Truck hopper unloading frame

A technology of truck body and truck, which is applied in the directions of loading/unloading, transportation and packaging, and roller table, etc. It can solve the problems of easy-to-break goods, low work efficiency, and poor adaptability of truck body, and achieve strong adaptability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

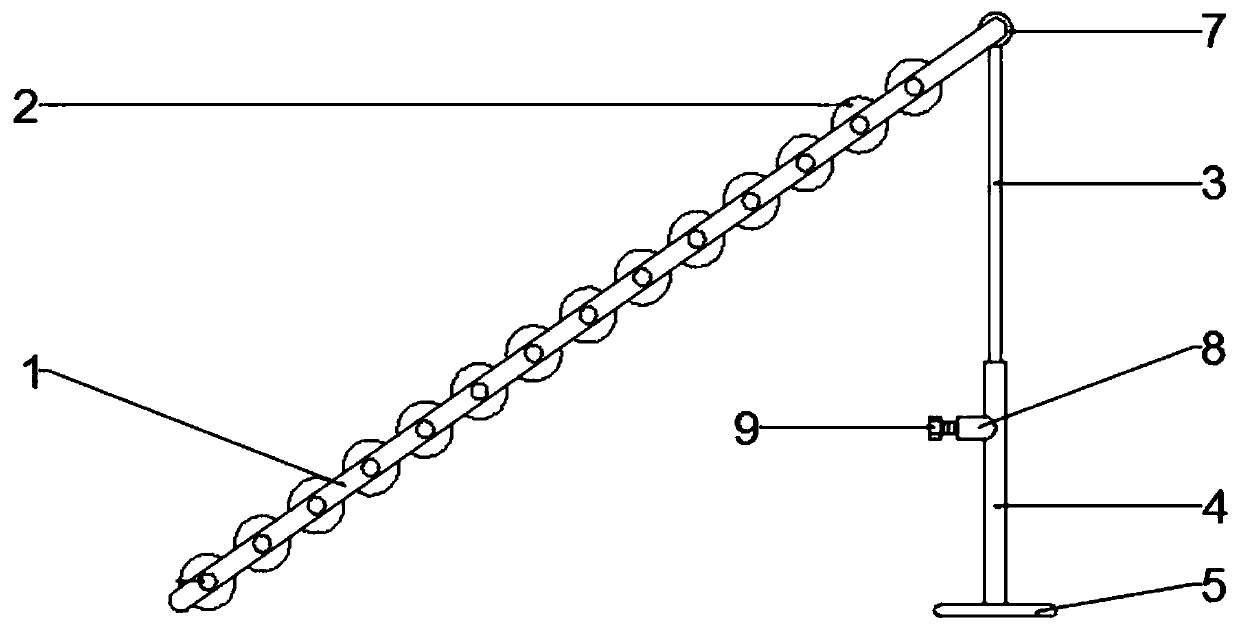

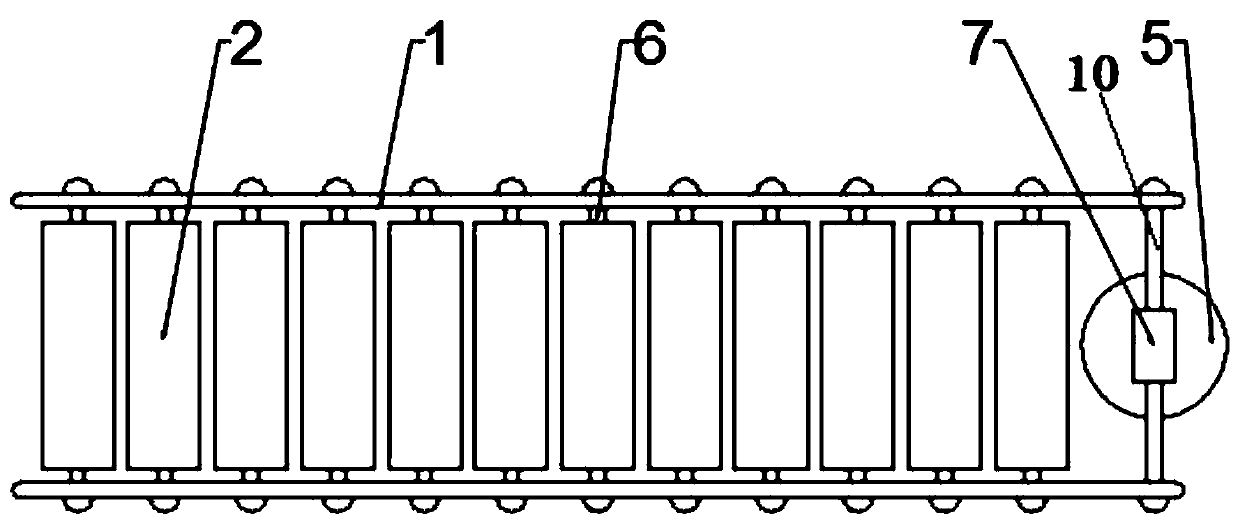

[0010] As shown in the figure, the truck body unloading rack includes: an auxiliary rod 1, a telescopic rod 3 and a base 5, the surface of the base 5 is provided with a welded support tube 4, the support tube 4 is a hollow cylinder, and the top surface is provided with Through holes, a threaded pipe 8 is provided in the middle of the support pipe 4, and the threaded pipe 8 is vertically connected with the support pipe 4. The threaded pipe 8 is provided with a bolt 9, and the bolt 9 cooperates with the threaded pipe. The support The tube 4 is provided with a telescopic rod 3, the bottom surface of the telescopic rod 3 is provided with a baffle plate, the diameter of the telescopic rod 3 is smaller than the through hole, and the diameter of the baffle plate is larger than the through hole, so as to prevent the telescopic rod 3 from breaking away from the support pipe 4, and the telescopic rod 3 3 The top surface is provided with a sleeve 7, the sleeve 7 is hollow cylindrical, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com