Spoiler mounting structure

A technology for installing structure and spoiler, applied in the direction of streamlined body, transportation and packaging, body, etc., can solve the problems of dimensional tolerance of sealing strip, unstable installation, easy water leakage, etc., to achieve uniform internal stress, uniform force, The effect of size control improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

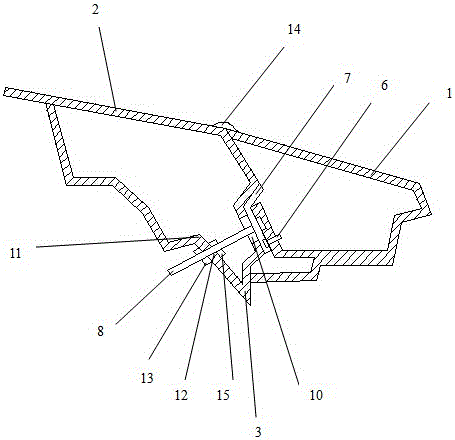

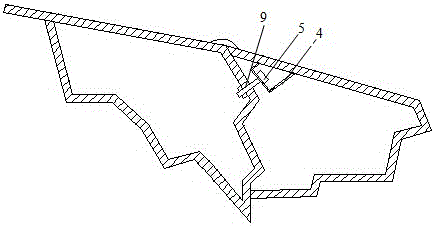

[0018] A spoiler installation structure, such as figure 1 figure 2 As shown, it includes a spoiler 1, a back door sheet metal 2, and a rear windshield 3. The upper end of the spoiler 1 is trimmed with a sealing strip 14, and the two ends of the spoiler 1 are fixed by a clip 4. There are square head bolts 5, and the middle of the spoiler 1 is fixed with a mounting bracket 7 through a reed nut 6. The mounting bracket 7 is welded with two long bolts 8, and the long bolts 8 are screwed at 1 / 3 of the free end. Square head nuts 15 are welded, and the two ends of the back door sheet metal 2 are provided with round holes 12 and waist-shaped holes 9 corresponding to the positions of the square head bolts 5 at both ends of the spoiler 1, and the middle of the back door sheet metal 2 is provided with The locking groove 10 corresponding to the position of the mounting bracket 7, the contact surface between the mounting bracket 7 and the locking groove 10 is provided with a waterproof pa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com