Tarpaulin open-top container

A container and tarpaulin technology, applied in the field of containers, can solve problems such as structural operation troubles, waste of manpower, water leakage, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

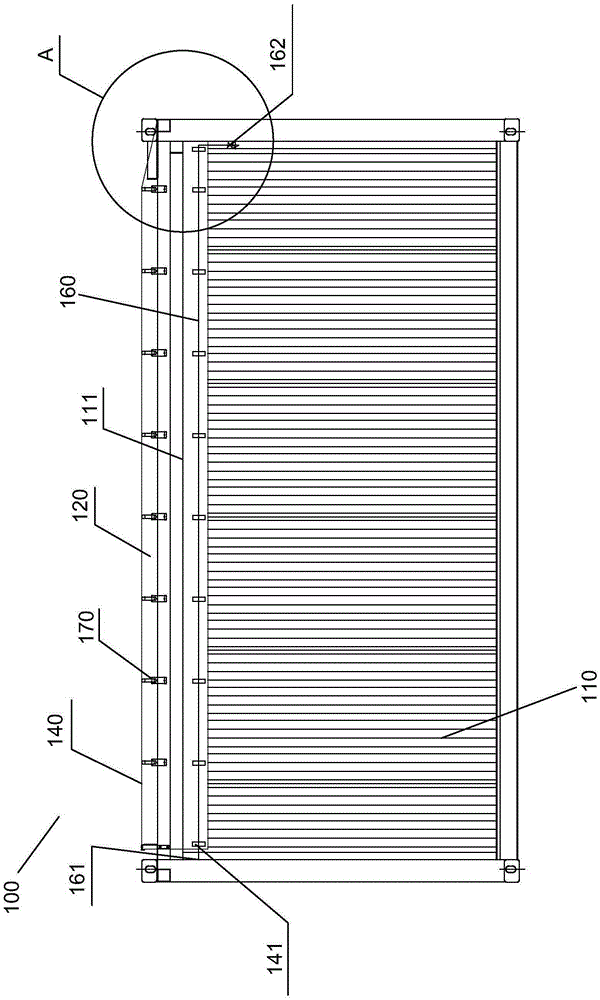

[0046] Figure 1-Figure 2 The first embodiment of the tarpaulin open top container of the present invention is schematically shown.

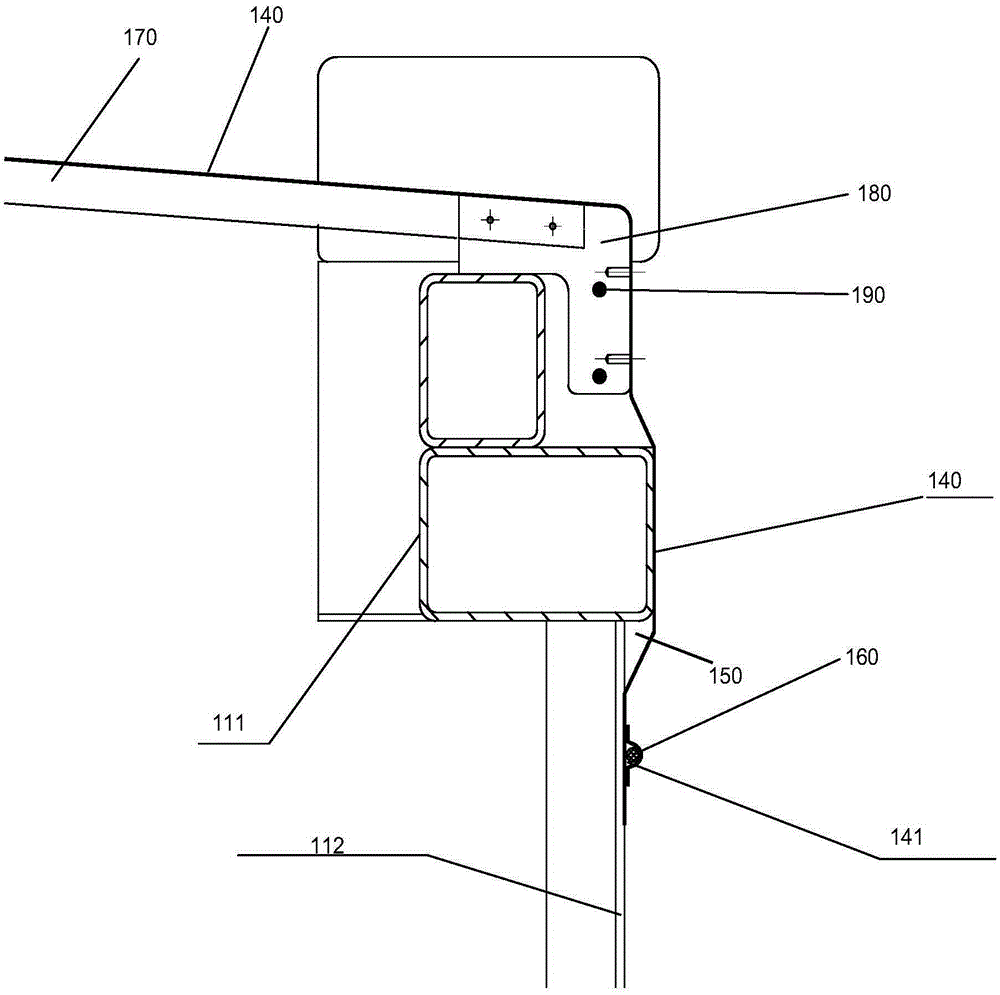

[0047] The box body 110 of the tarpaulin open-top container 100 includes a top side beam 111 extending longitudinally along the box body. The top side beam 111 is located at the top 130 of the box body 110. The top side beam in the present invention is the end beam at the top, which can be is the top side, or it can be the top face. The top 130 of the case has an opening 120 . The top of the box is provided with at least one (eg 5-20) top bows 170 extending laterally along the box, and the top bows 170 are arranged roughly parallel to the end surface of the box. Both ends of the top bow 170 are provided with sliders 180 , and the sliders 180 are arranged on the top side beams and can slide relative to the top side beams 111 along the longitudinal direction of the box body. The slider 180 may be provided with holes or depressions, and these ho...

no. 2 approach

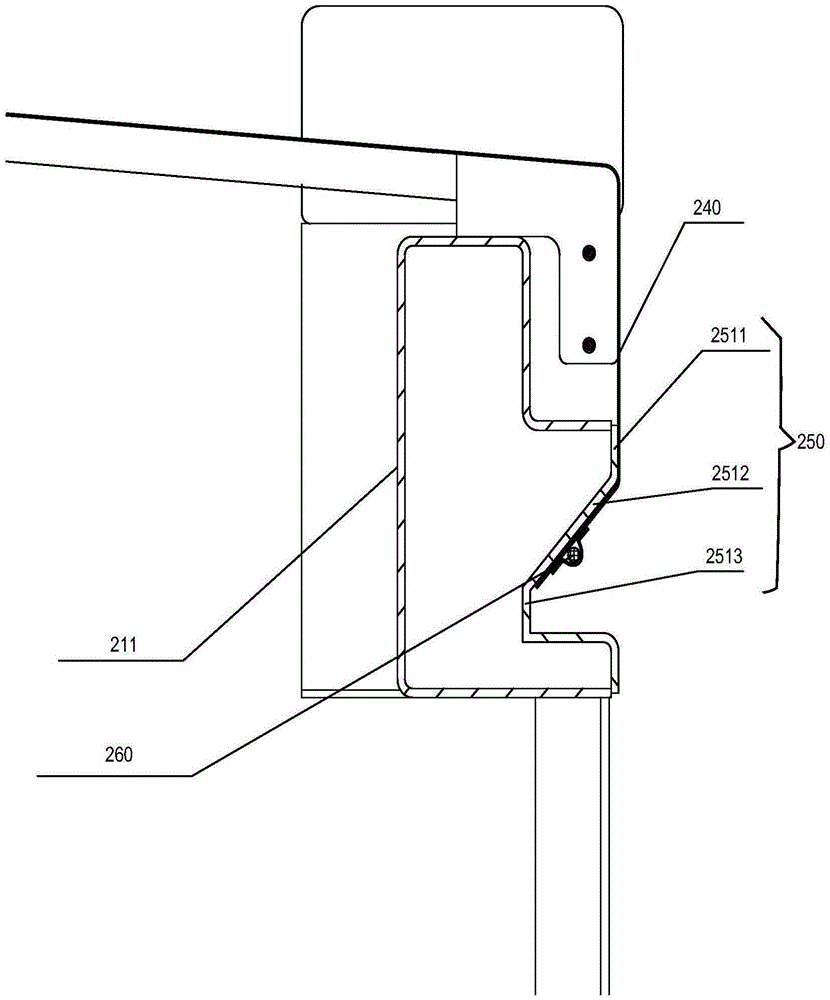

[0053] In this embodiment, for the sake of brevity, descriptions of the same parts as those in the first embodiment are omitted here. In this second embodiment, the reference numerals of the components corresponding to the first embodiment are the same, except that the first digit is changed from "1" to "2". This embodiment differs from the first embodiment in that, as image 3 As shown, a stepped portion 250 is formed on the outer wall of the top side beam 211 , and the stepped portion 250 can be formed by pressing the top side beam 211 . The stepped portion 250 includes a first extension 2511 , a second extension 2512 and a third extension 2513 , the first extension 2511 is the outer surface of the top side beam and extends downwards, the second extension 2512 extends from the first extension 2511 The bottom end of the second extension portion 2512 extends downwards from the bottom end of the second extension portion 2512 . The included angle between the first extension pa...

no. 3 approach

[0055] In this embodiment, for the sake of brevity, descriptions of the same parts as those in the second embodiment are omitted here. In this third embodiment, the reference numerals of the components corresponding to the second embodiment are the same, except that the first digit is changed from "2" to "3". This embodiment differs from the second embodiment in that, as Figure 4 As shown, the included angle between the first extension part 3511 and the second extension part 3512 is 90 degrees, the first end of the sealing rope 360 can be arranged on the third extension part 3513 through bolt connection, and the second end of the sealing rope 360 It can be tightened to the other end of the third extension part 3513 , so that when the second end of the sealing rope 360 is tightened, the sealing rope 360 drives the tarpaulin 340 to be pressed against the first extension part 3511 and the third extension part 3513 . The structure is easy to process and facilitates the for...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com