Interlayer gravity support device for magnetic shielding room

A support device and magnetic shielding technology, which is applied in the direction of magnetic field/electric field shielding, projection room/room, electrical components, etc., can solve the problems of shielding performance decline and magnetic permeability decline in shielding rooms, and achieve high reliability and convenient installation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

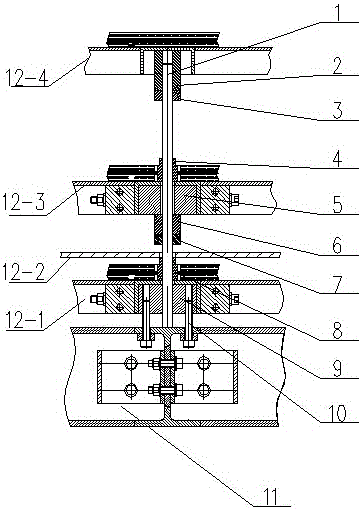

[0023] Depend on figure 1 As can be seen from the shown embodiment, it includes a support screw 1, two sets of adjusting sleeves (adjusting sleeve I2 and adjusting sleeve II6), two sets of locking sleeves (locking sleeve I4 and locking sleeve II8) , Two sets of lock nuts (lock nut I3 and lock nut II7), two sets of load-bearing pads (load-bearing pad I5 and load-bearing pad II9) and a set of lock bolts 10. Two sets of adjustment sleeves (adjustment sleeve I2 and adjustment sleeve II6) are installed on the support screw 1 as the load-bearing nodes of the shielding layer, and the weight of each shielding layer inside is adjusted through the support screw 1 passing through the shielding layer. Transferred to the installation platform 11, the outermost shielding layer support node is the load-bearing pad II9; the load-bearing node is respectively formed by the two sets of locking sleeves and the Two sets of locking nuts are locked to ensure the reliability of the load-bearing node...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com