Dual bolt type veneer mounting structure and system

A technology for installing structures and decorative panels, which is applied in building construction, covering/lining, construction, etc. It can solve problems such as large installation errors, difficulty in ordering dimensions, and difficulty in construction and installation, and achieve the effect of precise installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

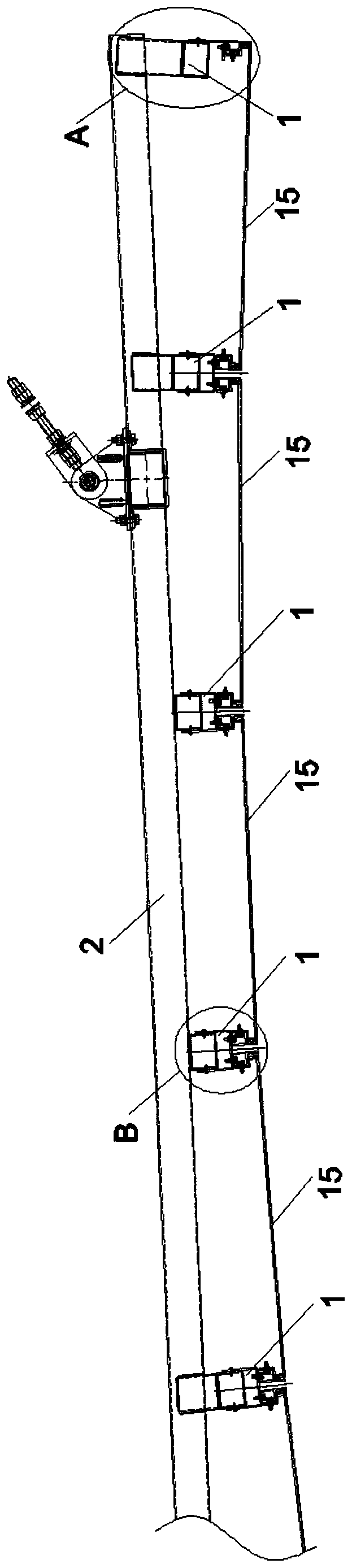

[0020] figure 1 It is a schematic diagram of the structure of the two-bolt veneer installation system in the embodiment.

[0021] like figure 1 As shown, in this embodiment, a two-bolt veneer installation system includes a main keel 2 and several two-bolt veneer installation structures 1 . The fixed skeleton 11 in the two-bolt veneer installation structure 1 is welded and fixed to the installation main keel 2 according to the position and angle required by the design. The installation main keel 2 may be a beam structure of a building or other auxiliary supports.

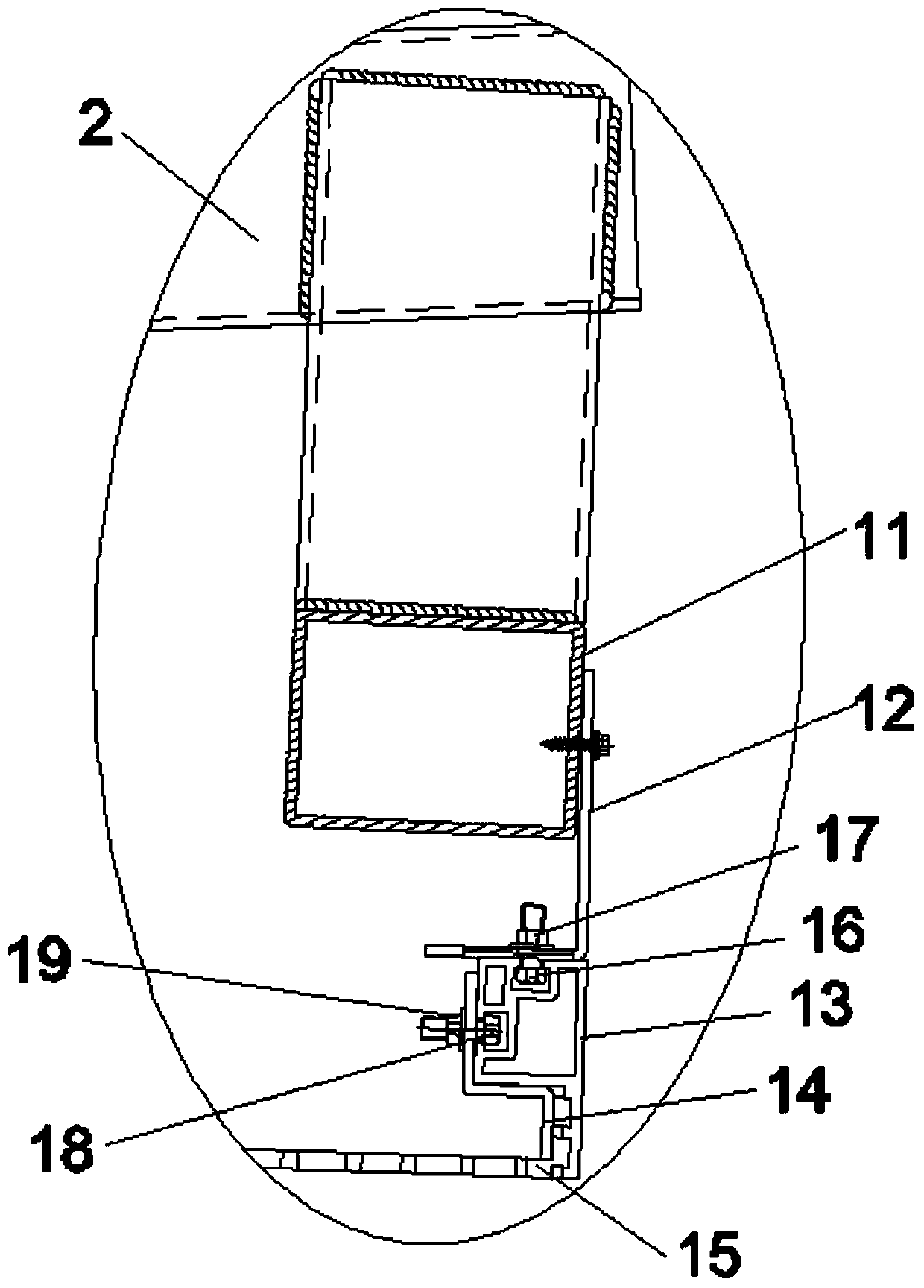

[0022] figure 2 Yes figure 1 An enlarged view of the two-bolt veneer mounting structure at position A in .

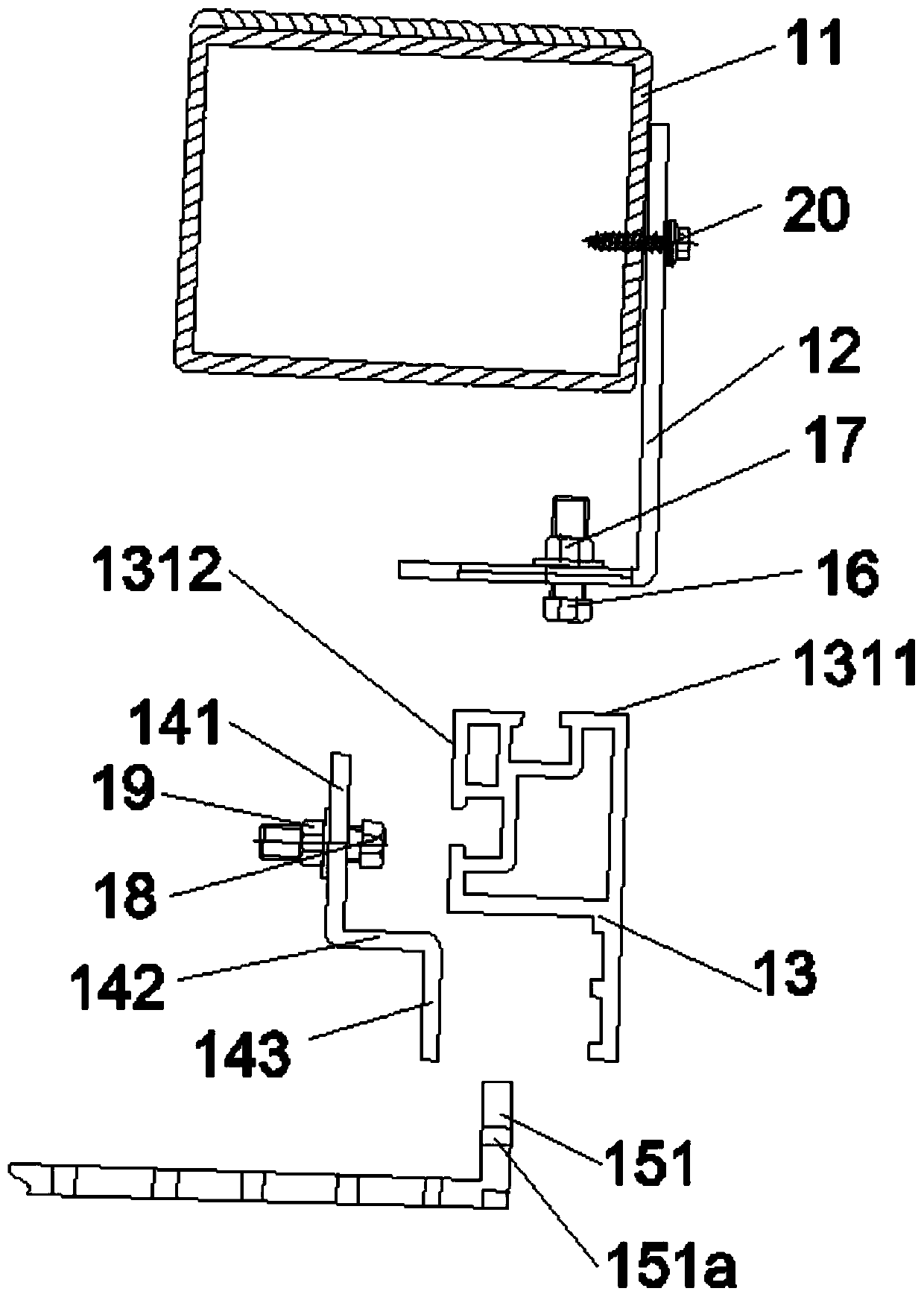

[0023] image 3 Yes figure 2 An exploded view of the two-bolt veneer mounting structure in .

[0024] like figure 2 and image 3 As shown, in the two-bolt veneer ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com