Supporting and hanging device for mounting newly-built coke oven protection plate

A suspension device and protection plate technology, which is applied in the directions of transportation and packaging, load suspension components, etc., can solve the problems that the installation quality of the protective furnace iron parts affects the service life of the coke oven production environment, the large number of parts, and the high installation technical requirements. The installation and construction are easy to operate, ensure the installation quality, and the effect of accurate installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Steps:

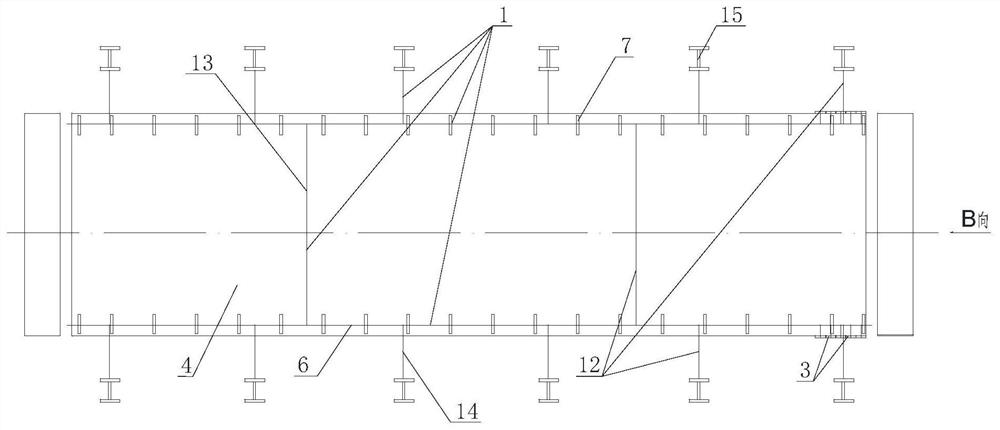

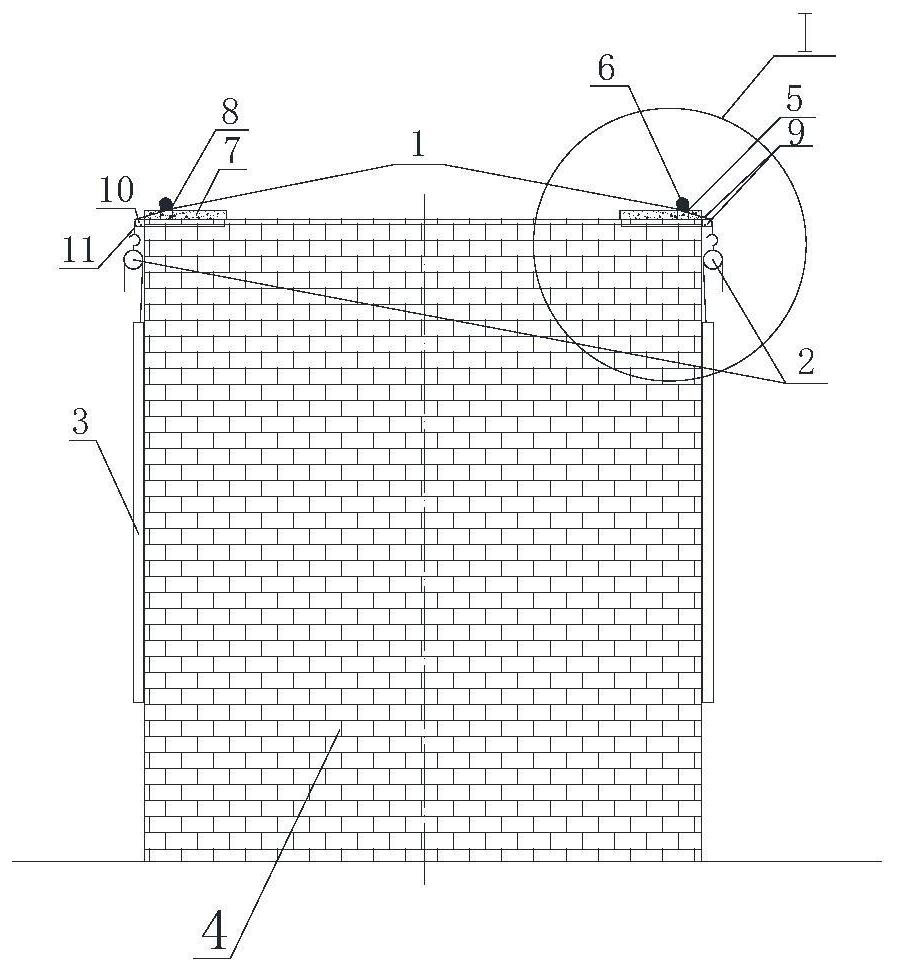

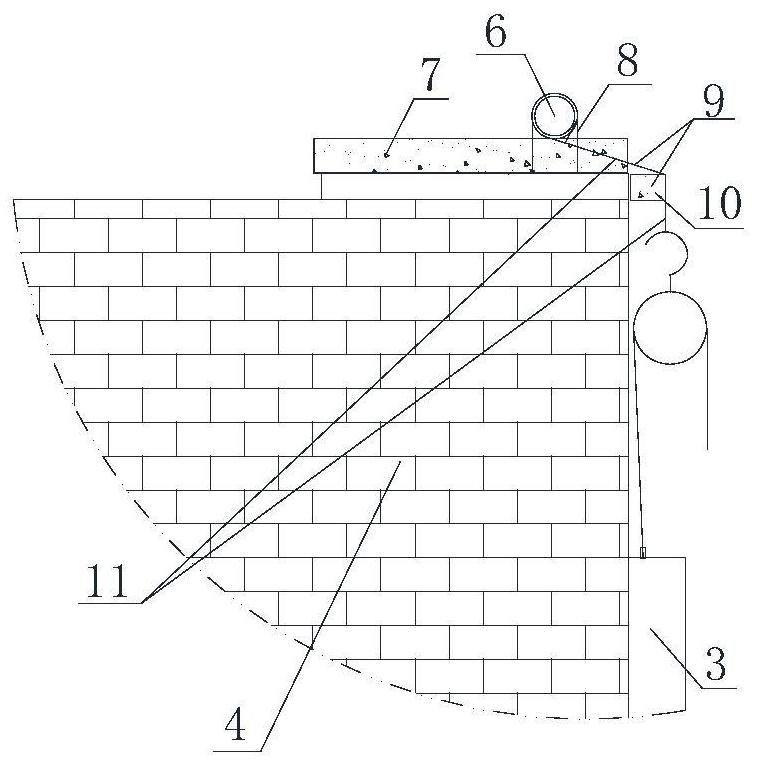

[0028] 1) After the masonry of the coke oven body is completed, set up a protective temporary suspension fixing frame on both sides of the machine and coke on the top of the coke oven. To protect the masonry of the furnace body, a seamless steel pipe D159×4 is added between the long seamless steel pipes on both sides of the coke to increase the stability of the fixing frame. In order to increase the stability of the hanging fixing frame, D159×4 is also used The seamless steel pipes are supported on the columns of the temporary greenhouse.

[0029] 2) From both sides of the coke, the protective plate is manually moved to the installation position with a mobile trolley, and then hoisted by a 10t crane installed in the greenhouse, and the chain hoist is used to connect with the temporary fixing frame, and the protective plate is temporarily suspended and fixed. The chain hoist is used to facilitate the installation and adjustment of the protection board.

[0030...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com