Rolling package appearance detection method and rolling package appearance detection apparatus

A technology of appearance inspection and roll packaging, which is applied in the direction of measuring devices, optical devices, transportation and packaging, etc., can solve the problems of heavy labor and achieve the effect of overcoming heavy labor and reducing the labor burden of workers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

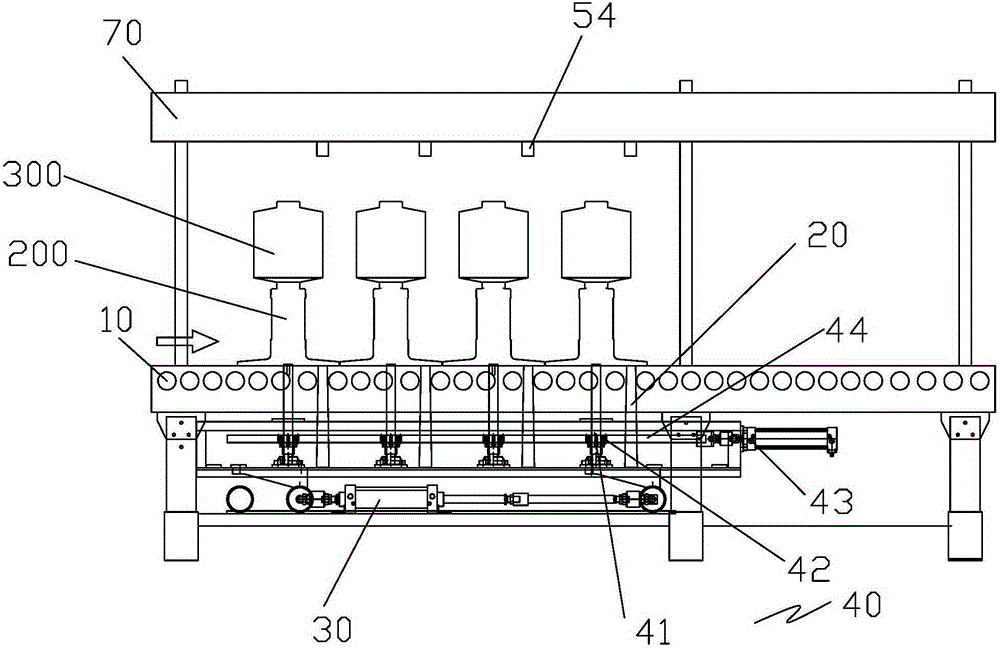

[0065] The technical solution of the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments to further understand the purpose, solution and effect of the present invention, but it is not intended to limit the scope of protection of the appended claims of the present invention.

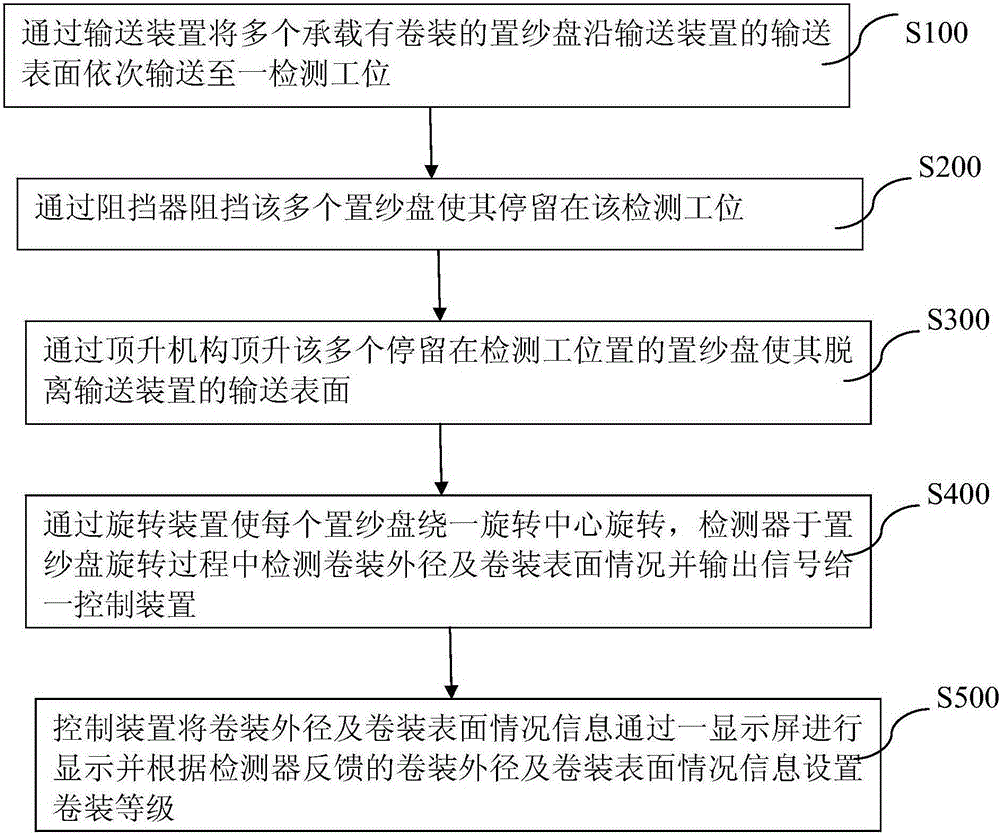

[0066] refer to figure 1 , as shown in the figure, the packaging appearance detection method of the present invention comprises steps:

[0067] S100, using a conveying device to sequentially convey a plurality of yarn loading trays carrying packages to a detection station along the conveying surface of the conveying device;

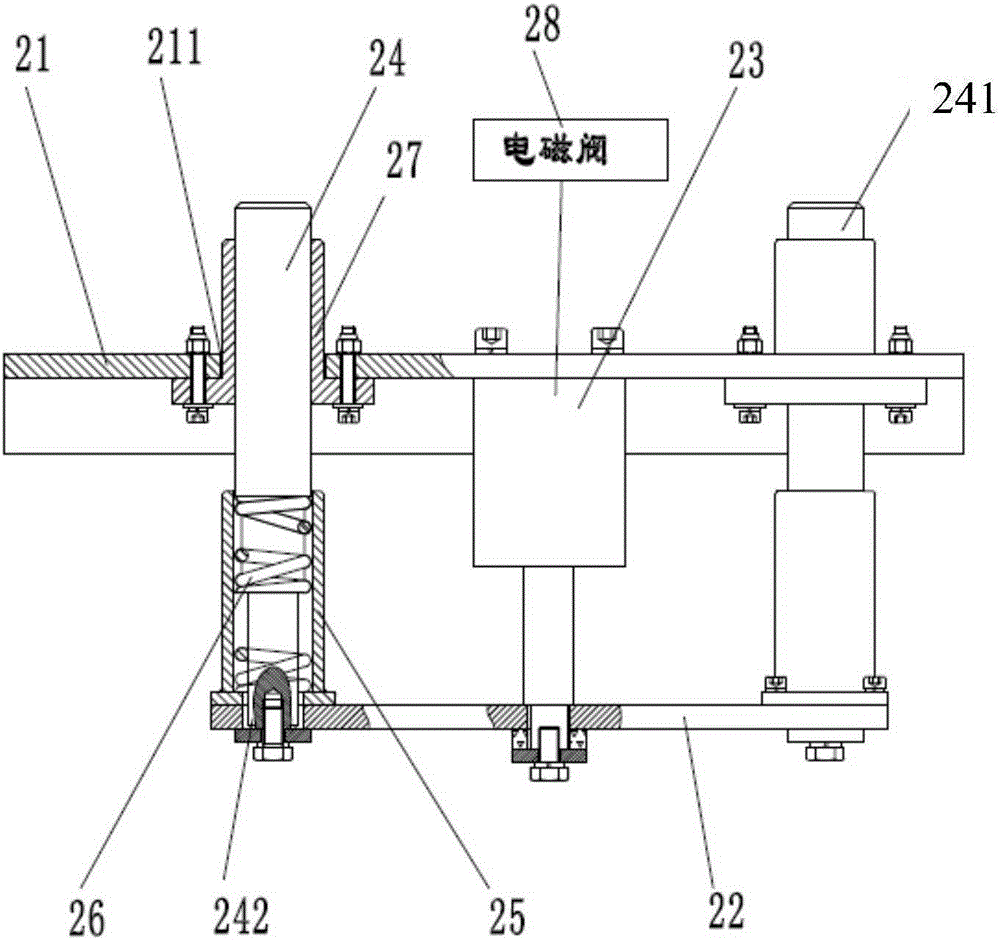

[0068] S200, blocking the plurality of yarn setting discs by a stopper so that they stay at the detection station;

[0069] S300, using a jacking mechanism to jack up the plurality of yarn setting discs that stay at the position of the inspector to separate from the conveying surface of the conveying device;

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com