Stepped hole method-based internal residual stress measurement method

A technology of internal residual stress and measurement method, which is applied in the direction of force/torque/work measuring instrument, measuring device, instrument, etc., can solve the problems of workpiece damage, difficulty in pasting strain gauges, and enlargement of large hole diameter, etc., so as to prevent damage , high calculation accuracy, convenient and efficient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The present invention is described in further detail below in conjunction with accompanying drawing:

[0041] The internal residual stress measuring method based on the stepped hole method of the present invention comprises the following steps:

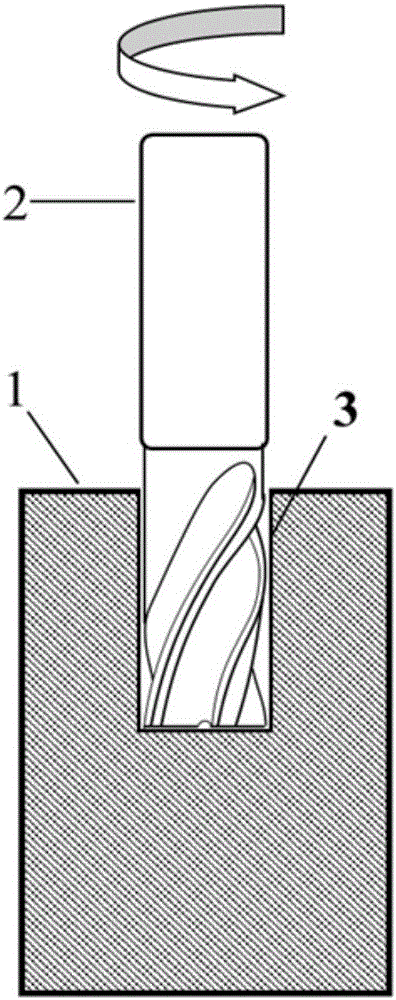

[0042] 1) Using the milling cutter 2 to mill out the concave hole 3 on the end surface of the workpiece 1 to be measured according to the preset measurement depth;

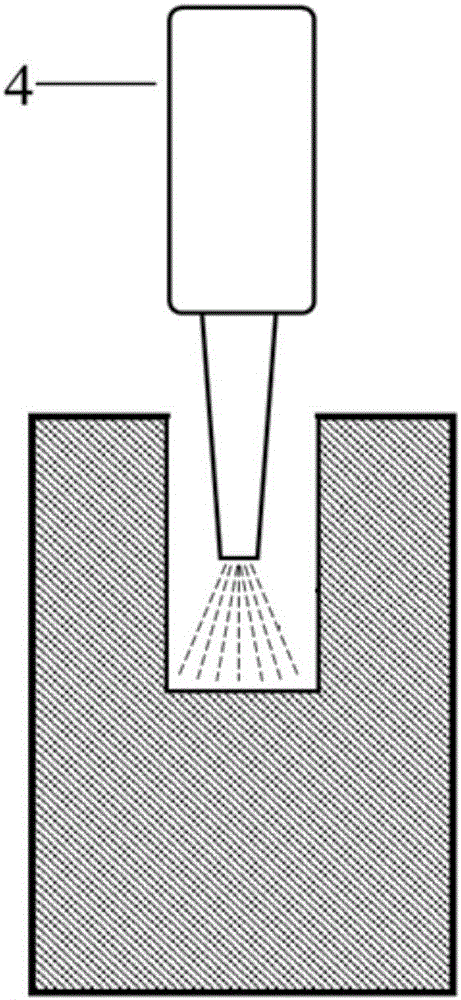

[0043] 2) cleaning the bottom surface of the concave hole 3 for the residue generated during the process of making the concave hole 3, then extending the spray pipe 4 into the concave hole 3, and evenly spraying matt white paint on the bottom of the concave hole 3;

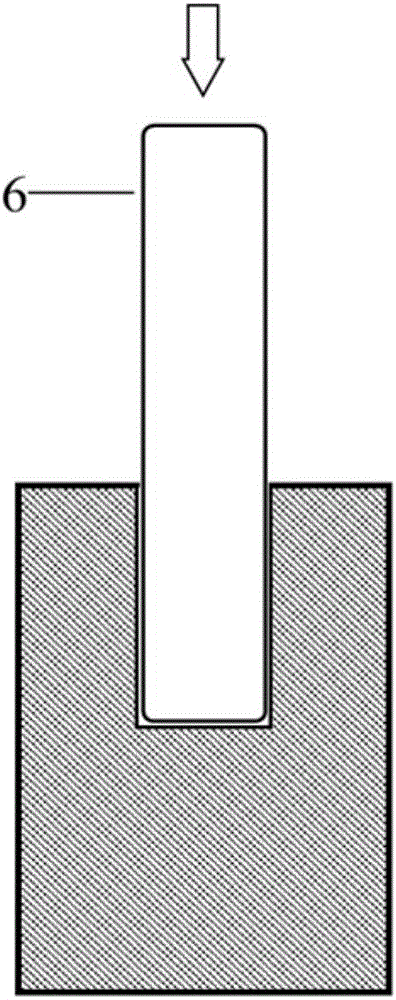

[0044] 3) Make the stamp 6, wherein, the end face of the stamp 6 is engraved with some marking points 7, then the stamp 6 is inserted into the concave hole 3, and the marking points 7 are printed on the bottom surface of the concave hole 3;

[0045] 4) Obtain the initial state information of the marki...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com