A carbon dioxide cracker

A technology of carbon dioxide and cracker, which is applied in the direction of discharge machinery, mining equipment, earthwork drilling and mining, etc., and can solve problems such as unsatisfactory, inability to deploy equipment, and limited drilling space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

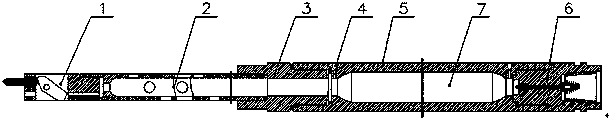

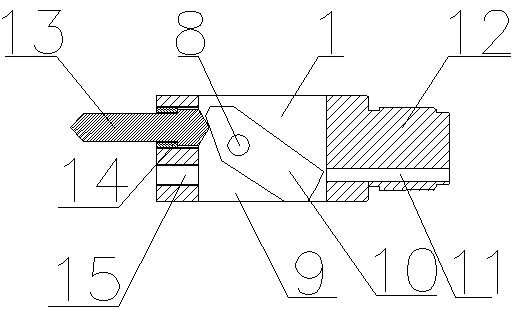

[0012] The present invention relates to a carbon dioxide cracker, which includes a liquid storage tube 5 with a hollow cavity 7, and the left and right ends of the liquid storage tube 5 are respectively provided with holes communicating with the hollow cavity 7 of the liquid storage tube 5. Fill the exhaust port 4, the connecting end on the right side of the liquid storage tube 5 is provided with a heating tube extending into the hollow cavity 7 of the liquid storage tube 5, and the connecting end on the right side of the liquid storage tube 5 is connected to a The filling valve 6 is connected, and the connecting end on the left side of the liquid storage pipe 5 is connected with a release pipe 3, and the release channel of the release pipe 3 communicates with the hollow cavity 7 of the liquid storage pipe 5, and the release pipe The left side of 3 is provided with a connecting end with an internal thread, and a hollow gun rod 2 is screwed on the internal thread of the connecti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com