Leak detection machine of paper cup (bowl) machine

A detection machine and detection mechanism technology, which can solve the problems of unqualified paper cups or paper bowls, easy leakage, leakage, etc. Achieving significant progress, various detection methods, and highlighting the effect of substantive features

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

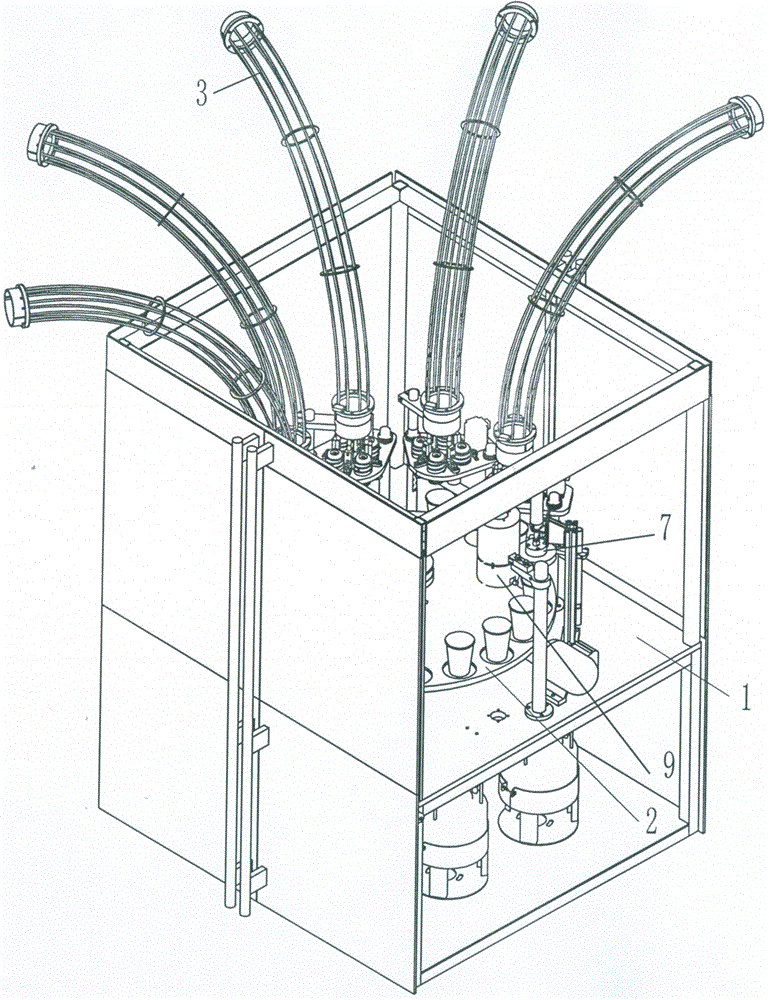

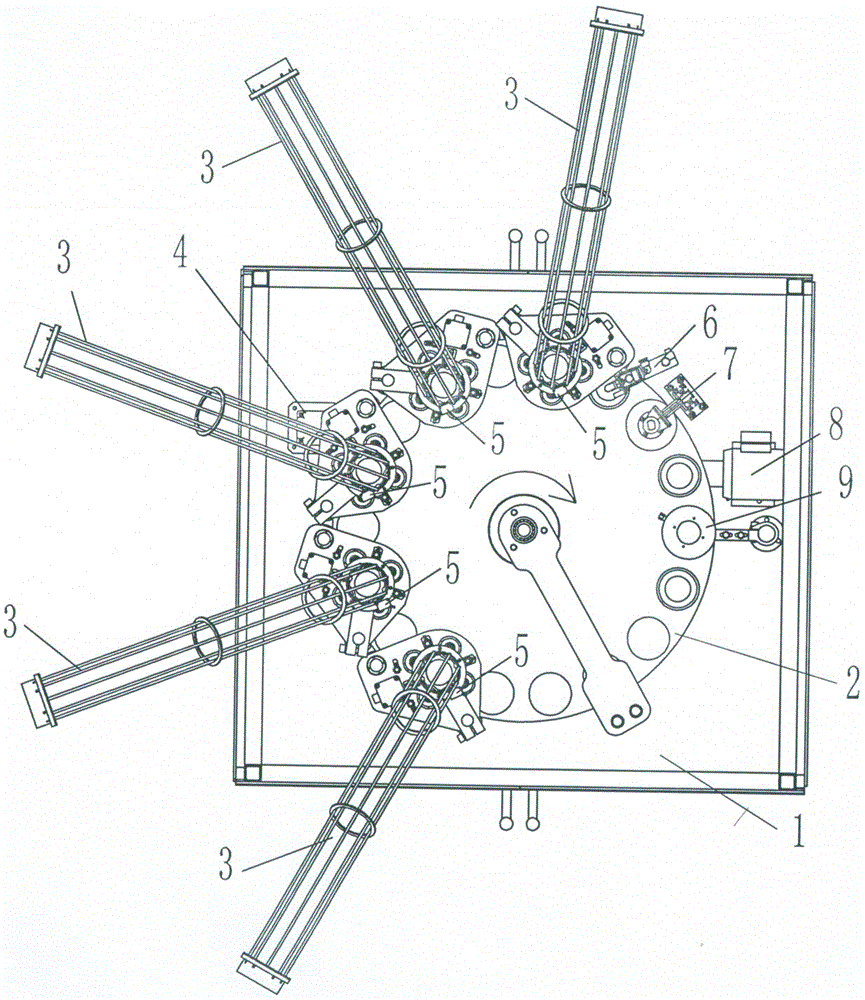

[0018] Referring to the accompanying drawings, the paper cup (bowl) machine leak detection machine in this embodiment is used to detect whether the paper cup or paper bowl leaks, leaks, or seeps. It can be used on-line with paper cup or paper bowl production equipment for sampling inspection of paper cups or paper bowls.

[0019] The paper cup (bowl) machine leak detection machine includes a frame 1, a rotating disk 2, a transmission device, a lower cup conveying channel 3 and a detection mechanism. The rotating disk 2 is driven by the transmission device to rotate on the frame, such as figure 1 The turntable rotates in a clockwise direction. The rotating disk is provided with a cup receiving device, and the lower cup conveying channel 3 is connected with the cup receiving device, and the cup receiving device is used to receive the paper cup or paper bowl coming out of the lower cup conveying channel. Conveying cage or conveying pipe, its outlet is towards the rotating disk ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com