Test method for specimens suitable for measuring film material constants by ultrasonic resonance spectroscopy

A thin film material and testing method technology, which is applied in the direction of using sound wave/ultrasonic wave/infrasonic wave to analyze solids, etc., can solve problems such as difficult and impossible to measure the film material constant, and achieve the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

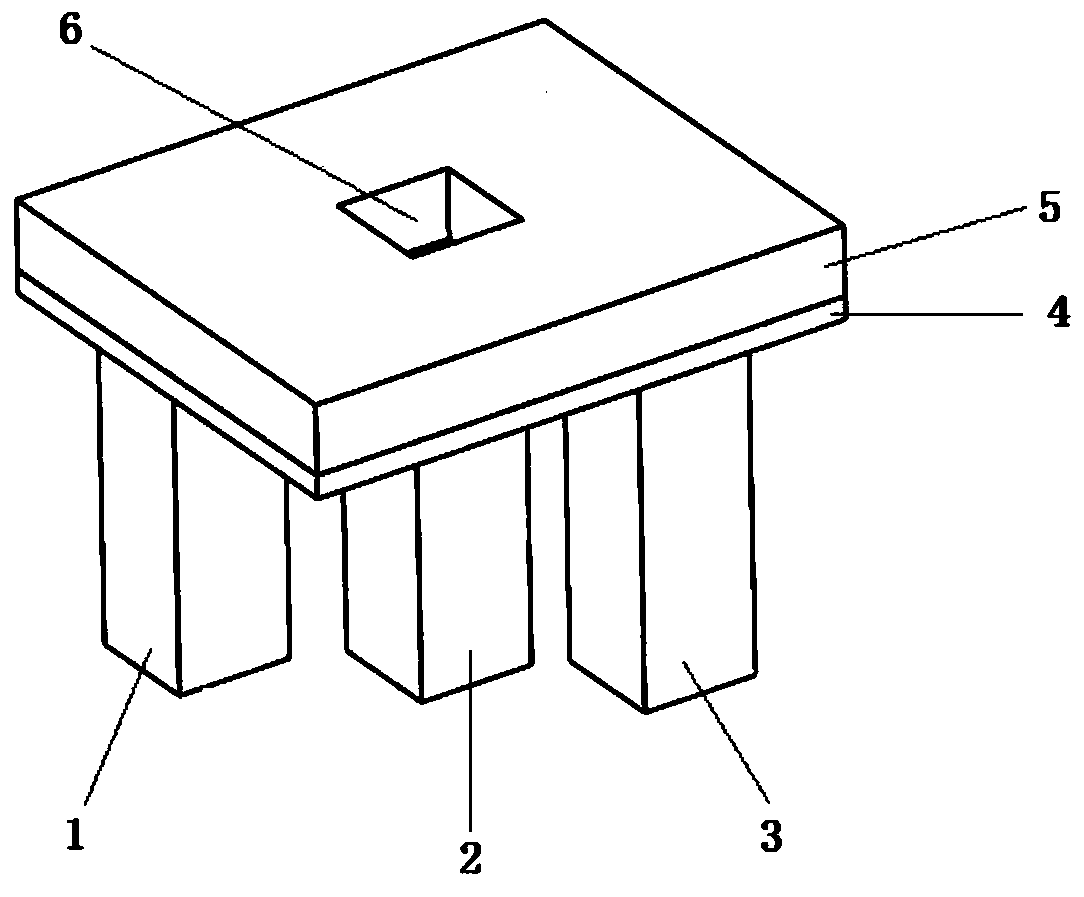

[0044] Such as figure 2 As shown, the acoustic resonance spectroscopy method measures the sample of the material constant of the film, including the substrate, the film and the corrosion hole.

[0045] The film is 20×24mm 2 Sc 0.4 Al 0.6 N film with a thickness of 1 μm. The substrate is SiC with known material constant, and the thickness is 0.5mm. The small hole mentioned is that the bottom surface is 6×5mm 2 A rectangular truss with an angle of 53° between the sides and the bottom, a height of 0.35 mm, and the center coincides with the center of the base.

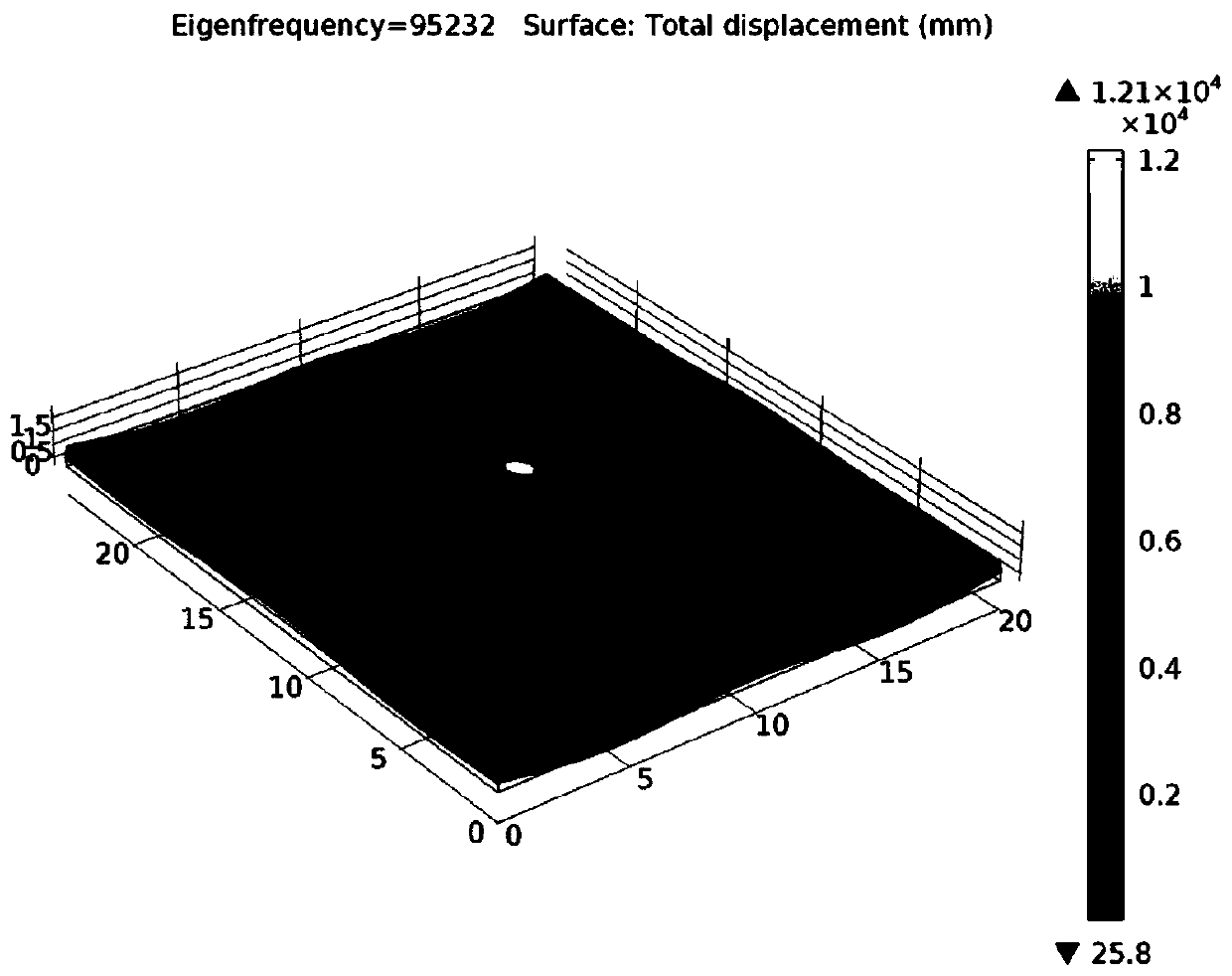

[0046] The film side of the sample is placed downwards, and is lifted up by three transducers, and the end surface area of the transducers is 5×5mm 2 , in the figure, the receiving transducer is placed at the thin film corresponding to the small hole, because the amplitude here is the largest. The data of the first receiving transducer and the second receiving transducer are fused with each other, which can reduc...

Embodiment 2

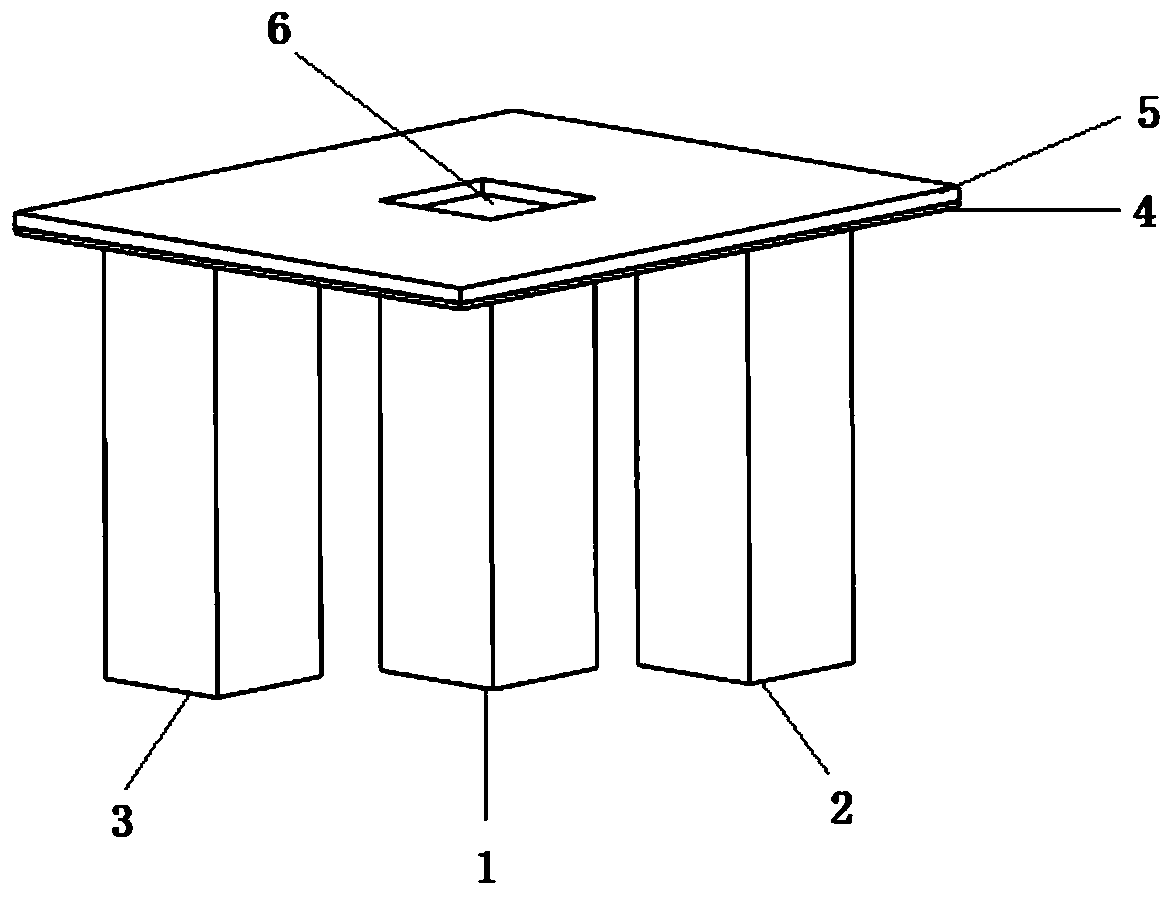

[0050] Such as Figure 4 As shown in Fig. 1, the sample of thin film material constant measured by acoustic resonance spectroscopy includes substrate, thin film and two corrosion holes.

[0051] The film is 20×24mm 2 Sc 0.4 al 0.6 N film with a thickness of 1 μm. The substrate is SiC with known material constant, and the thickness is 0.5mm. There are two small holes, both of which are 5×6mm 2 through-holes, the centers of which are respectively located at the right 1 / 3 of the substrate.

[0052] The sample film is placed downwards and lifted up by three transducers, and the end surface area of the transducers is 5×5mm 2 , in the figure, the receiving transducer is placed at the thin film corresponding to the small hole, because the amplitude here is the largest. The data of the first receiving transducer and the second receiving transducer are fused with each other, which can reduce the influence of a certain transducer modal measurement loss on the whole.

[0053] T...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com