A fender structure for a vehicle and an assembly method thereof

An assembly method and fender technology are applied in the field of fender structures, which can solve the problem of high manufacturing cost of fenders, achieve the effects of stable and reliable performance indicators, reduce vehicle body weight, and meet modeling and structural design requirements.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

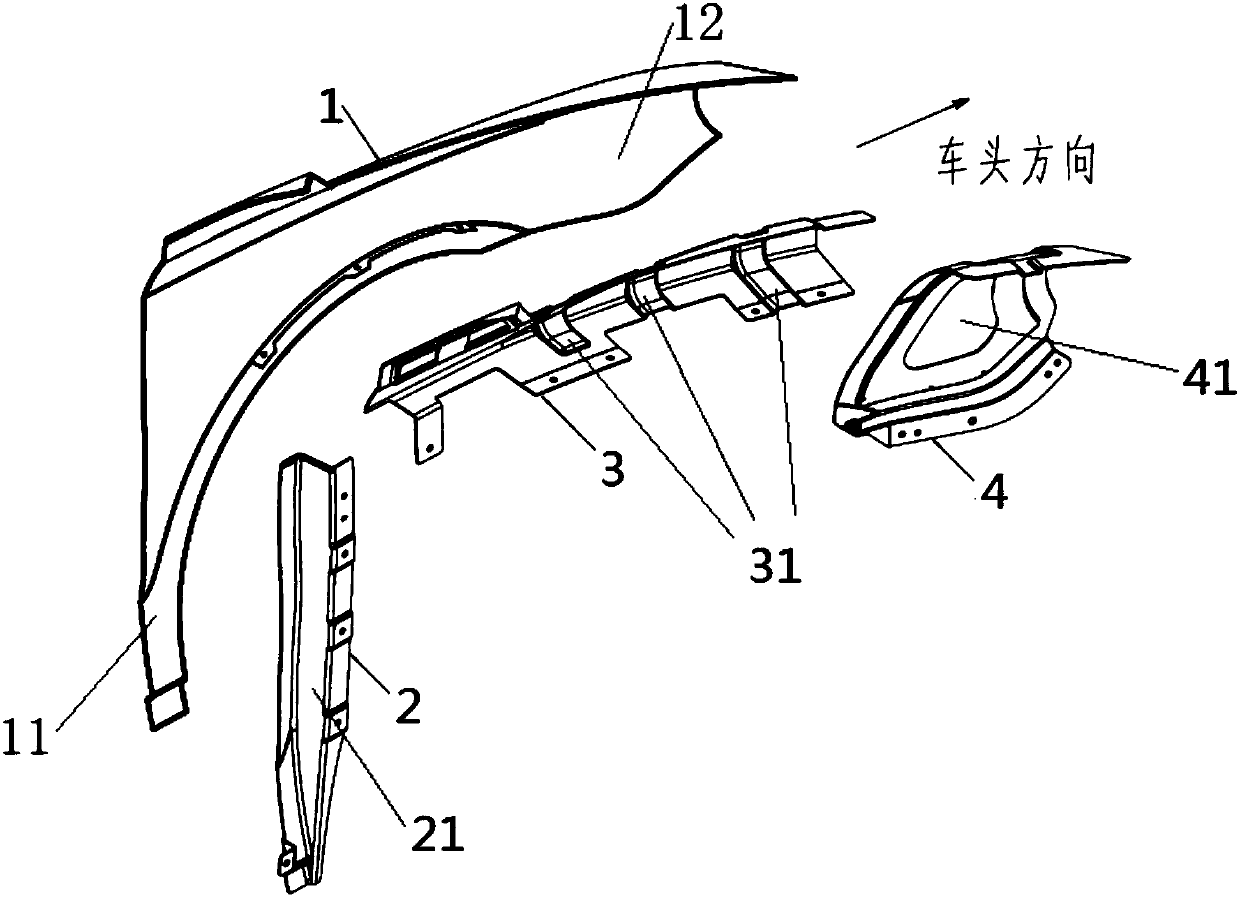

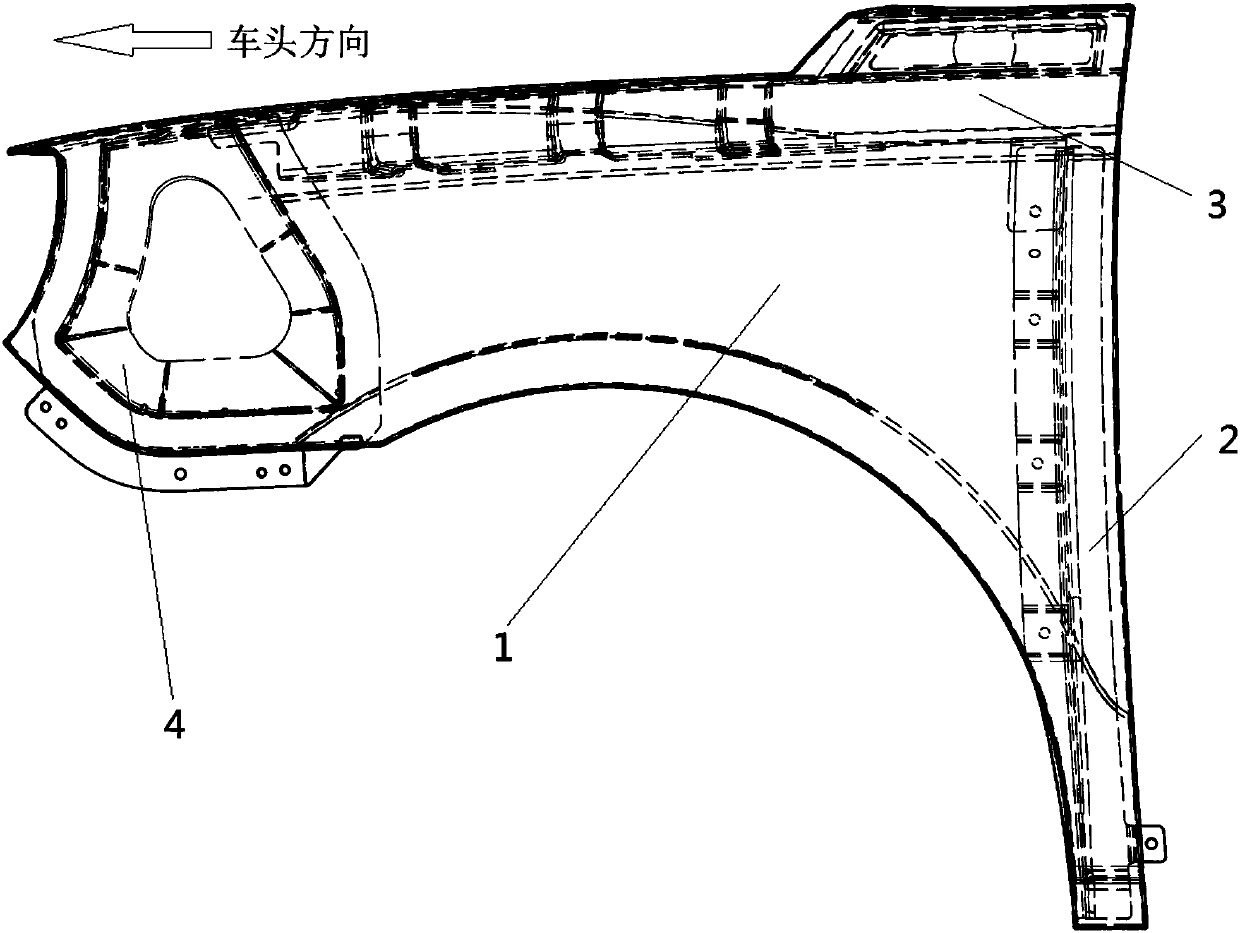

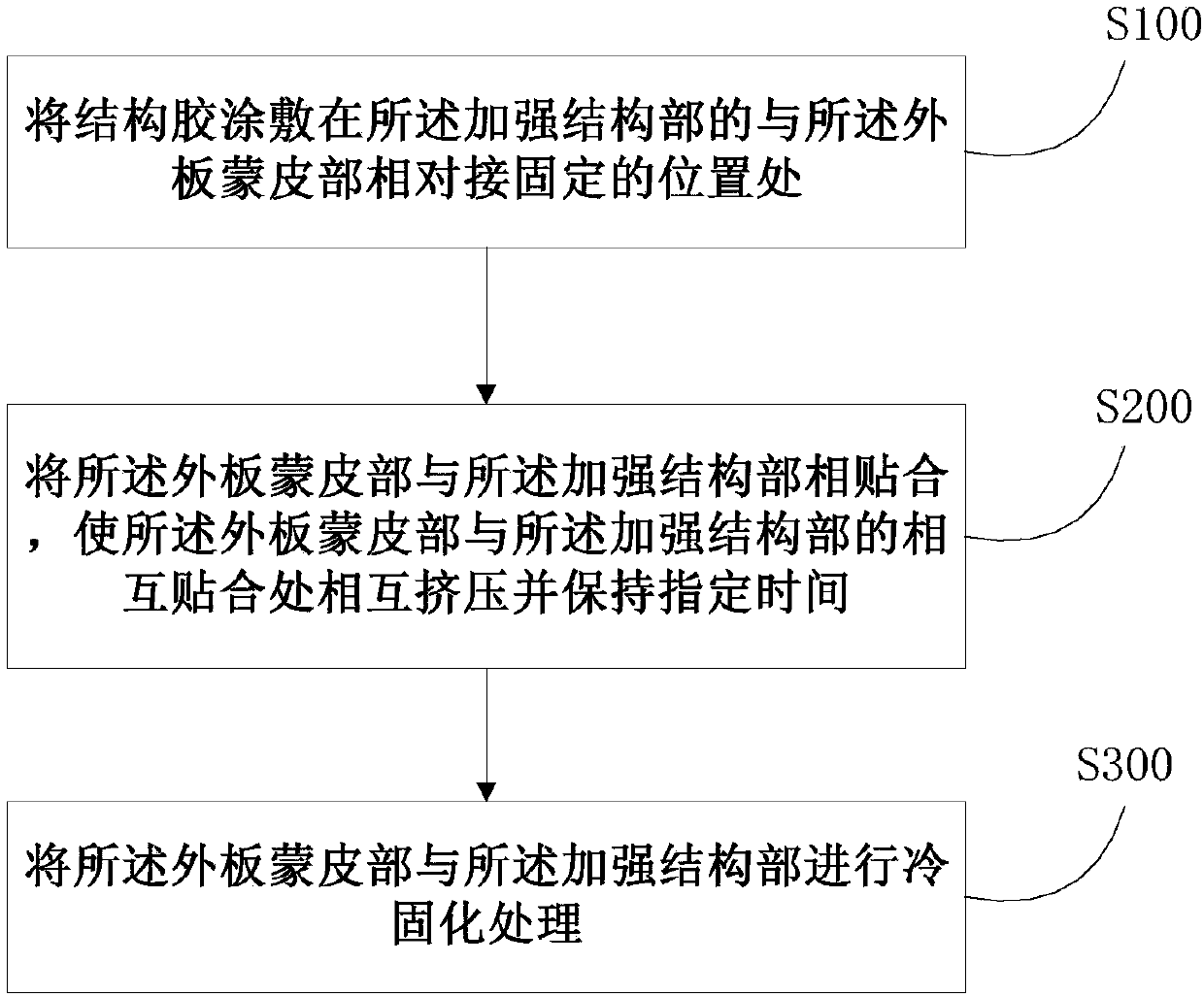

[0035] figure 1 is a schematic exploded perspective view of the fender structure for a vehicle according to an embodiment of the present invention. figure 2 It is a schematic front view of the fender structure for a vehicle viewed from the outside of the outer panel skin portion toward the interior of the vehicle. Generally, the fender structure for vehicles may include: an outer panel skin part 1 and a reinforcement structure part (see figure 1 2, 3, 4).

[0036] The outer panel skin part 1 is used to cover the wheels of the vehicle, and the outer panel skin part 1 is made of SMC material and is molded. The reinforcing structure part is used to enhance the mechanical properties of the outer panel skin part 1, and it is formed on the inner side of the outer panel skin part 1, and the inner side of the outer panel skin part 1 is the outer panel skin part. The side of the leather part 1 facing the vehicle body, the reinforcement structure part is made of SMC material and is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com