Variable-buoyancy buoyancy tank and application thereof

A technology of buoyancy and buoyancy, which is applied in pipeline laying and maintenance, pipes/pipe joints/fittings, mechanical equipment, etc. It can solve the difficulty of long-distance pipe welding, the difficulty of entering large-scale crane ships, and high precision Require high-level problems to achieve the effect of ensuring welding quality, high precision, and convenient lifting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

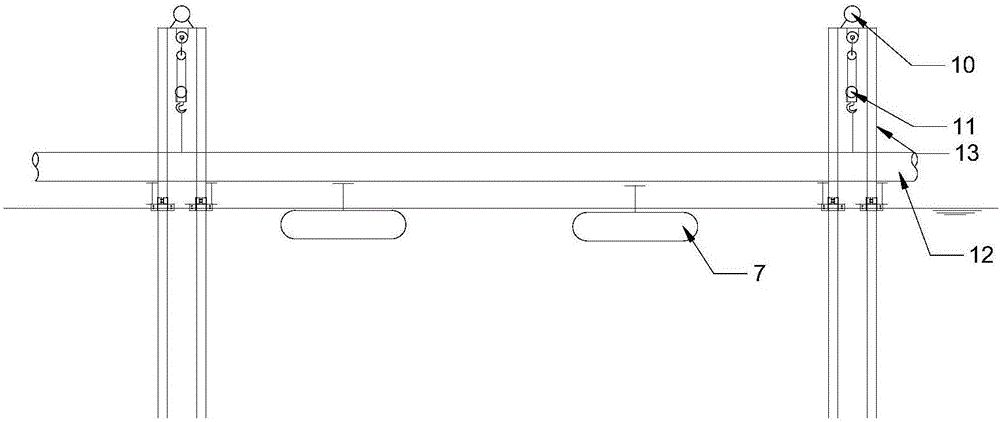

[0061] Preferred embodiments of the present invention will be specifically described below in conjunction with the accompanying drawings, wherein the accompanying drawings constitute a part of the application and are used together with the embodiments of the present invention to explain the principles of the present invention.

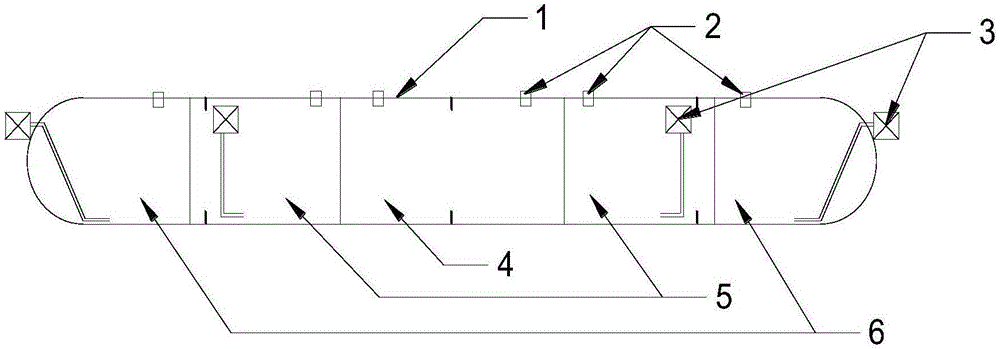

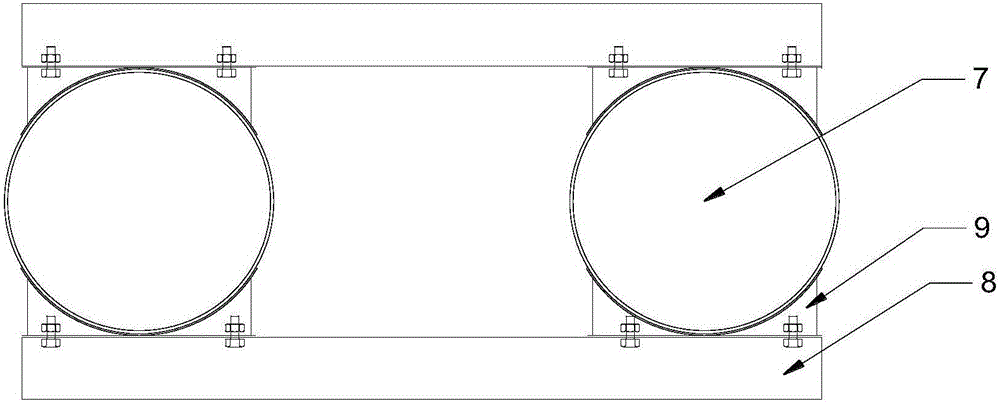

[0062] A buoyancy variable buoyancy tank, the buoyancy variable buoyancy tank comprises: a shell 1, an exhaust valve 2, and a water inlet valve 3;

[0063] The main body of the shell 1 is a steel pipe, the two ends of the shell 1 are hemispherical heads, and the cylindrical tube and the hemispherical head are sealed and connected by welding;

[0064] The interior of the shell 1 is divided into five mutually sealed chambers along the axial direction of the shell 1 through the compartment steel plate: the middle chamber is the main chamber 4, the two chambers at both ends are the second hydraulic chamber 6, and the remaining two The chambers are the seco...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com