Electrical connector for flat conductor

A flat conductor and electrical connector technology, applied in the direction of connection, parts and circuits of the connection device, can solve the problems of unqualified contact and damaged connecting parts, and achieve the effect of preventing unqualified contact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

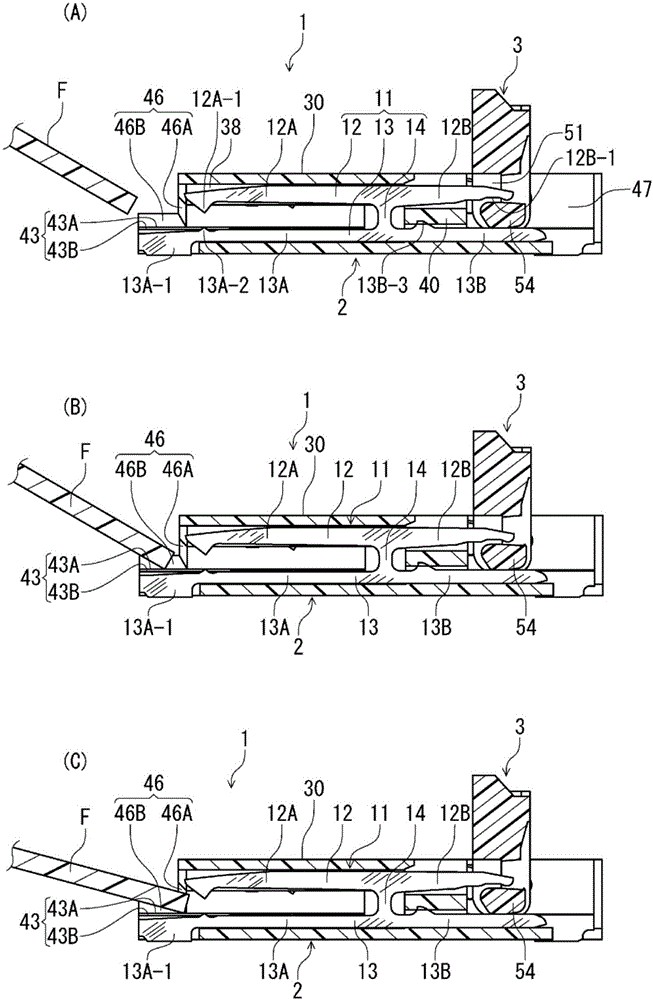

[0026] Hereinafter, embodiments of the present invention will be described based on the drawings.

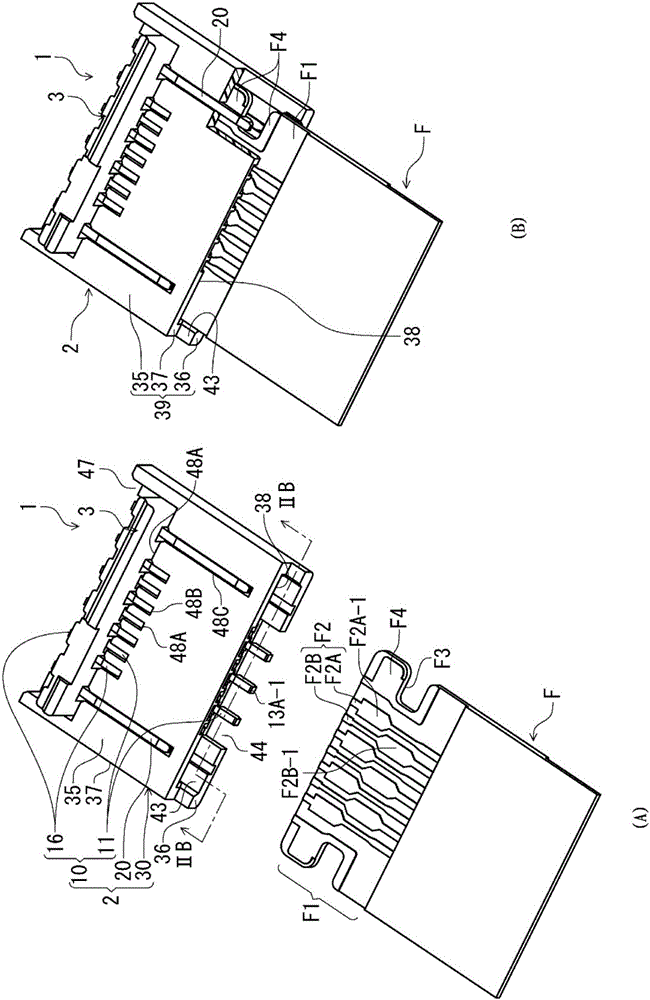

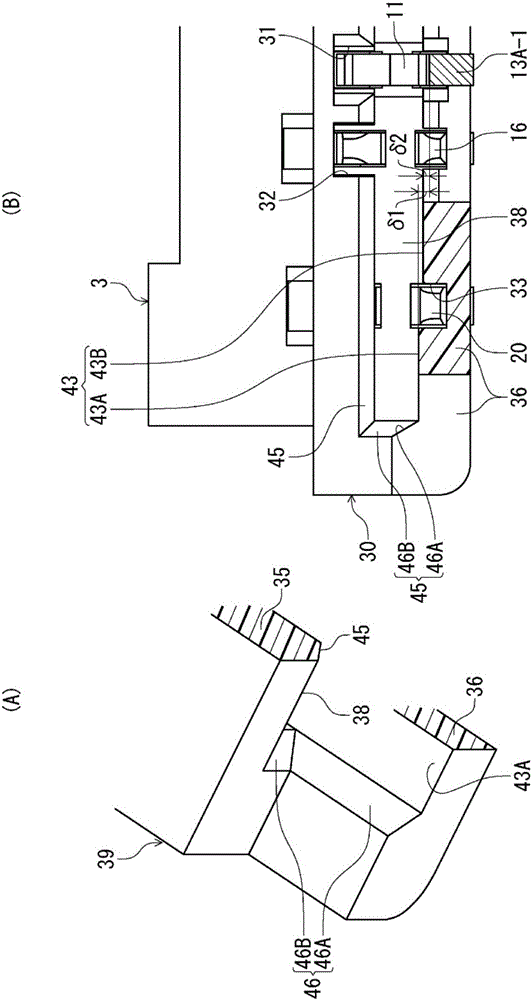

[0027] figure 1 It is a perspective view showing an electrical connector for a flat conductor (hereinafter referred to as a connector) 1 and a flat conductor F connected thereto according to the present embodiment, (A) showing before the flat conductor is connected to the connector 1, and (B) showing the connection after.

[0028] The flat conductor F has, on the upper surface of the front end portion of the flat conductor F, a connection portion F1 which is introduced into the connector 1 and connected to a terminal of the connector. In this embodiment, circuit lines extending along the longitudinal direction of the flat conductor (only the front end portion where the connection portion F1 is formed is shown in the figure, and the rear portion is omitted) are arranged in a number corresponding to the number of the above-mentioned terminals. F2, the circuit line F2 has a circu...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap