The three-beam intersection structure of steel box girder with single-box three-chamber section and manufacturing method thereof

A single-box three-chamber, steel box girder technology, applied in bridges, bridge parts, bridge construction, etc., to achieve the effect of improving structural reliability, reducing risks, and avoiding stress concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

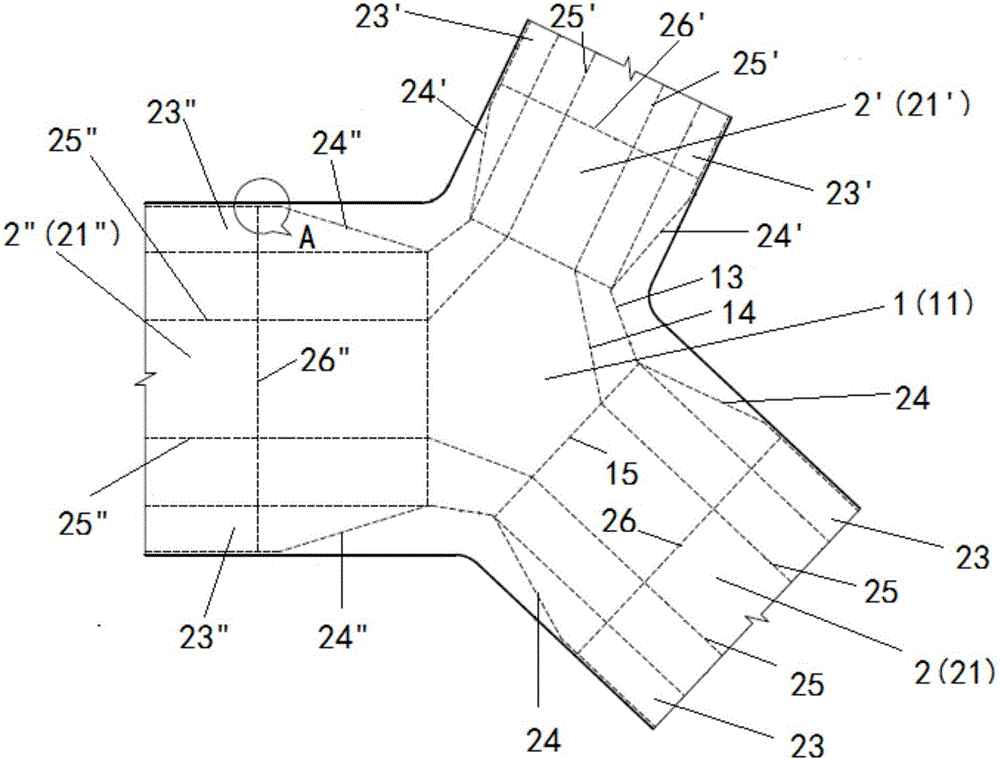

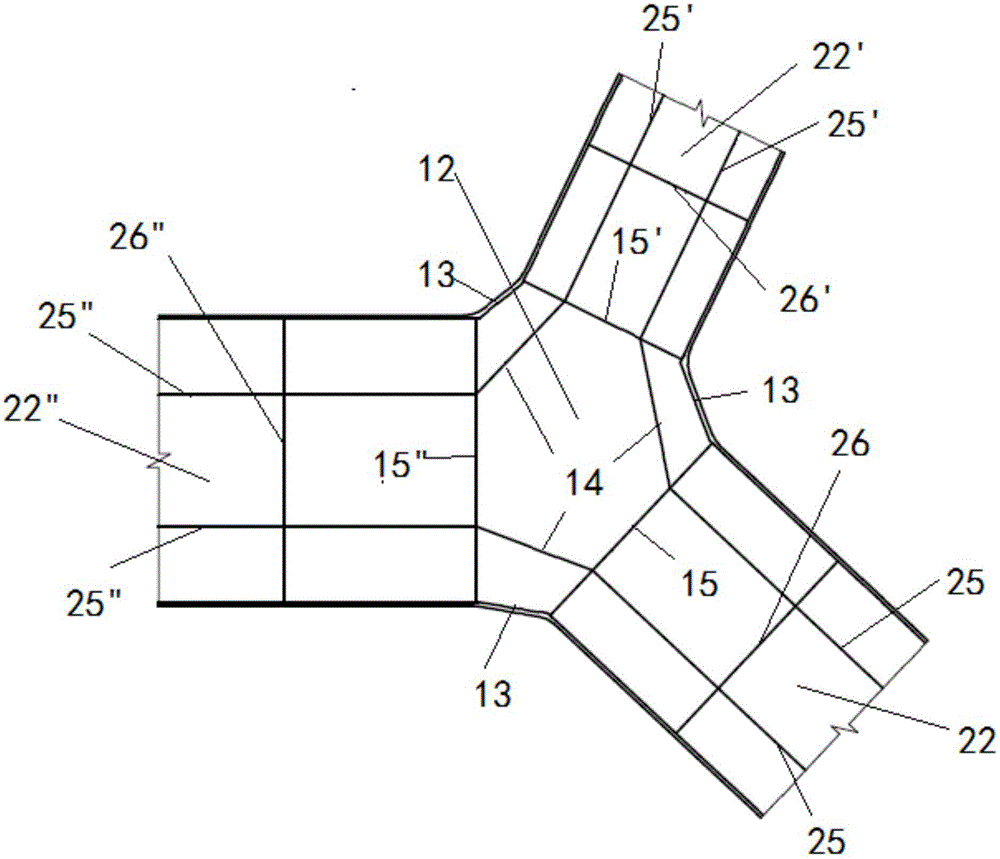

[0039] Such as figure 1 , Figure 4 ,and Figure 5 As shown, the three-girder intersection structure of steel box girder with single box and three-chamber section is adopted, including A, B, C three beams 2, 2', 2", A, B, C three beams 2, 2', 2" The angle between the planes is 90 to 120 degrees, and the three beams 2, 2', 2" of A, B, and C meet at node 1.

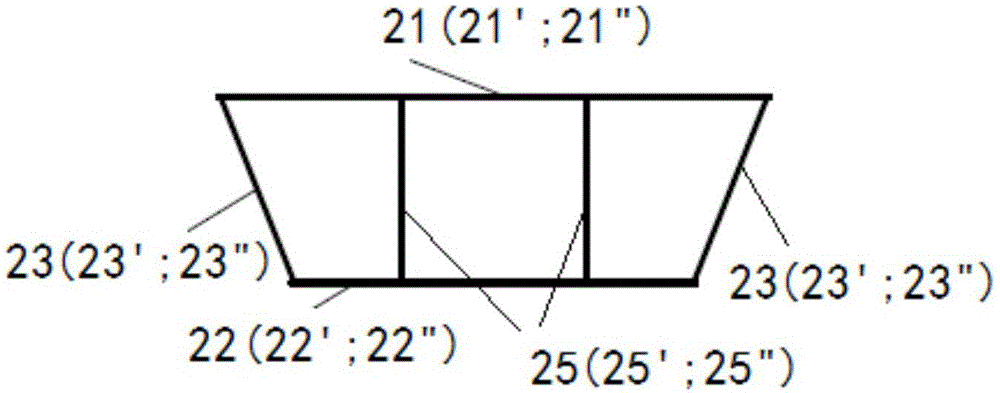

[0040] Such as figure 2 Shown, A, B, C three beams 2, 2 ', 2 " are respectively made up of A, B, C beam roof 21, 21 ', 21 ", A, B, C beam floor 22, 22 ', 22 ", A, B, C beam inclined web 23, 23', 23", A, B, C beam straight web 25, 25', 25", and A, B, C beam diaphragm 26, 26', 26 "Welded into a steel box girder with a trapezoidal cross-section.

[0041] Each beam is set separately: 1 roof, 2 inclined webs, 2 reinforced webs, 2 straight webs, 1 bottom plate, and several transverse partitions. The top plate and the bottom plate can be kept parallel to the geoid, or can have a certain angle with it. The top plate can be ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com