Continuous freezing crystallizer and scar removing method thereof

A frozen crystallizer and crystallizer technology, applied in the direction of solution crystallization, etc., can solve the problems of not having scarring prevention and scarring removal, and achieve the effect of overcoming the impact of small output, large output, and reduced equipment capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

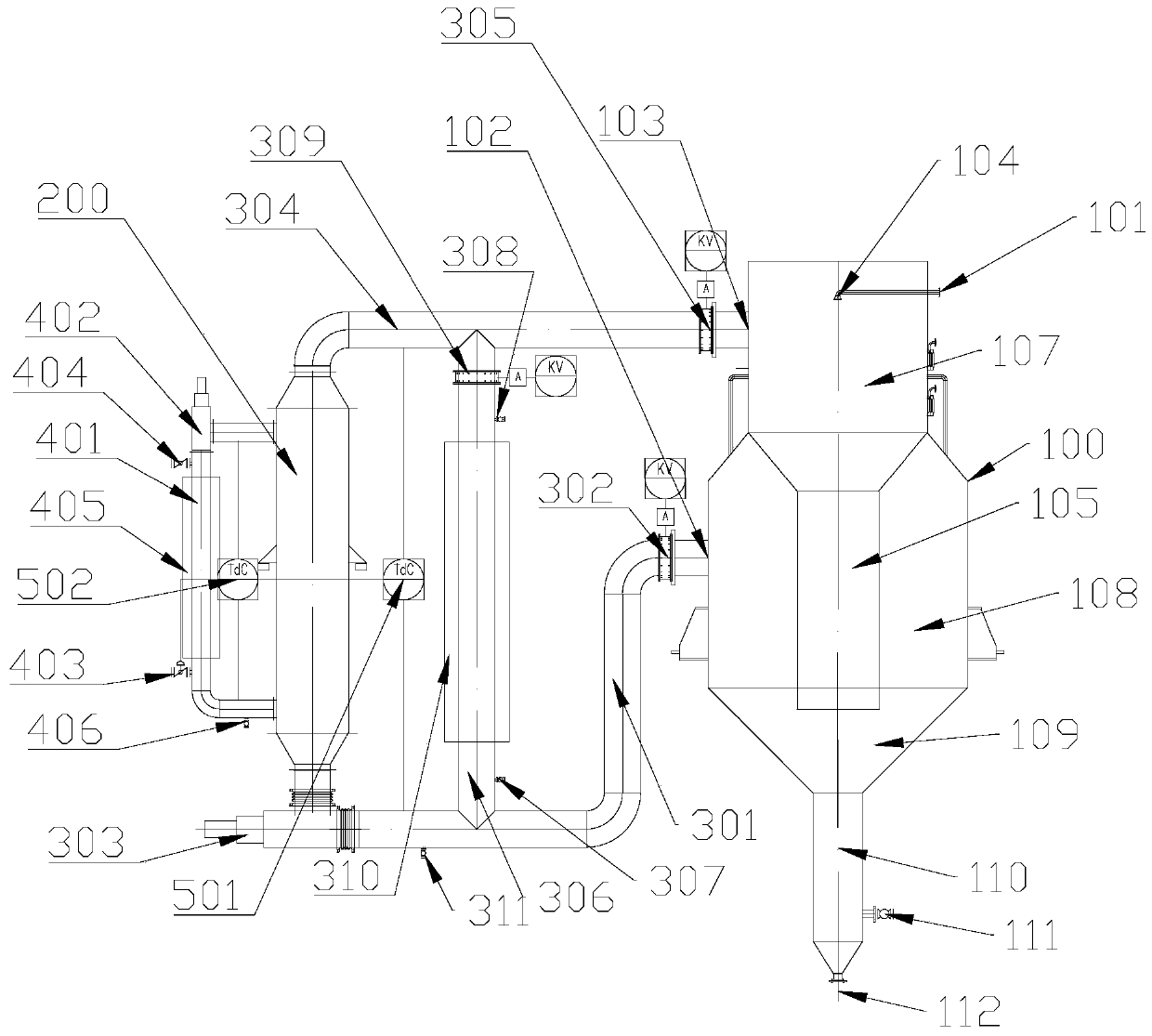

[0042] Such as figure 1 As shown, the continuous frozen crystallizer of the present invention includes a crystal grower 100, an external cooler 200, a material circulation system 300, a refrigerant circulation system 400 and a temperature control system;

[0043] The crystal grower 100 comprises a feed mixing section 107, a supernatant liquid settling section 108 and a magma classification section 109 interconnected from top to bottom, and a downcomer 105 is also provided in the crystal grower 100, and the downcomer 105 The upper end communicates with the feed mixing section 107, and the lower end extends into the magma classification section 109 and communicates with the magma classification section 109; the crystal grower 100 is provided with a raw liquid feed port 101, a circulation outlet 102, and a circulation loop. Feed port 103; stoste feed port 101 is arranged on feed mixing section 107, and circulation discharge port 102 is arranged on clear liquid settlement section ...

Embodiment 2

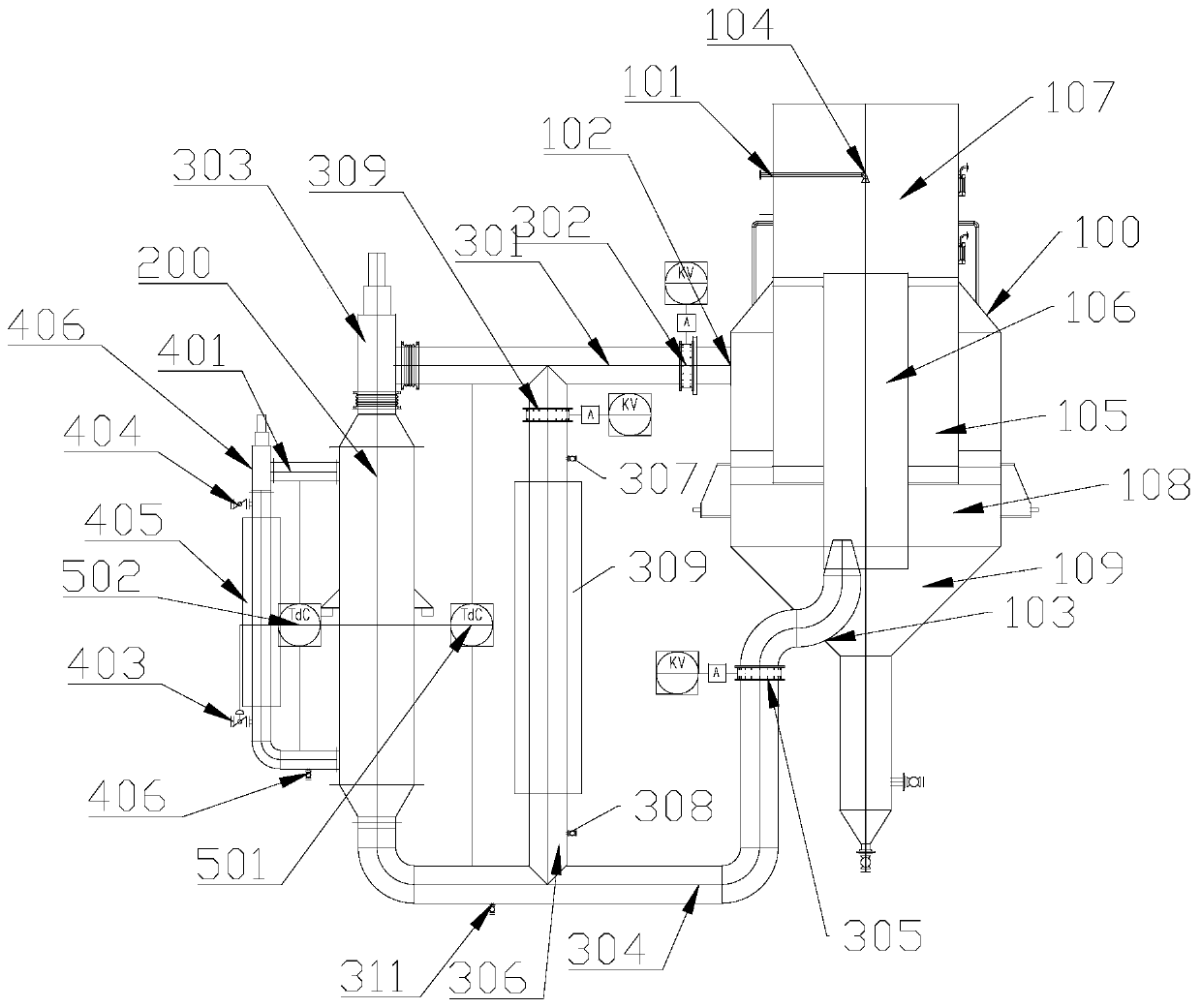

[0050] Such as figure 2 As shown, the continuous frozen crystallizer of the present invention includes a crystal grower 100, an external cooler 200, a material circulation system 300, a refrigerant circulation system 400 and a temperature control system;

[0051] The crystal grower 100 includes a feed mixing section 107, a supernatant liquid settling section 108, and a magma classification section 109 interconnected from top to bottom; Circulation return port 103; stoste feed port 101 is arranged in feed mixing section 107, circulation outlet 102 is arranged in clear liquid settling section 108, and circulation return port 103 is arranged in magma classification section 109; The crystal grower 100 There is also a feed liquid distributor 104, a downcomer 105 and a riser 106 inside; the feed liquid distributor 104 communicates with the raw liquid feed inlet 101, and in this embodiment, the feed liquid distributor 104 is located at Directly above the downcomer 105, and the liqu...

Embodiment 3

[0058] In this embodiment, a salt leg 110 is added on the basis of Embodiment 1 or 2. Specifically, the crystal grower 100 also includes a salt leg 110 connected to the lower end of the magma classification section 109, and the salt leg 110 is provided with a crystal A slurry outlet 111 and an elutriation solution inlet 112 ; in this embodiment, the crystal slurry outlet 111 is located at the upper end of the elutriation solution inlet 112 .

[0059] By setting the salt leg 110, the coarse crystals deposited in the crystal slurry classification section 109 further sink into the salt leg 110, and are discharged through the crystal slurry outlet 111 for solid-liquid separation, and the solid phase obtained by solid-liquid separation is, It is Glauber’s salt product; the mother liquor obtained by solid-liquid separation can be processed in other processes according to the process requirements; it can also be returned to the crystal grower 100 through the top of the crystal grower ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com