Full-automatic bulb replacement manipulator

A technology for changing light bulbs and manipulators. It is applied in the direction of manipulators, electrical components, manufacturing tools, etc. It can solve problems such as high installation position of light bulbs, electric shock of light bulbs, and inability to directly replace light bulbs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

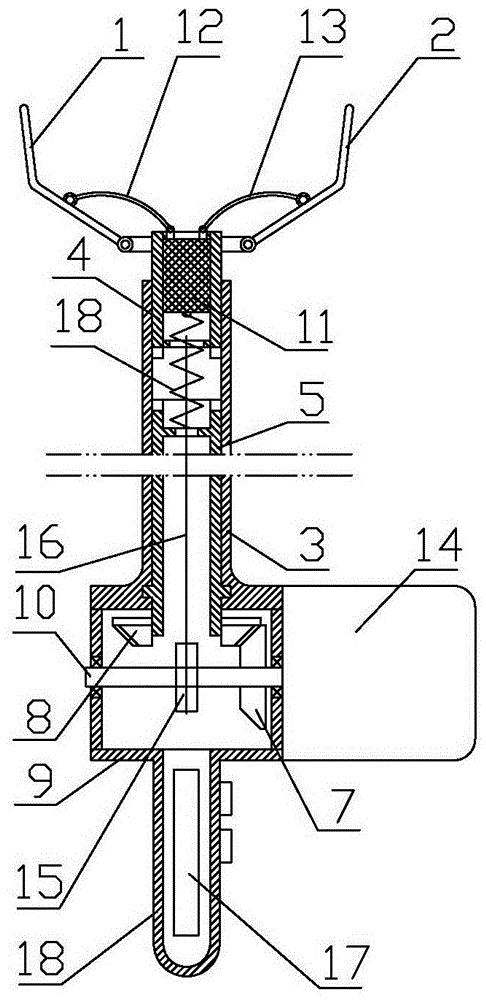

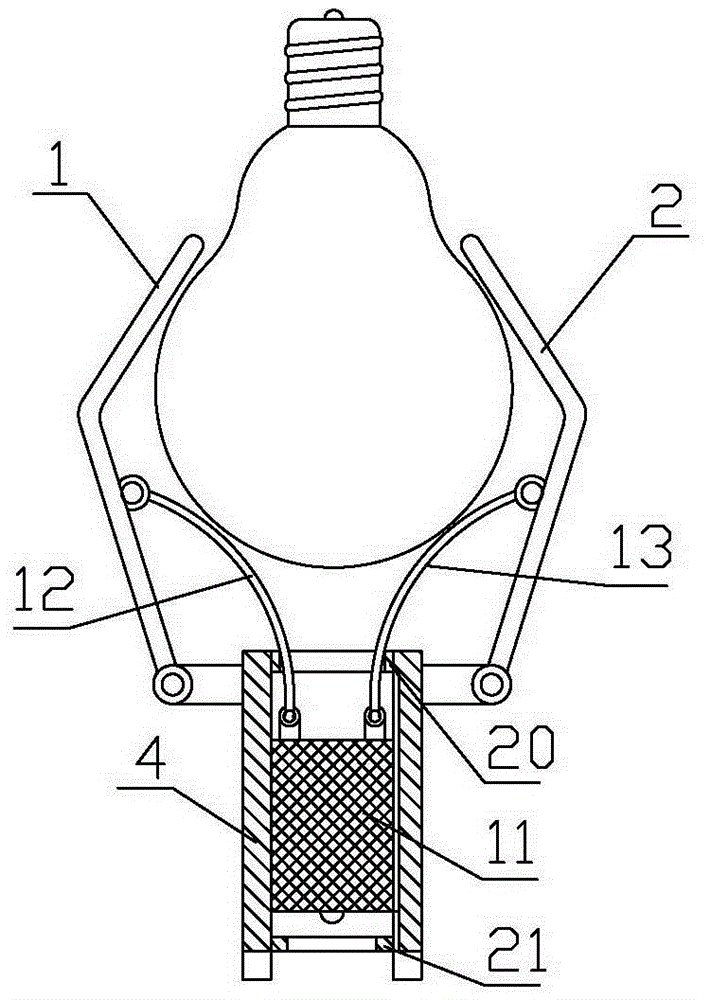

[0011] Such as figure 1 , figure 2 As shown, the fully automatic light bulb changing manipulator of the present invention includes a telescopic rod, a plurality of clamping claws 1 and 2 that are installed on the upper end of the telescopic rod and can be relatively contracted. That is, the light bulb that can reach a high place can hold the light bulb when the multiple clamping claws 1 and 2 shrink to complete the work of changing the light bulb. Just can hold spherical bulb, can also paste soft fabric layer on the inner side of clamping bar 1,2 in order to increase frictional force.

[0012] The telescopic rod includes an outer sleeve 3, an upper rod body 4, and a lower rod body 5, and the upper end of the outer sleeve 3 is hinged with the lower ends of the clamping claws 1, 2; the upper rod body 4 and the lower rod body 5 are all rotatably installed In the tubular structure in the inner cavity of the outer sleeve 3, the upper rod body 4 can rotate or move axially in the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com