Glue spraying device for shoemaking

A technology for spraying glue and shoes, applied in the direction of spraying device, etc., can solve problems such as time-consuming and inconvenient operation, and achieve the effect of saving cost, saving time and manpower, and overcoming time-consuming and inconvenient operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

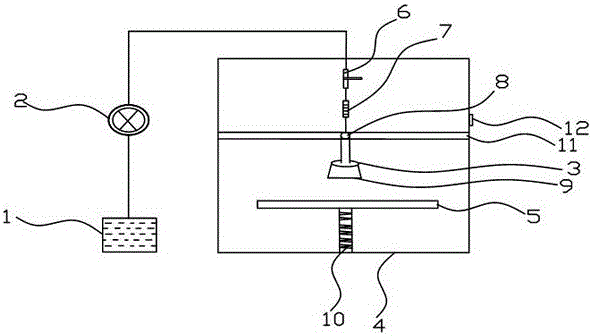

[0017] Such as figure 1 As shown, a glue spraying device for shoemaking provided by the present invention includes a liquid storage tank 1, a liquid pumping device 2, an operation box 4, a glue spray port 3 and a placement table 5, and the glue spray port 3 and the placement table 5 are placed In the operation box 4, the glue spray port 3 is located directly above the placement table 5, the liquid storage tank 1, the liquid pumping device 2 and the glue spray port 3 are connected in sequence through the infusion pipeline, the glue spray port 3 is a circular closed structure, and the circular closed There are a number of leakage holes on the structure, the circular closed structure is covered with a glue spray cover 9, a flow regulating valve 6 is arranged between the liquid pumping device 2 and the circular closed structure, a sliding rod 11 is arranged on the operation box 4, and a sliding rod 11 is installed on the sliding rod 11. Electric pulley 8, circular closed structure...

Embodiment 2

[0020] Based on Example 1, such as figure 1 As shown, the above-mentioned placing platform 5 is provided with a miniature hydraulic lift 10, and the miniature hydraulic lift 10 is fixed on the bottom of the operation box 4.

[0021] The miniature hydraulic lifter 10 can lower the placement table to a height suitable for the user to place the sample to be sprayed, which is convenient for the user to operate.

Embodiment 3

[0023] Based on Example 1, such as figure 1 As shown, a flow meter 7 is arranged between the above-mentioned flow regulating valve 6 and the circular closed structure.

[0024] The flow meter 7 is convenient for the user to read the flow rate of the glue, and it is convenient for the user to cooperate with the flow regulating valve 6 to control the amount of the glue, so that the glue can be used rationally to save costs.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com