Pipeline power generating station

A technology for power stations and pipelines, applied to engine components, machines/engines, mechanical equipment, etc., can solve problems such as excessive loss and waste of clean energy, and achieve the effect of avoiding excessive loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

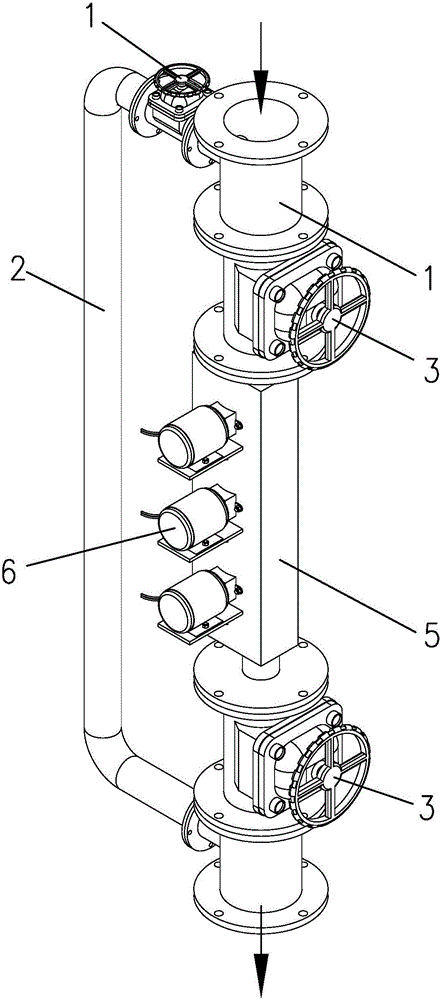

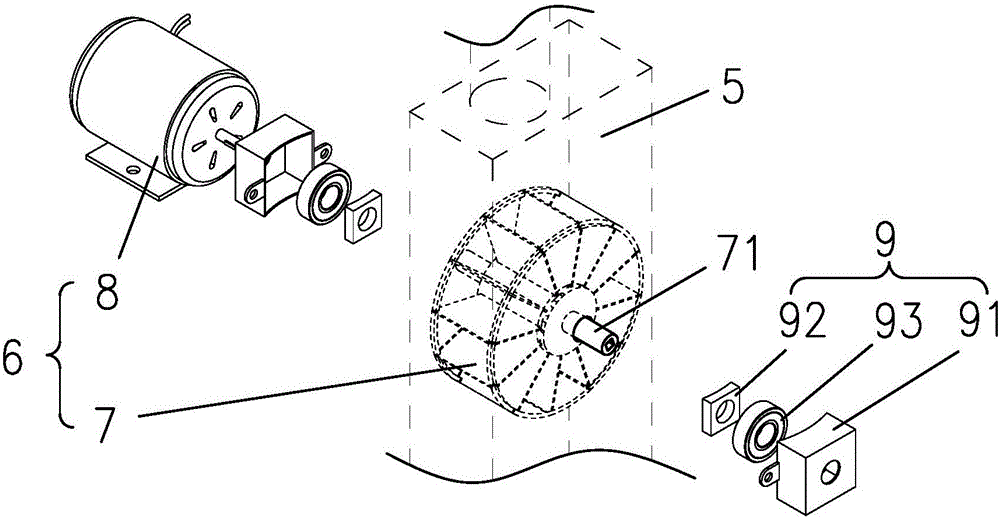

[0012] refer to figure 1 , figure 2 , a pipeline power station, comprising a main pipeline 1 and a secondary pipeline 2 connected in parallel to the fluid delivery pipeline, the two ends of the main pipeline 1 are provided with a normally open water valve 13, and the secondary pipeline is provided with a normally closed Water valve II 4; the main pipeline 1 is provided with a unit pipeline 5 connected between the two water valves I 3, and the unit pipeline 5 is provided with one or more sets of hydraulic generator sets 6.

[0013] Under normal working conditions, the water valve II 4 of the auxiliary pipeline 2 is in a closed state, and the fluid can only be transported through the main pipeline 1, so that the kinetic energy of the fluid itself is converted into electrical energy through the hydroelectric generator set 6; When the generator set 6 is being maintained or repaired, the two water valves 13 at both ends of the main pipeline 1 can be closed. If the water valve II...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com