Connecting structure of water level probes and bottle body and beverage bottle adopting structure

A water level probe and connection structure technology, applied in the field of beverage bottles, can solve problems such as the inability to adjust the working time of the water pump, reduce the service life of the water pump, and slow water discharge from beverage bottles, so as to delay the start-up time, reduce the gas content, and stabilize the water discharge effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

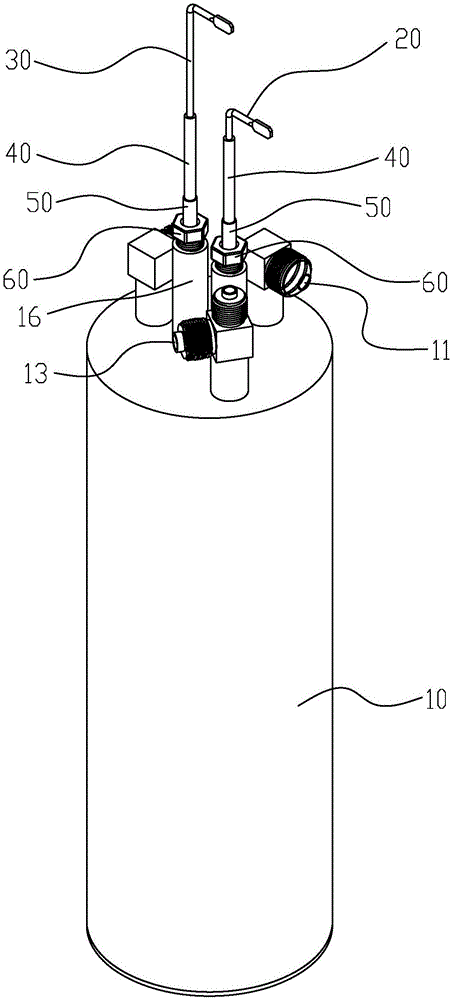

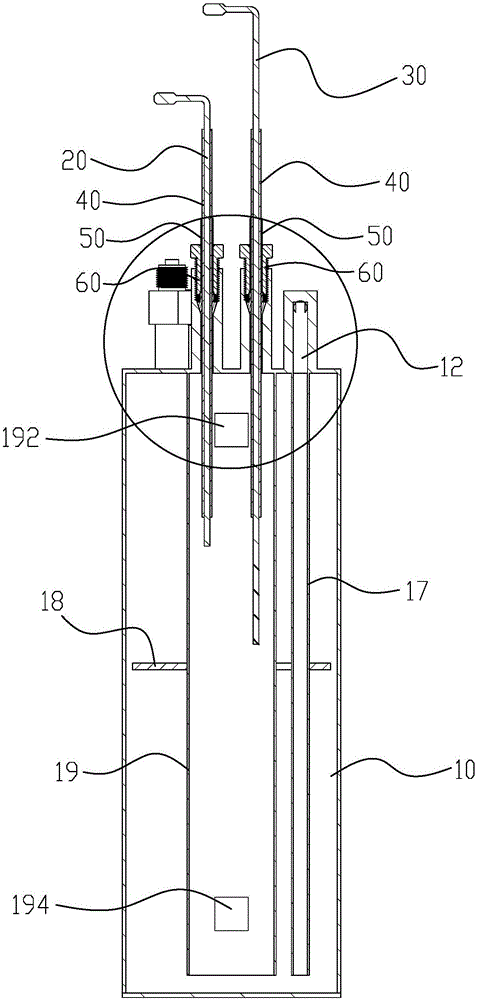

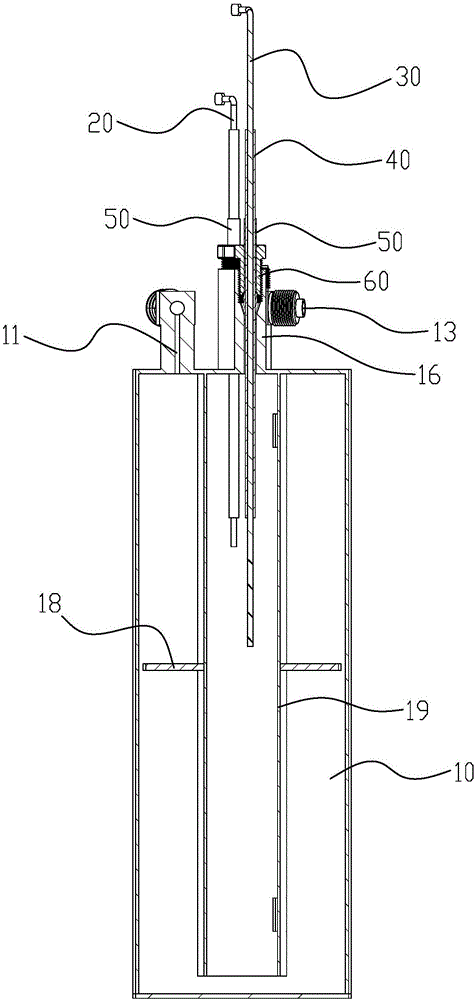

[0030] Please refer to Figure 1 to Figure 4 , a kind of beverage bottle of the present invention, comprises bottle body 10, high water level probe 20, low water level probe 30, described bottle body 10 top is provided with water inlet hole 11, water outlet hole 12, air inlet hole 13, height, The lower ends of the low water level probes 20 and 30 extend into the bottle body 10, and the bottom ends of the low water level probes 30 are positioned below the bottom ends of the high water level probes 20. The high and low water level probes are sheathed with plastic sleeves 40 respectively. It also includes two fastening sleeves 50 that are slidably worn on the two plastic sleeves 40 respectively. The top of the bottle body 10 is respectively provided with two installation holes 14 corresponding to the two fastening sleeves. The fastening sleeves 50 are partially inserted into the installation Inside hole 14. There is a pair of tapered surfaces 52 and 15 opposite to each other bet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com