Method for assembling corrugated bulkhead block

An assembly method and bulkhead technology, which is applied in transportation and packaging, shipbuilding, ships, etc., can solve the problems of difficult welding, poor welding quality, and poor operation safety performance, so as to improve the operation safety factor and shorten the construction period , Improve the effect of welding quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

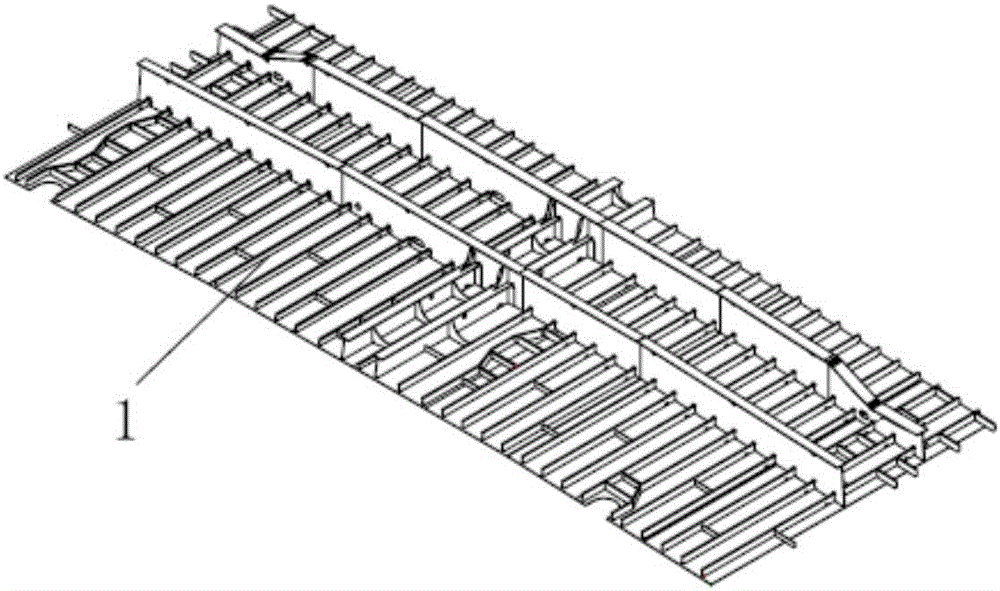

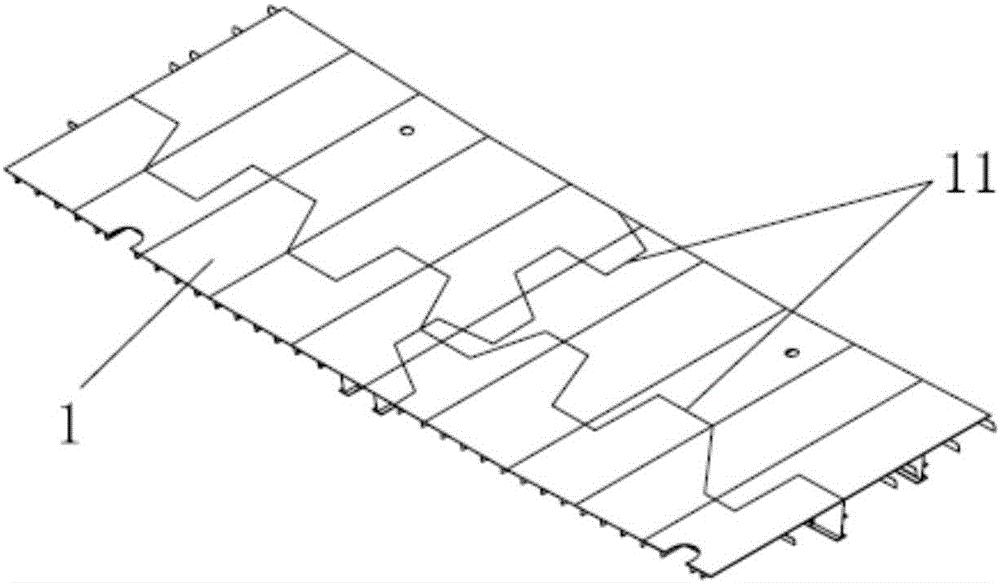

[0040] The invention provides a method for assembling the general section of the trough bulkhead, specifically refer to Figure 2 to Figure 5 , the method for assembling the general section of the corrugated bulkhead includes the following steps:

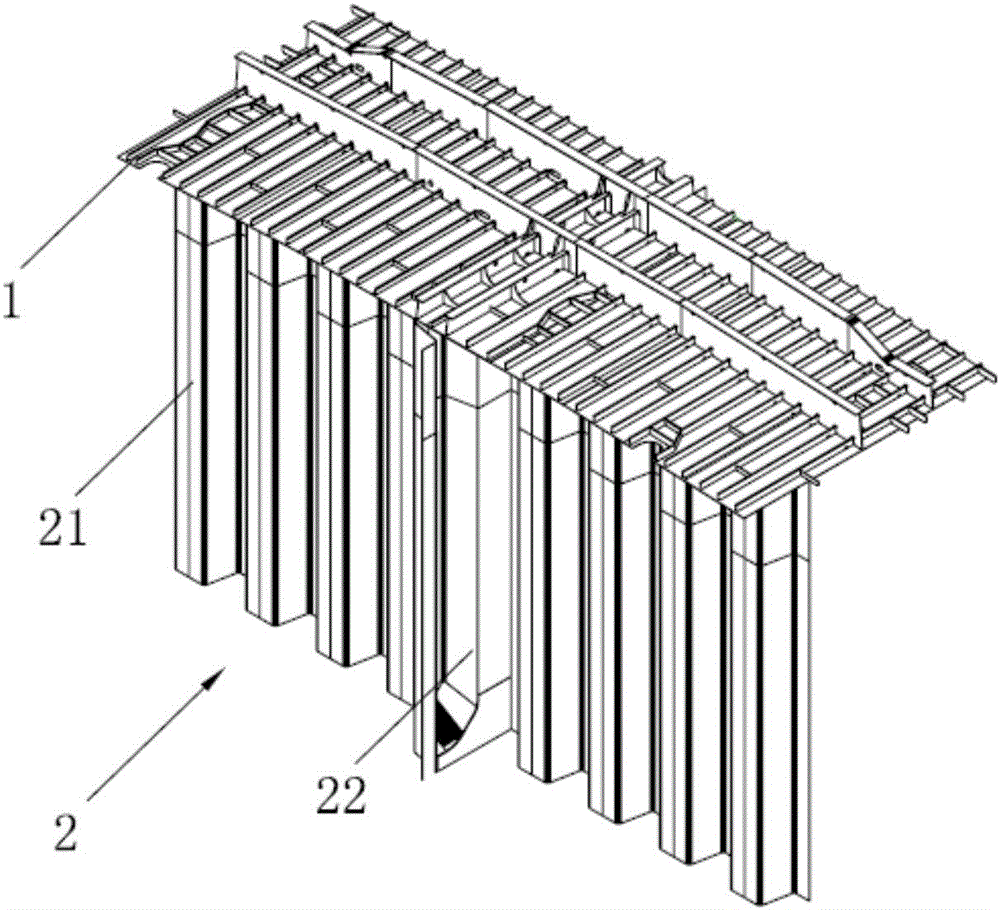

[0041] S1. Hoist the deck in sections to the flipping area so that the reverse side faces upwards.

[0042] First calculate the weight of the total section of the corrugated bulkhead, wherein the total section of the corrugated bulkhead includes the deck section 1 and the section 2 of the corrugated bulkhead, and the section 2 of the corrugated bulkhead includes the transverse corrugated bulkhead 21 and placed in the thickness direction of the transverse corrugated bulkhead 21 ( Figure 4 The longitudinal corrugated bulkhead 22 on both sides shown in th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com