Sewage collecting and discharging process of flowing water breeding tank

A breeding tank and flowing water technology, which is applied in the sewage discharge field of running water breeding tanks, can solve the problems of poor sewage collection and sewage discharge, and achieve the effects of good sewage discharge effect, convenient implementation, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

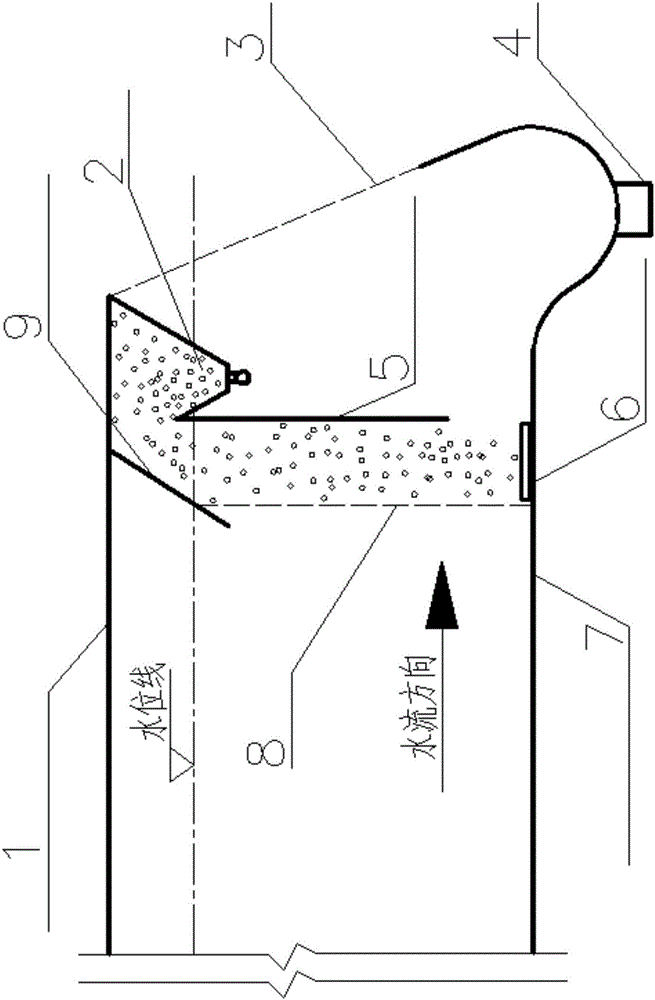

[0022] see figure 1 , a kind of flowing water aquaculture tank collection and sewage discharge process, the upper part of the fish blocking net 8 at the end of the flowing water aquaculture tank is obliquely provided with a foam deflector 9 and the lower end extends to the water surface, and the first sewage collecting tank is arranged behind the foam deflector 9 2, the upper end is higher than the water level line (10-15cm) and the gas-liquid separation partition 5 with a certain distance (50-60cm) from the lower end to the bottom surface of the running water culture tank is set below the first collection tank 2; the bottom plane of the running water culture tank is at 7 The position of the nano-aeration disc 6 is extended backwards with a sunken buffer zone, the bottom of the buffer zone is provided with a second sewage collection tank 4, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com