Active Vibration Damper For A Linear Propulsion System Of Ropeless Elevator

A linear propulsion and elevator system technology, applied to elevators in buildings, non-rotating vibration suppression, elevators, etc., can solve problems affecting the quality of rides

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

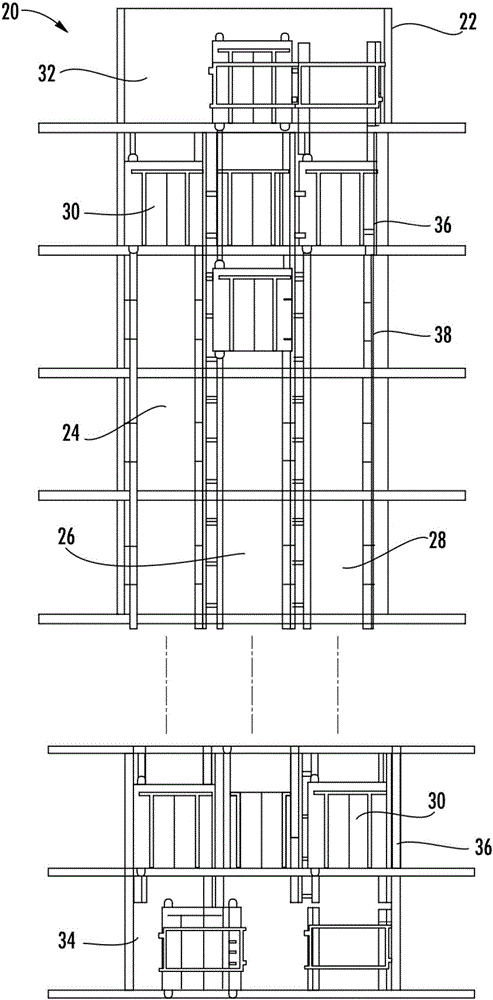

[0034] refer to figure 1 Elevator system 20 may include a fixed support structure 22 (which may typically be an integral part of a multistory building) and at least one passageway or hoistway (i.e., the three hoistways 24, 26, 28 shown) having boundaries generally defined by structure 22. ). System 20 also includes at least one car 30 traveling within at least one of hoistways 24 , 26 , 28 . Car 30 may travel in a vertical direction, and may also travel in a dedicated upward direction in hoistway 26 and in a dedicated downward direction in hoistway 28 (as one non-limiting example). It is also contemplated and understood that the elevator system 20 may be self-propelled and may have a plurality of cars 30 traveling in any of the hoistways 24, 26, 28, with the plurality of cars traveling upward in the hoistway 26. and travel in the hoistway 28 in a downward direction.

[0035] The elevator system 20 may also include an upper transfer station 32 and a lower transfer station 34...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com