solve the problems of limited light extraction efficiency and complex process, and achieve a simple and stable process that promotes escape probability and short preparation time. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

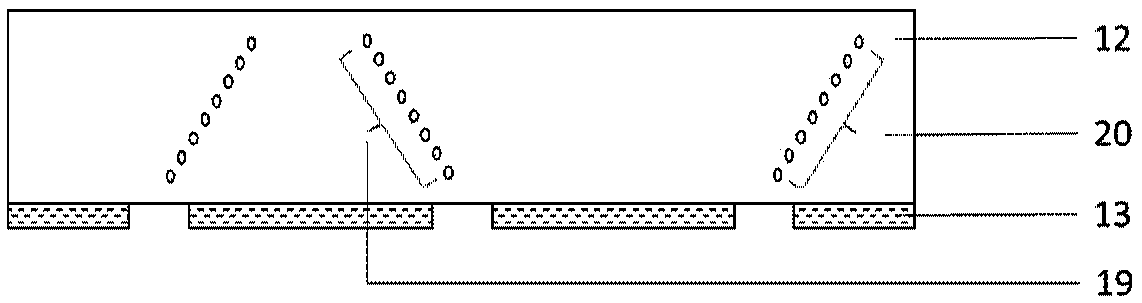

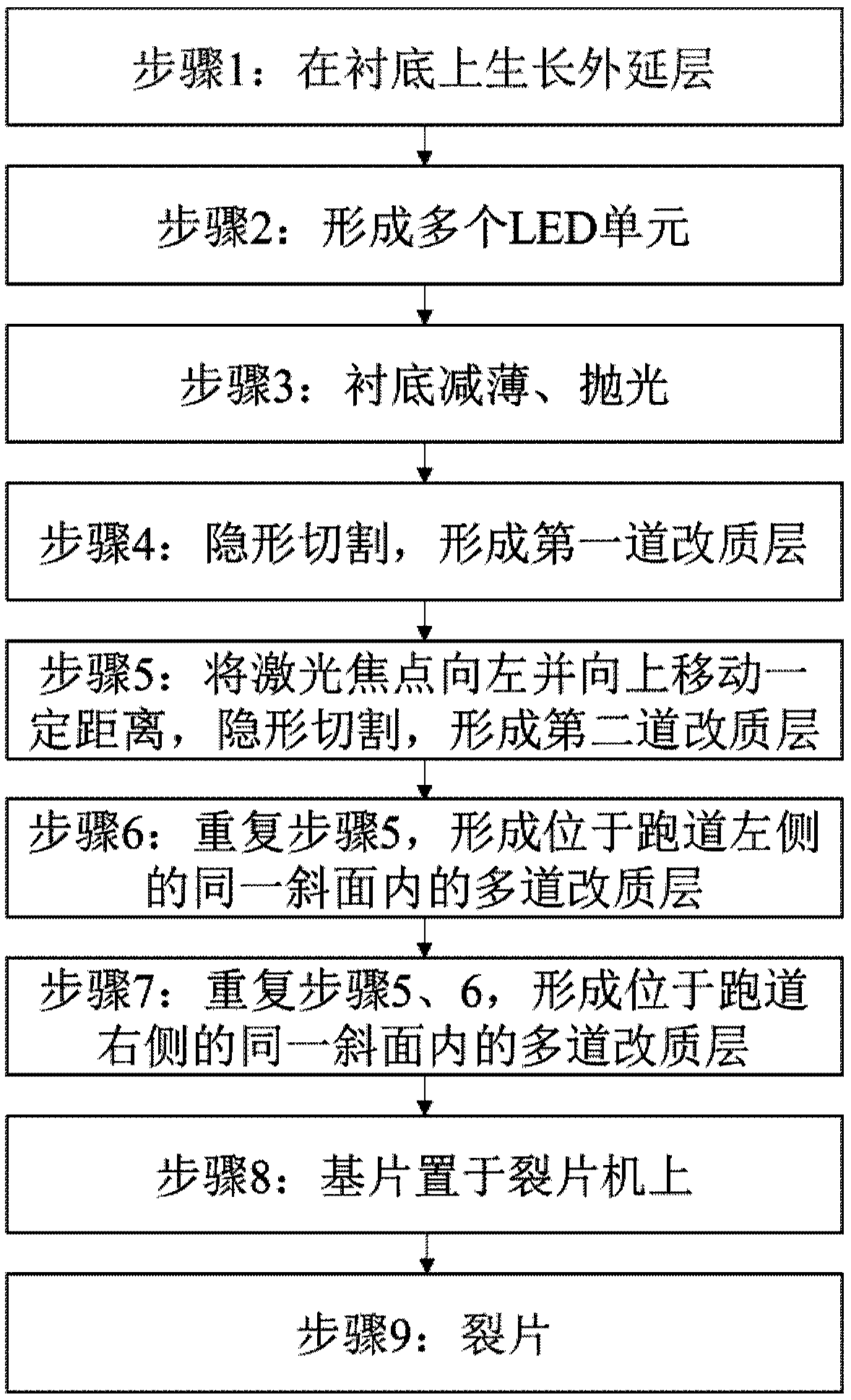

[0040] see Figure 4 to Figure 7 , the present invention provides a method for stealth cutting and preparing an LED chip of an inverted trapezoidal mesa substrate, comprising the following steps:

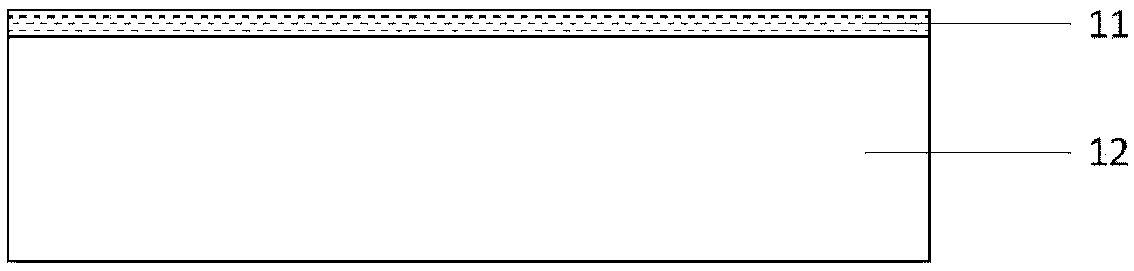

[0041] 1) Provide a substrate 12, grow an epitaxial layer 11 on the front side of the substrate 12, the material of the epitaxial layer 11 is a GaN-based III-V group material, and the thickness of the epitaxial layer 11 is 2-20 μm, The material of the substrate 12 is sapphire, silicon carbide, gallium nitride, aluminum nitride, gallium oxide or glass.

[0042] 2) On the epitaxial layer 11, processes such as photolithography, etching, metal evaporation and passivation are used to form a plurality of LED units 13; in order to improve the quality and yield of subsequent splits, the LED units 13 can be used together on the track Laser scribing and / or etching creates the grooves.

[0043]3) Thinning and polishing the substrate 12, adhering the backside up on the blue film, and placing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com